Novel target furnace equipment and target bonding method

A technology for target materials and equipment, applied in the field of new target furnace equipment, can solve the problems of high later use risk, low sintering qualification rate, low melting point of indium, etc., and achieve the effects of improving bonding efficiency and simple manual operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

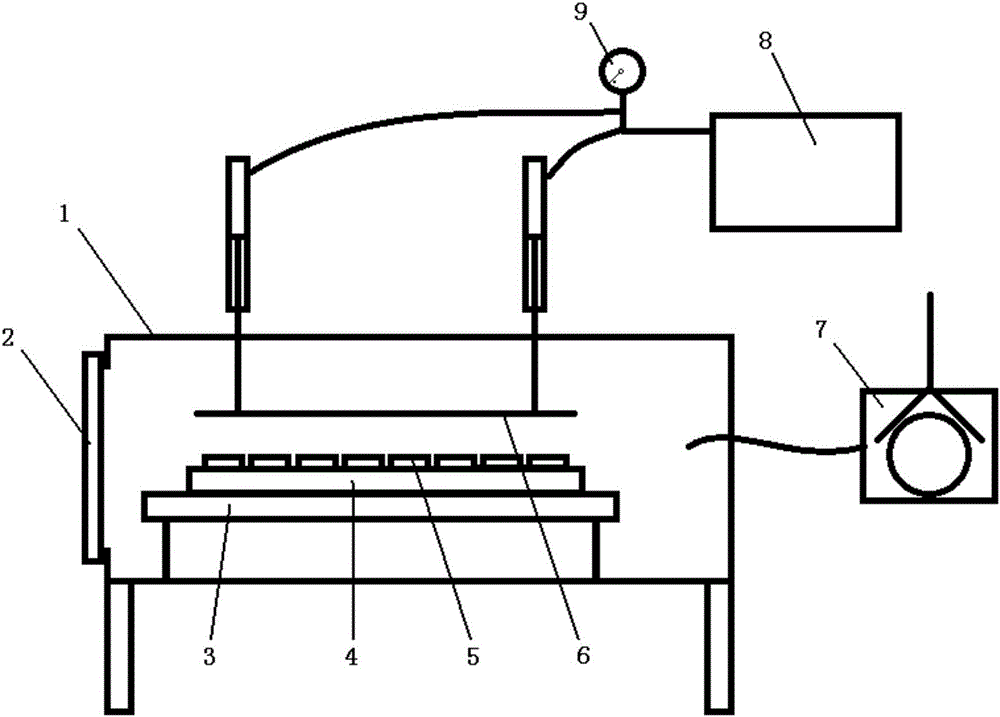

[0028] Such as figure 1 As shown in a new type of target furnace equipment, a furnace door 2 is arranged on one side of the furnace body 1, a heating base 3 is arranged inside the furnace body 1, and a heating device and a temperature detector for temperature control are arranged inside the heating base 3. The heating base 3 is bolted to the target substrate 4 for placing the target 5, and a stainless steel pressure plate 6 is arranged directly above the target substrate 4, and the length and width of the pressure plate 6 are not smaller than the target substrate. The length and width of 4, the upper end of the pressure plate 6 is connected to the hydraulic pump 8 outside the furnace body 1, the hydraulic pump 8 is connected to the pressure gauge 9, and the inside of the furnace body 1 is communicated with the external vacuum pump 7.

Embodiment 2

[0030] A method for target bonding using the novel target furnace equipment described in Example 1: specifically comprising the following steps:

[0031] 1) First install a mold on the target substrate 4 and fix it;

[0032] 2) Place the indium balls in the mold and spread them evenly;

[0033] 3) The target material 5 is placed on the indium ball, and it is closely attached to the mold and fixed to ensure that no displacement occurs during the heating and pressing process;

[0034] 4) Use the hydraulic pump 8 to move down the pressure plate 6 to ensure that the pressure plate 6 and the target 5 are tightly locked, and close the furnace door 2;

[0035] 5) Turn on the vacuum pump 7 to pump the vacuum chamber of the equipment to 10Pa;

[0036] 6) Set the pressure value so that the pressure between the target substrate 4 and the target 5 is always maintained at about 2MPa; turn on the heating function to raise the temperature of the heating base 3 to 156°C;

[0037] 7) After ...

Embodiment 3

[0040] The structure of each part of a new type of target furnace equipment described in this embodiment is the same as that in Embodiment 1, and the different technical parameters are: the material of the pressure plate 6 is polytetrafluoroethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com