Micro heat pipe vacuuming and filling device and method

A technology of micro-heat pipe and vacuuming, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of inaccuracy, high cost of temperature control system, and inability to achieve precise control, etc., and achieve the effect of simple and economical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

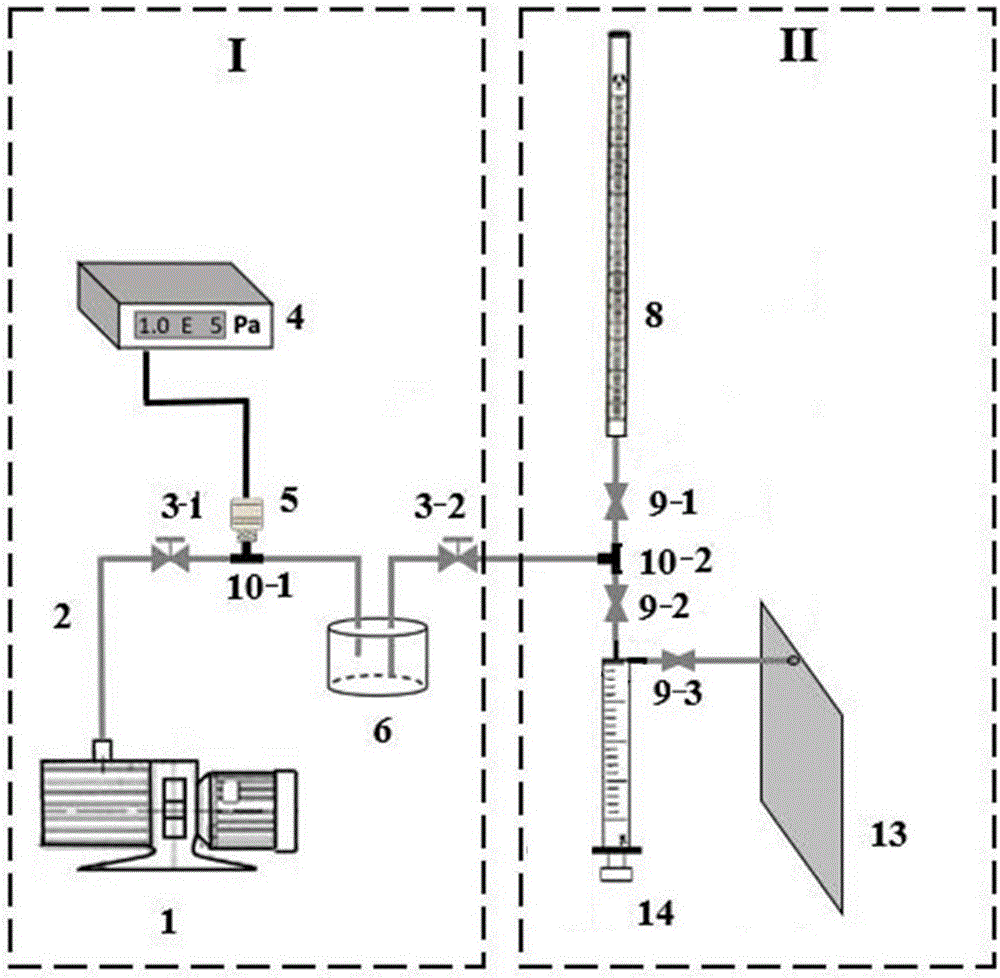

[0030] Such as figure 1 As shown, 1. A micro heat pipe evacuation and filling device is characterized in that it includes a vacuum system I and a filling system II;

[0031] The vacuum system I includes a vacuum pump 1, a metal pipeline 2 and a liquid storage tank 6, one end of the vacuum pump 1 is connected to one end of a section of metal pipeline 2, and the other end of the metal pipeline 2 is placed in the liquid storage tank 6, the port is always above the liquid level in the liquid storage tank 6;

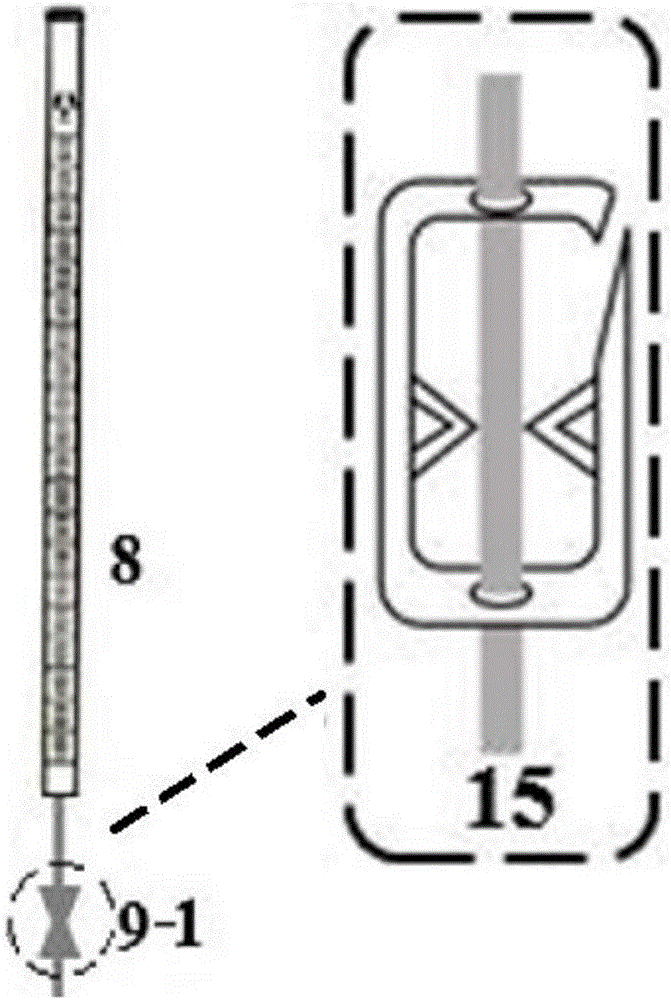

[0032] The filling system II includes a burette 8, a micro-injector 14, a transparent silicone hose 15, and a micro-heat pipe 13;

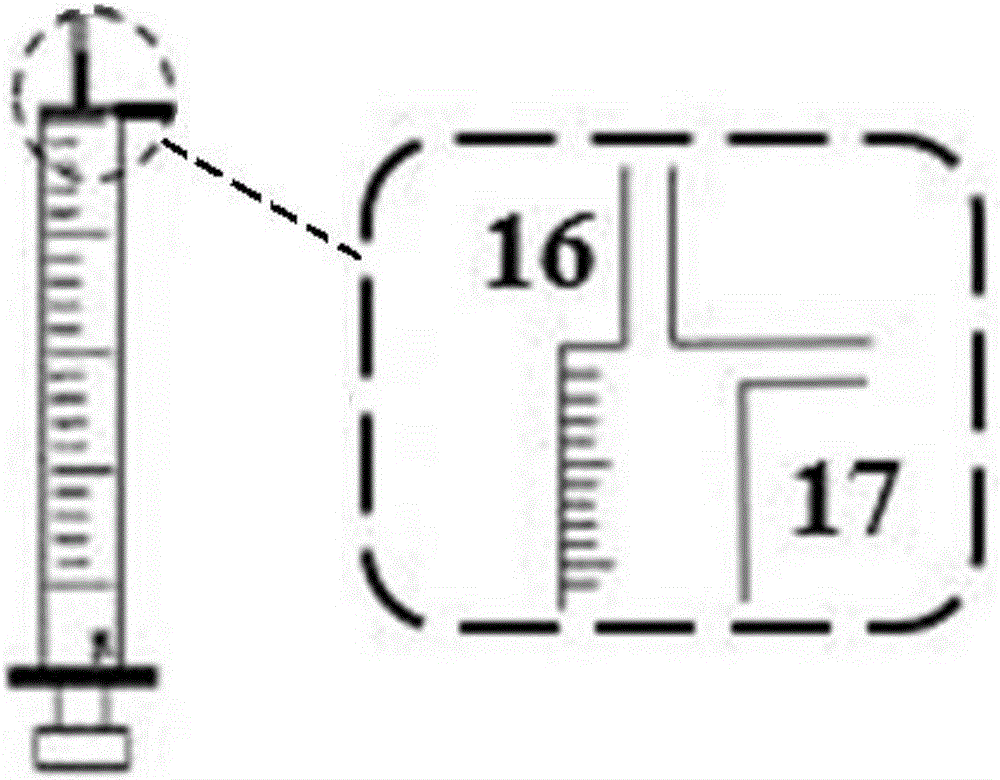

[0033] Such as figure 2 As shown, the microinjector 14 includes a fluid inlet 16 and a fluid outlet 17;

[0034] The burette 8 is connected to one end of the tee B10-2 through a transparent silicone hose 15, and this section of the transparent silicone hose 15 is clamped with a Robert hose clamp A9-1;

[0035] One end of another section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com