Method for measuring multi-axis strain of thin-walled tube under internal pressure axial composite load

A technology of strain measurement and compound load, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of cumbersome steps of strain gages, cumbersome steps of use, expensive strain gages, etc., and achieve good dynamic response characteristics and convenient installation and maintenance , the real effect of the test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

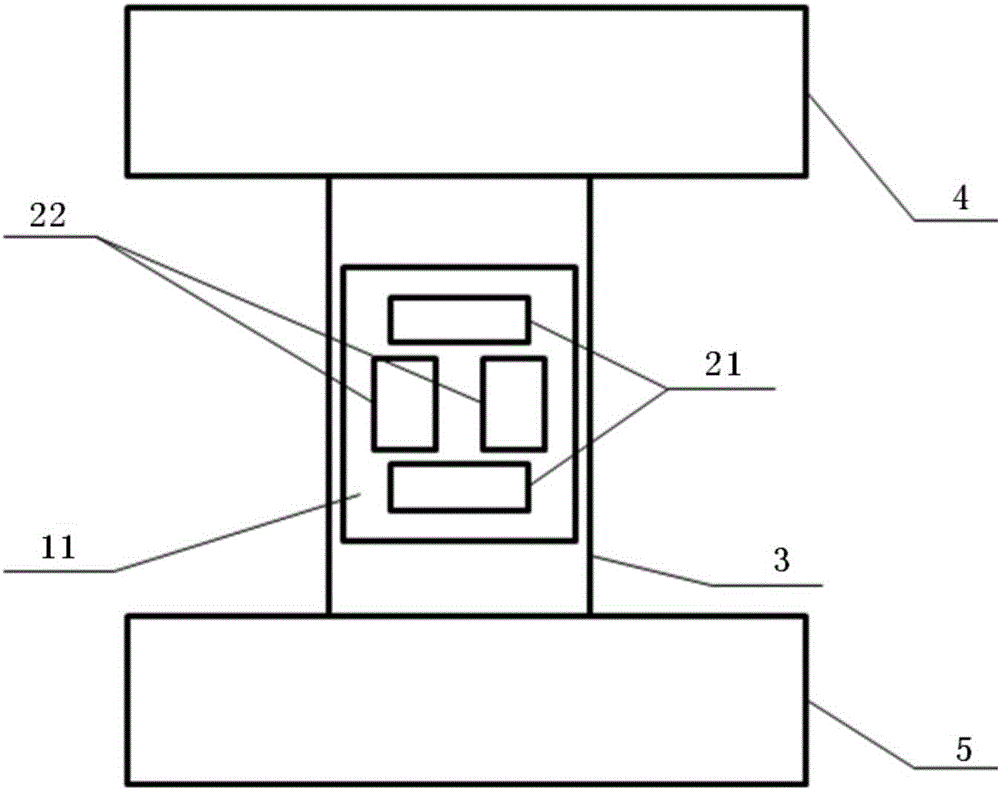

[0034] A method for measuring multiaxial strain of a thin-walled pipe under internal pressure and axial compound load of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0035] A method for measuring the multiaxial strain of a thin-walled pipe under an internal pressure axial composite load of the present invention comprises the following steps:

[0036] 1) Make a standard test mark on the surface of the measured thin-walled tube as a reference for image processing; including:

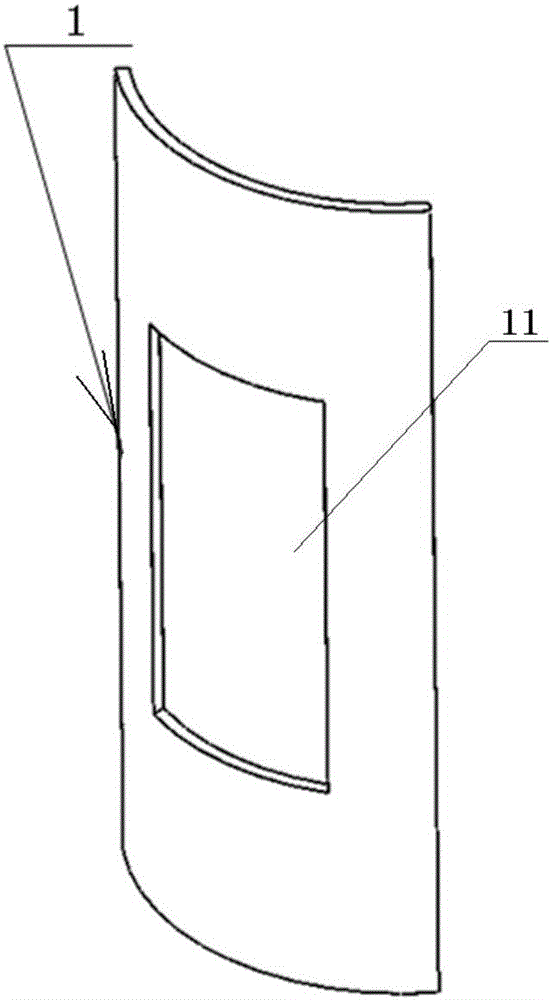

[0037] (1) On the surface cover of the thin-walled tube to be tested, such as figure 2 The shown primer mask 1 for spraying the primer is sprayed with white paint at the primer spraying position 11 of the primer mask 1 to form the background of the standard test mark, which is used to enhance the edge and background of the thin-walled pipe under test. contrast, and then remove the primer mask plate 1;

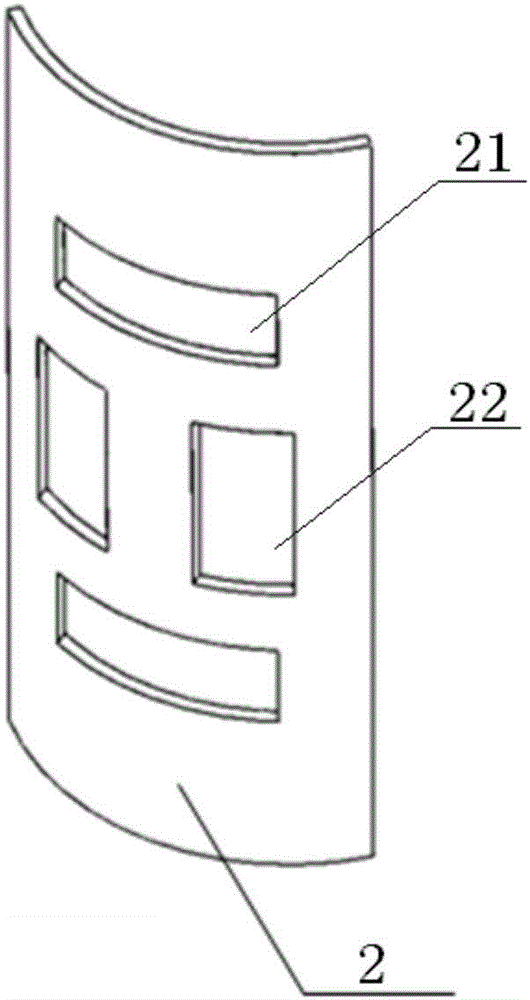

[0038] (2) After the wh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap