Steel mesh hole-cutting accuracy detection device

A detection device and precision technology, which are applied in the field of detection devices for the accuracy of stencil openings to achieve precise opening size and shape and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

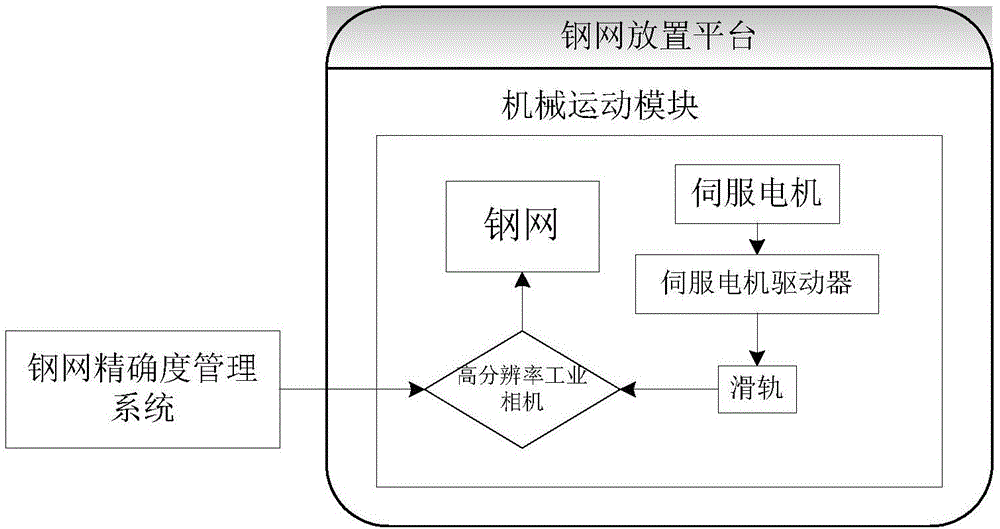

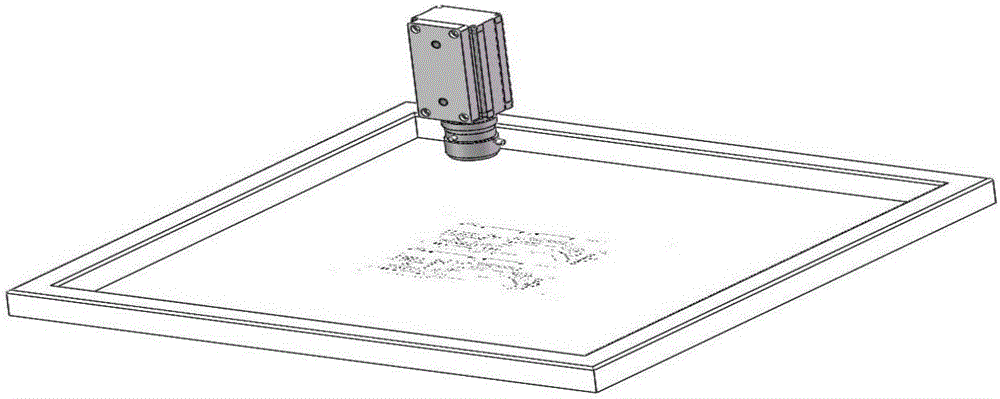

[0012] This embodiment provides a detection device for the accuracy of stencil opening, which specifically includes: a stencil management system, a high-resolution industrial camera, a stencil placement platform, and a mechanical movement module; the stencil management system has a built-in motion control card , the mechanical motion module is equipped with a servo motor, a slide rail and a servo motor driver, and the servo motor driver is connected to the servo motor and the slide rail respectively; wherein the high-resolution industrial camera is placed on the mechanical motion module, and the steel mesh is placed On the stencil placement platform, the stencil management system is connected to the high-resolution industrial camera through the USB2.0 interface, and the high-resolution industrial camera is also connected to the stencil and the slide rail.

[0013] The operator imports the Gerber data corresponding to the substrate into the stencil management system in advance, ...

Embodiment 2

[0015] This embodiment provides a method for detecting the accuracy of steel mesh openings, which specifically includes:

[0016] S1: The operator imports the Gerber data corresponding to the substrate into the stencil management system, and the stencil management system draws a 1:1 ratio with the real substrate based on the substrate size, MARK point position, pad shape and size information in the Gerber data template information;

[0017] S2: The stencil is placed on the stencil placement platform. The color of the platform is dark. When shooting with a high-resolution industrial camera, the stencil management system drives the servo motor driver in the mechanical movement module through the motion control card;

[0018] S3: The servo motor driver drives the high-resolution industrial camera on the slide rail to acquire image information at different positions on the substrate;

[0019] S4: The stencil management system extracts information such as the opening and shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com