Fiber grating dislocation gauge with wedge-shaped structure

A fiber grating and wedge-shaped technology, which is used in measuring devices, instruments, surveying and mapping, and navigation, etc., can solve the problems affecting the normal supply of electricity, gas heating, etc., the settlement deformation of underground comprehensive pipe gallery, engineering pipeline deformation, etc., and achieve monitoring results. Real and reliable, fast response, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited by the specific examples.

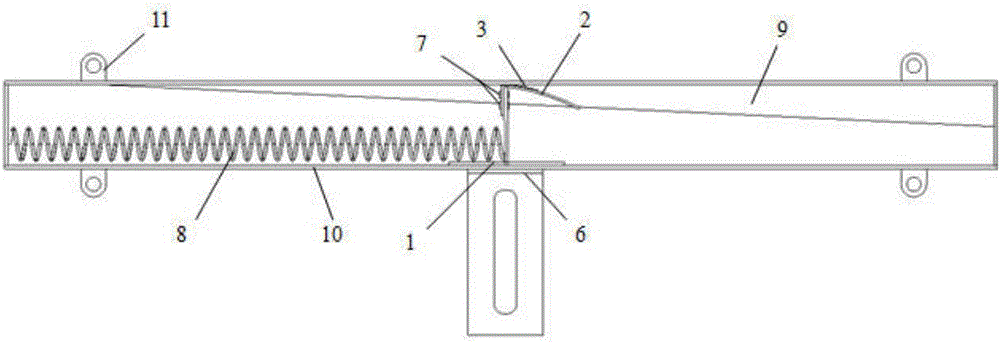

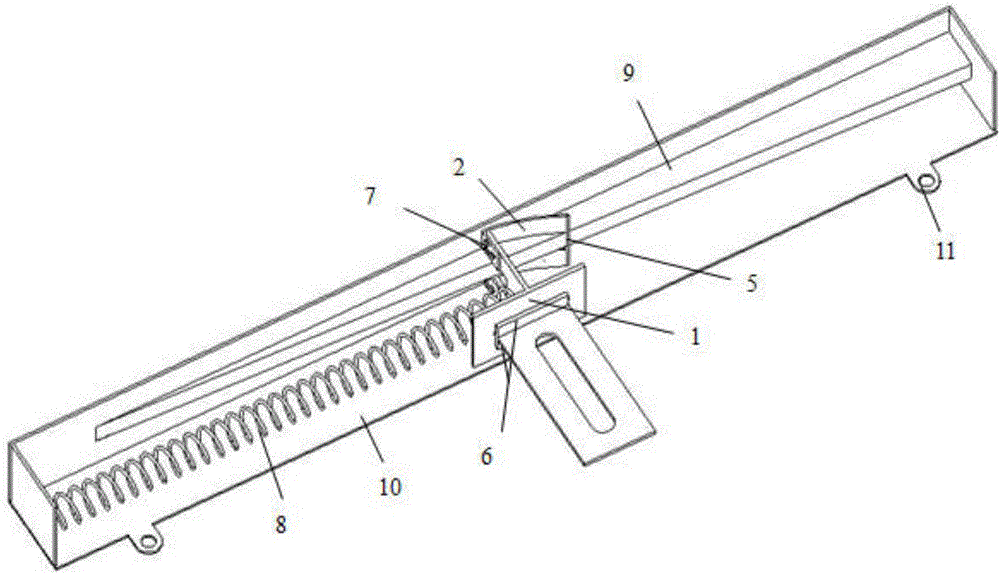

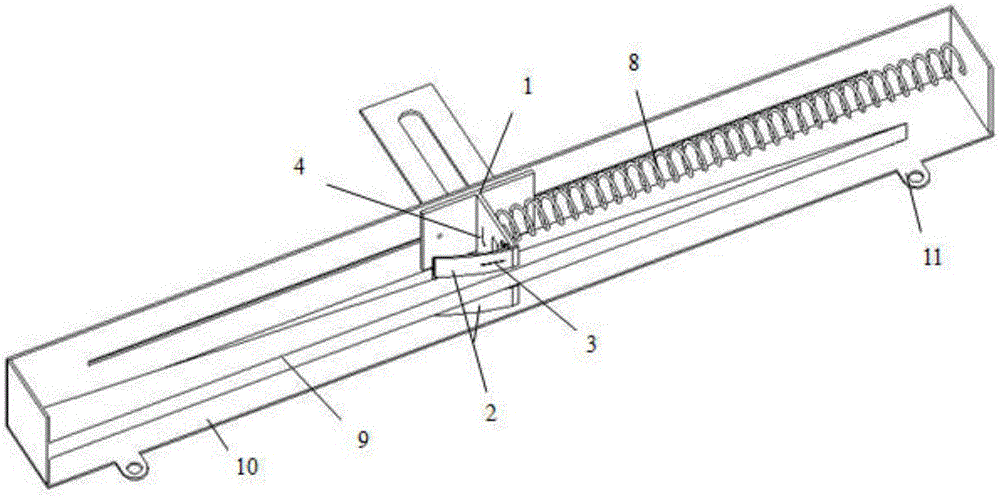

[0027] Figure 1-6 shown. A wedge-shaped fiber grating dislocation meter, including a sliding head 1, a cantilever beam 2, a sensing fiber grating 3, a compensation fiber grating 4, a transmission rod 5, a limit plate 6, a bolt 7, a wedge block 9, a spring 8, Protective shell 10 and fixed sheet 11;

[0028] The protective shell 10 is a rectangular box, and the side wall is provided with a narrow and long movable seam for the sliding head 1 to protrude, and the side of the protective shell 10 corresponding to the movable seam is fixed with a wedge-shaped block 8;

[0029] The end of the sliding head 1 is a U-shaped plate structure, and the U-shaped plate is clamped on the wedge-shaped block 8; two cantilever beams 2 are fixed on the U-shaped plate through bolts; the movable en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com