Plugging pressure testing device and plugging pressure testing method applicable to middle and high pressure gas pipes

A gas pipe, medium and high pressure technology, applied in the direction of measuring device, fluid tightness test, machine/structural component test, etc., can solve the problems of complicated operation of the pressure test device, long time required, complicated on-site conditions, etc., to achieve The effect of simple structure, improved efficiency and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

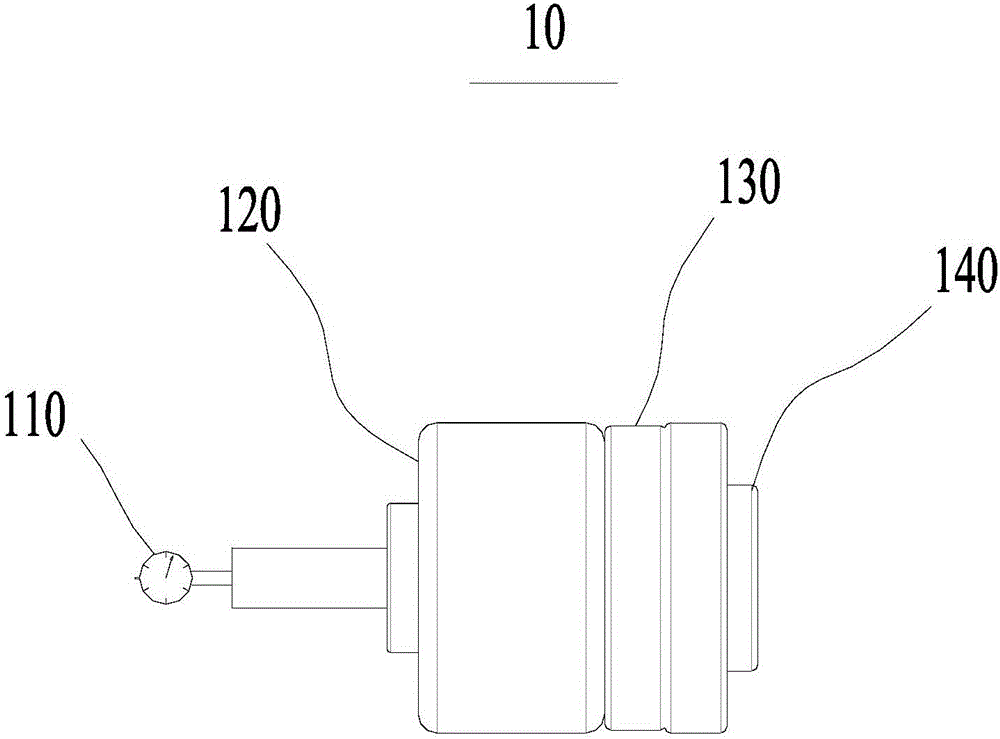

[0038] Please refer to figure 1 , figure 1 A plugging and pressure testing device 10 suitable for medium and high pressure gas pipes, which will be described in detail below, is shown. It can be seen from the figure that the plugging and pressure testing device 10 suitable for medium and high pressure gas pipes mainly includes a detection device 110 , a power device 120 , an elastic pad 130 and a pressure plate 140 .

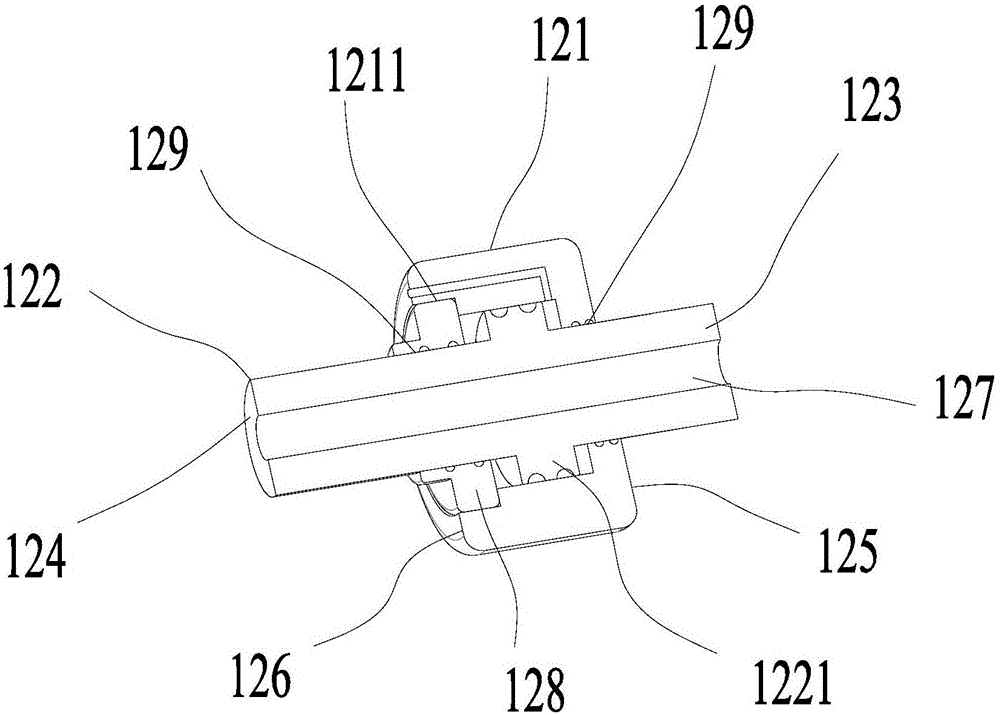

[0039] Please refer to figure 2 , figure 2 The main structure of the power device 120 is shown. The power device 120 mainly includes a cylinder body 121, a cylinder head 128, a piston 1221 and a piston rod 122. The inside of the cylinder body 121 is a hollow chamber, and the cylinder body 121 has a first end surface 125 and The second end face 126, the second end face 126 is provided with the cylinder head mounting hole 1211 for installing the cylinder head 128, the first end face 125 and the cylinder head 128 are provided with a piston rod passing hole 129...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com