Double rotor test machine for cylindrical roller bearings

A technology of cylindrical roller bearings and double rotors, which is applied in the direction of mechanical bearing testing, etc., and can solve the problems of low limit speed, no large size, high speed and large load cylindrical roller bearing test double rotor testing machine, harsh working environment, etc. , to achieve the effect of increasing the maximum speed, high positioning accuracy, and good loading smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be specifically described below with reference to the accompanying drawings.

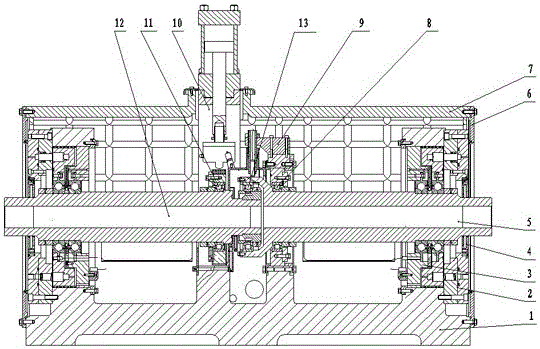

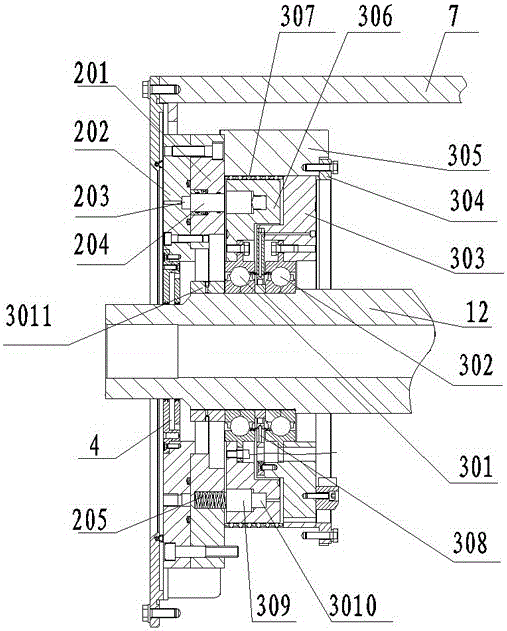

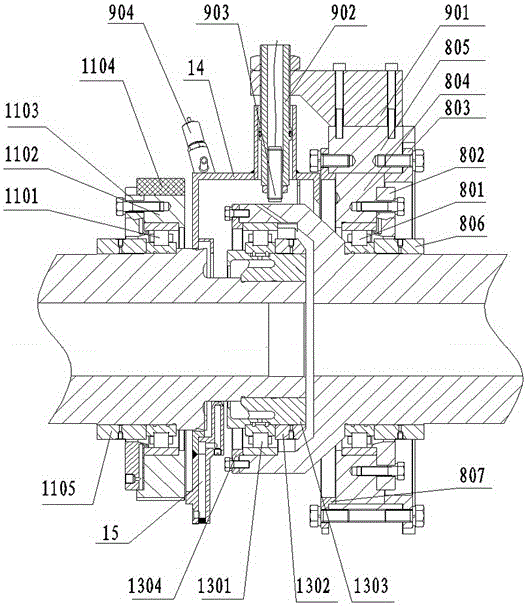

[0043] A cylindrical roller bearing double-rotor testing machine, comprising a body base 1, a rotor shaft arranged on the body base 1, a radial loading device 10 arranged above the rotor shaft and fixedly connected to the body base 1, and a monitoring device 9, the rotor A first accompanying test device 11 , a test bearing tooling 13 and a second accompanying test device 8 are sequentially arranged on the shaft, and a supporting device 3 is respectively provided at both ends of the rotor shaft.

[0044] The rotor shaft is composed of an inner ring rotor shaft 12 and an outer ring rotor shaft 5, and both the inner ring rotor shaft 12 and the outer ring rotor shaft 5 are hollow shafts. The test bearing tooling 13 is composed of a test bearing 1301, a fourth stepped sleeve 1302, an under-ring lubricating sleeve 1303 and a test bearing pressure ring 1304,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com