Reverse reduction method of radial tire structure

A radial tire and tire technology, applied in the direction of automobile tire testing, etc., can solve problems such as inability to analyze performance and restore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

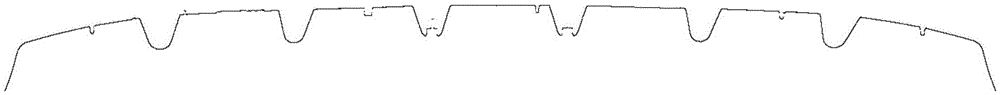

[0047] Taking the 445 / 45R19.5 tire as this example, according to the implementation steps of the present invention, the tire is first installed on the standard rim of 19.5×15.00, filled with an air pressure of 0.1MPa, and the rim is fixed. After 24 hours, etc. The crown profile is measured 4 times at intervals, and the measured crown profile curve is as follows figure 2 shown. The measured radius of the highest position of the tread is 448mm.

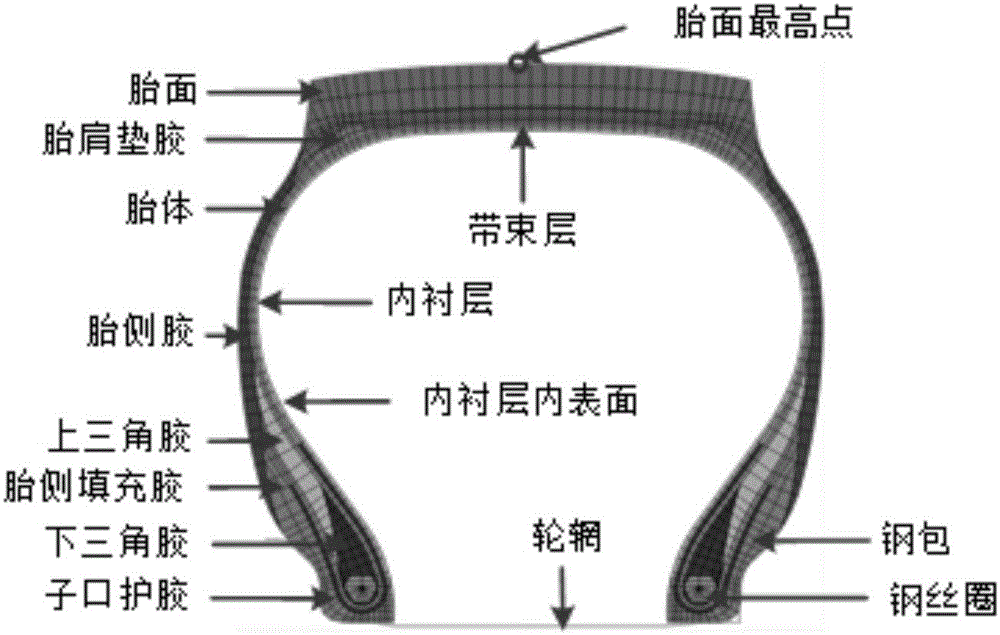

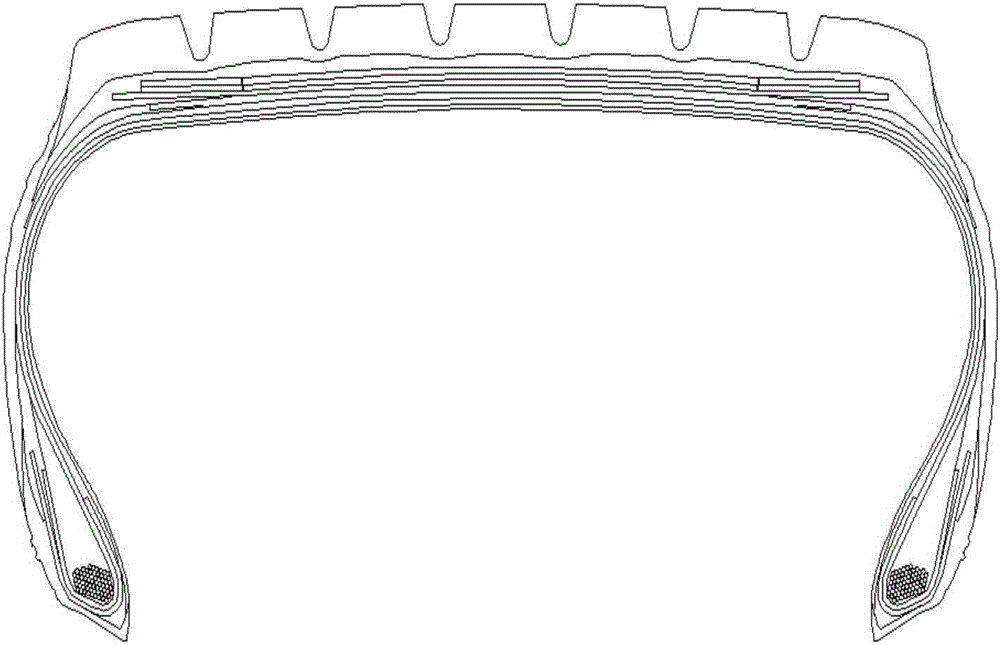

[0048] Cut the section of the tire, stick the bead to the inner wall of the 9.5×15.00 rim, take 1 / 180 of the section, and manually draw the internal structure, such as image 3 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com