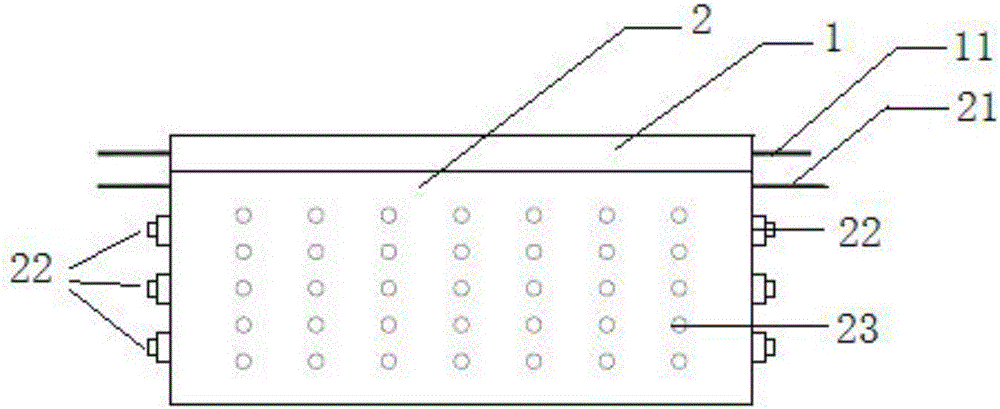

Multifunctional heterogeneous core model equipment

A core model and heterogeneous technology, which is applied in the field of multi-functional heterogeneous core model equipment, can solve problems such as inability to simulate oil layer characteristics well, and achieve the effects of correcting model permeability, good simulation effect and widening function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

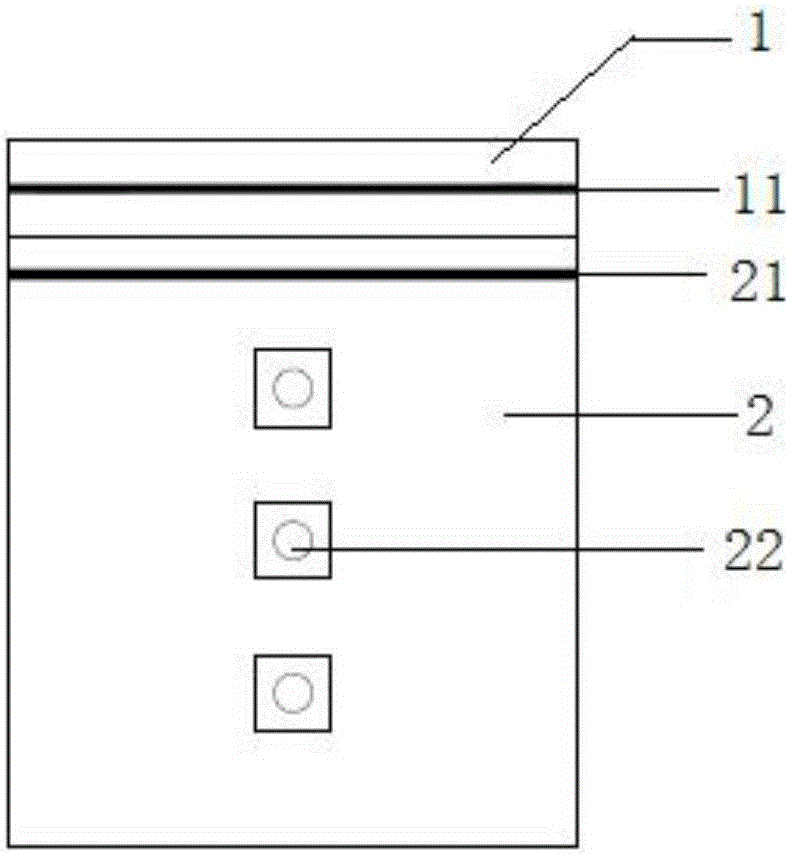

Method used

Image

Examples

Embodiment

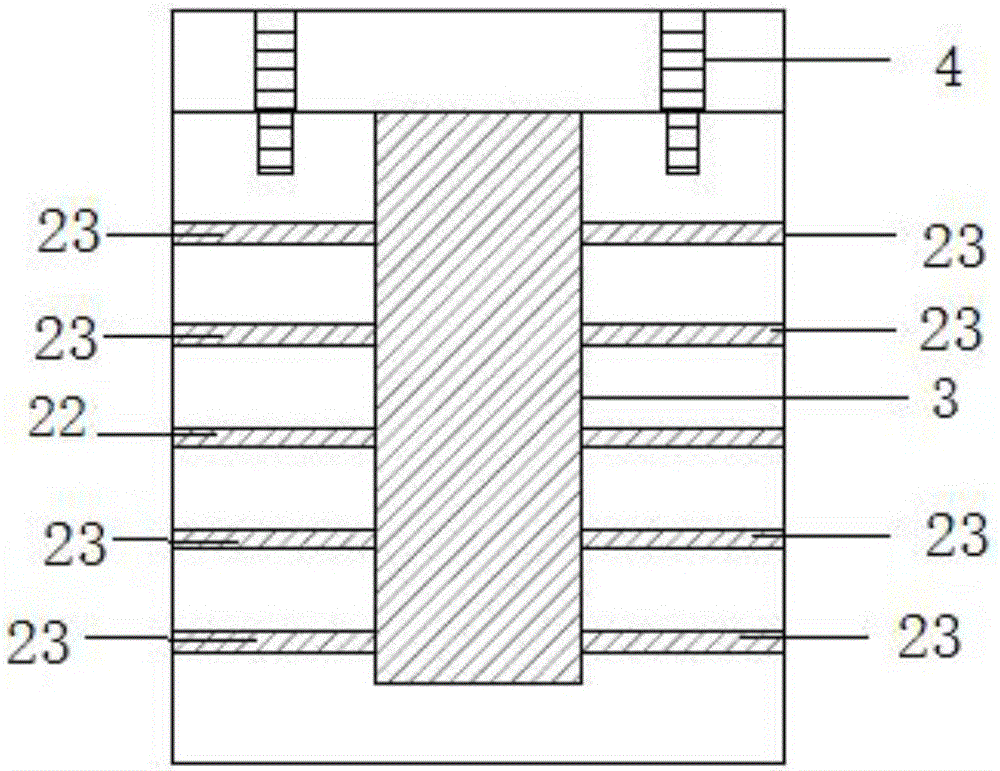

[0038] (1) Carry out the assembly of the model:

[0039] ①Put the cover plate on the O-ring, apply lubricating oil, and set aside;

[0040] ② Prepare the electrodes and embed them in the model for fixation;

[0041] ③ Install the inlet and outlet valves;

[0042] ④Sand filling operation: Generally, sand filling is divided into three times, and 400g of quartz sand of different meshes are filled each time (the first layer is 120-160 mesh, the second layer is 80-100 mesh, and the third layer is 60-80 mesh). There are three layers of heterogeneous cores, and each layer uses a scraping tool (such as Figure 7 As shown) after scraping, add the next layer of quartz sand for scraping. After the three layers are added, use a ruler to measure, and the forging operation can be performed 0.3cm above the grinding surface (multiple test results show that 0.3cm), and use the corresponding pressing mold 50MPa constant pressure for 5 minutes, and finally put into the mold combination moldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com