Single-motor-driven handheld ultrasonic automatic scanner for solder joints

A single-motor-driven, hand-held technology, applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc. problems, to achieve the effect of reducing size requirements, volume reduction, and high scanning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

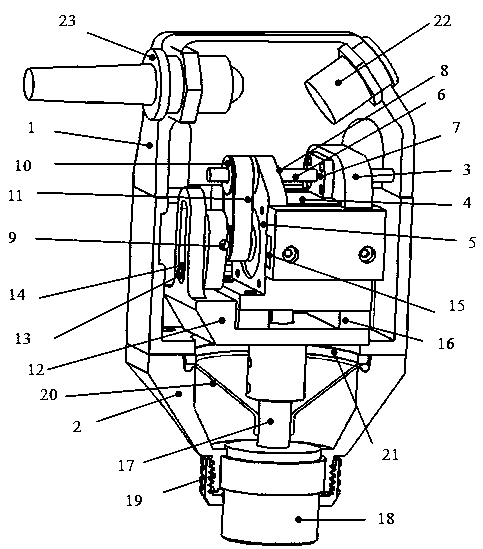

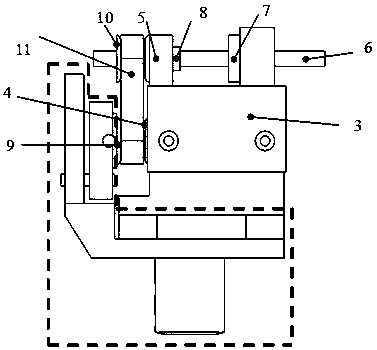

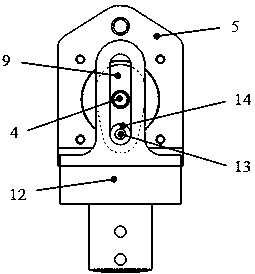

[0024] Taking the detection of a MIG welding spot workpiece with a diameter of 15mm as an example, the details of the present invention and its specific implementation will be further described in conjunction with the accompanying drawings.

[0025] see Figure 1 to Figure 6 As shown, the single-motor-driven hand-held ultrasonic automatic scanner for solder joints of the present invention includes a housing module, an X-Y bidirectional movement module, an ultrasonic transmitting / receiving module and an accessory module, wherein the housing module is the basis for connection and fixing, The X-Y two-way movement module and the accessory module are fixed on the shell module; the X-Y two-way movement module has a built-in single motor drive device to realize the X-Y direction scanning movement; the ultrasonic transmitting / receiving module is fixed on the X-Y two-way movement module, so that the ultrasonic probe is on the surface of the workpiece Carry out X-Y direction scanning; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com