Triangular-array ultrasonic wind detecting sensor

A technology of wind sensor and ultrasonic transducer, which is applied in the direction of instruments, measuring devices, fluid velocity measurement, etc., can solve the problems of wind field influence, measurement accuracy reduction, and measurement cycle extension, so as to avoid occlusion and strong adaptability , improve accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

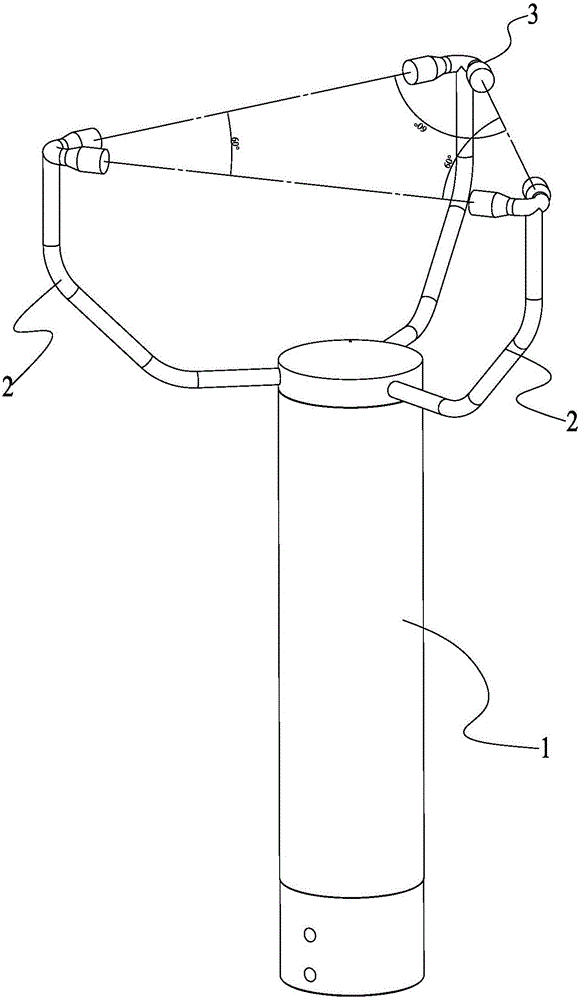

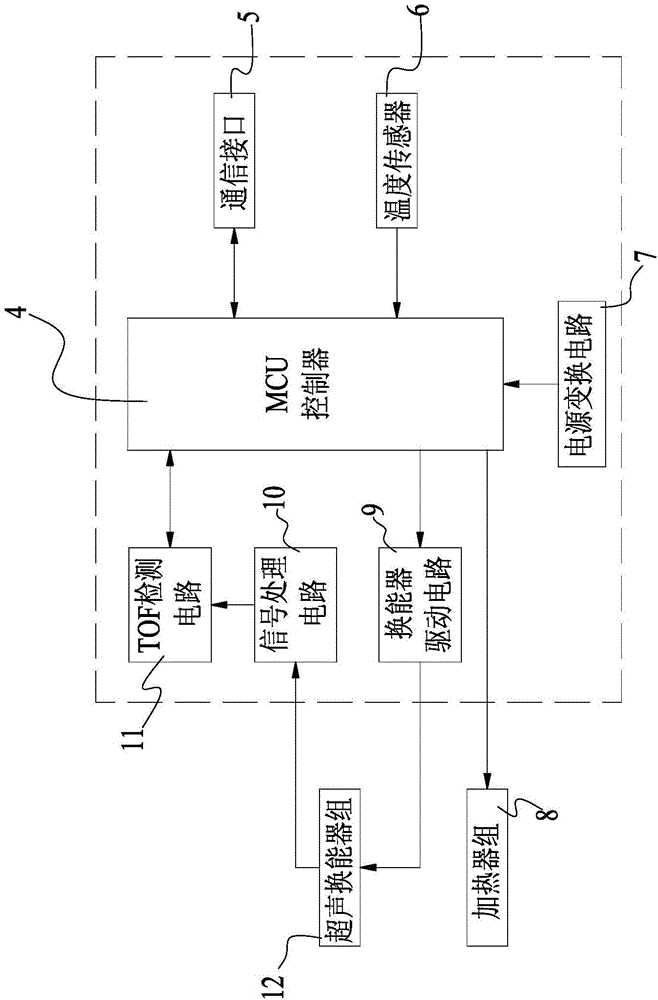

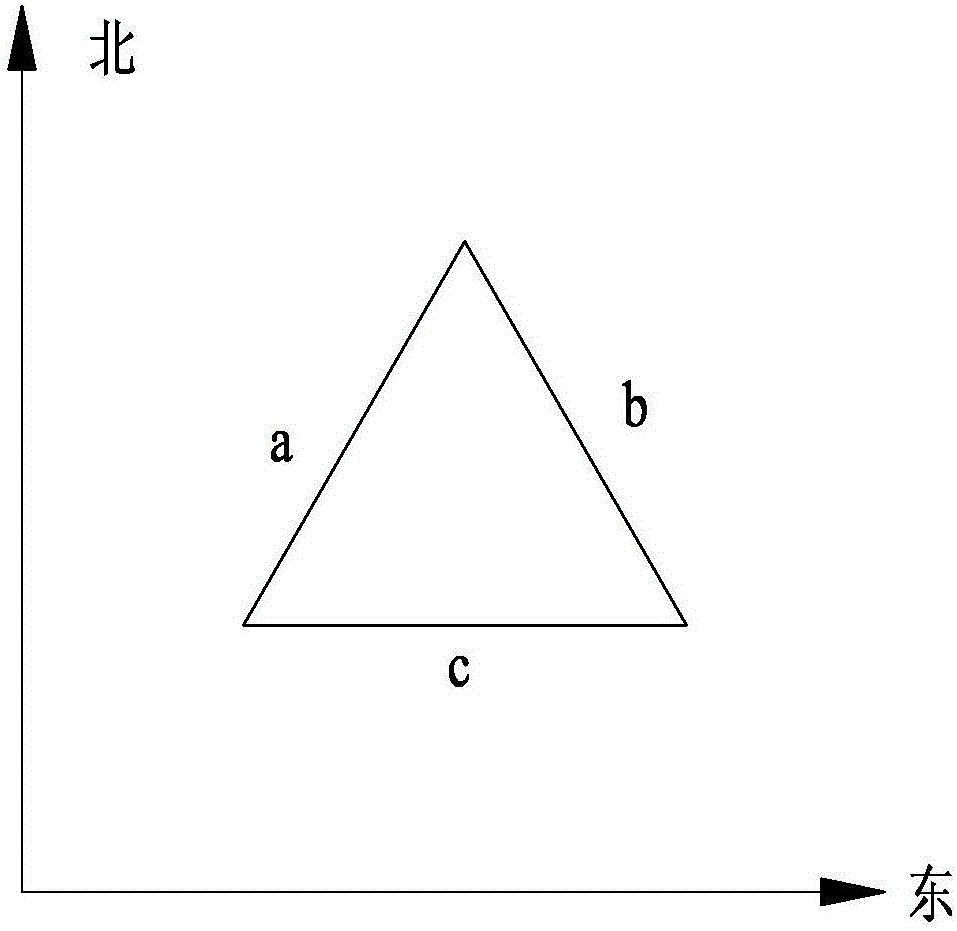

[0020] In order to realize the effective measurement of wind speed and improve the accuracy and stability of the measurement, the present invention includes three groups of ultrasonic transducer groups 12, and the three groups of ultrasonic transducer groups 12 are distributed in an equilateral triangle. Two ultrasonic transducers 3 are included in the group 12, and the two ultrasonic transducers 3 in the same ultrasonic transducer group 12 are located on a side of the aforementioned equilateral triangle; The control module is connected, and the wind measurement main control module can drive the ultrasonic transducer 3 to work;

[0021] For two ultrasonic transducers 3 in the same ultrasonic transducer group 12, the main control module of wind measurement can drive one ultrasonic transducer 3 to emit ultrasonic waves, and receive the emitted ultrasonic waves th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com