Mass-type rain gauge-based automatic calibration device and mass-type rain gauge-based automatic calibration method

A technology for verification devices and rain gauges, applied in the direction of climate sustainability, instruments, ICT adaptation, etc., can solve problems such as complex error sources, limiting device work efficiency, and heavy workload, so as to achieve excellent performance, improve automatic detection and guarantee High level and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the technical means and effects adopted by the present invention, the following describes in detail an automatic rainfall verification device based on quality measurement in conjunction with preferred embodiments and accompanying drawings.

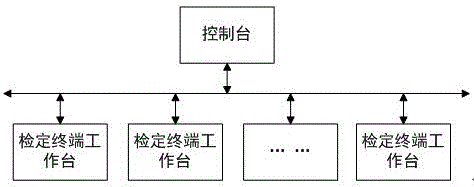

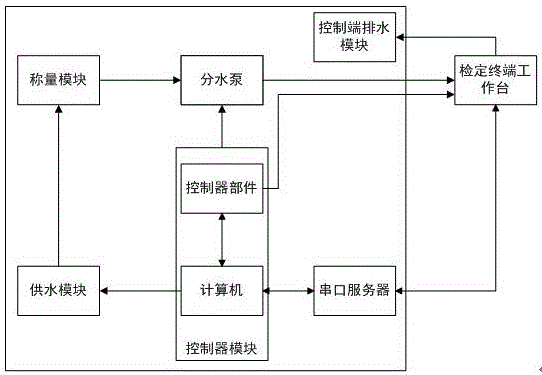

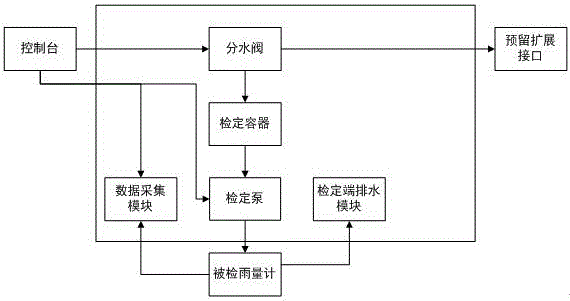

[0021] Such as Figure 1~8 As shown, a console 2 of an automatic rainfall verification device based on quality measurement and several verification terminal workbenches 6, the console 2 is connected to select Sartorius 6010-1CN precision electronic balance as an electronic balance 16 for regular verification Located at the bottom, a weighing container 15 is placed on the weighing pan, and there is a partition above the weighing container 15, which is used to install the water inlet and outlet pipes, the water temperature sensor 14 and the photoelectric liquid level switch. The partition is fixed on the cabinet, and the weighing container 15 No contact, to ensure that the regularly verified electronic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com