Low stray light crosstalk type optical fiber image transmission component and manufacturing method thereof

An astigmatism crosstalk type, optical fiber image transmission technology, which is applied in the direction of bundled optical fiber, etc., can solve the problems of inability to meet the application requirements of optical fiber image transmission components, low stray light absorption efficiency, unclear imaging, etc., to improve imaging clarity, noise The effect of reducing astigmatism crosstalk and high imaging definition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Another embodiment of the present invention proposes a method for preparing a low stray light crosstalk optical fiber image transmission element, which includes the following steps:

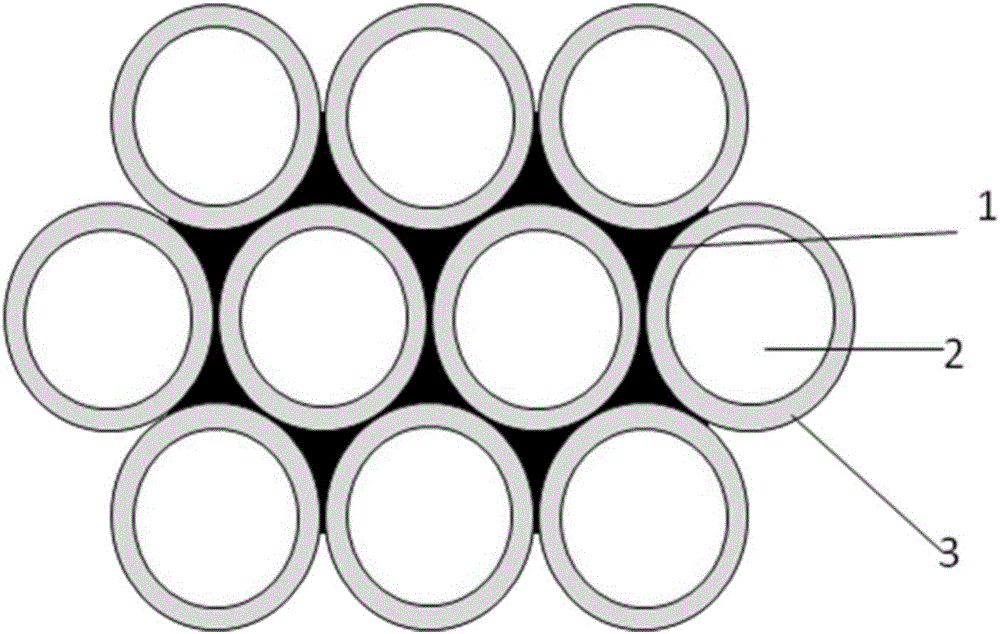

[0038] (1) Process high-refractive-index fiber core glass, low-refraction-index skin glass, and light-absorbing glass into cylindrical core glass rods, skin glass tubes, and light-absorbing glass rods respectively; insert the core glass rods into Inside the leather glass tube, heated and drawn into a cylindrical single optical fiber; wherein the core glass rod and the leather glass tube are closely attached; the light-absorbing glass rod is heated and drawn into a light-absorbing glass filament;

[0039] (2) Arrange the single optical fibers in parallel, and tightly stack them into multiple layers and place them in a row of rod moulds, insert the light-absorbing glass filaments into the gaps between the single optical fibers to obtain optical fiber bundles, and place the Bundle the optical...

Embodiment 1

[0050] (1) The refractive index is 1.65, the softening temperature is 700°C, and the expansion coefficient is 70×10 -7 High-refractive-index core glass at / °C, with a refractive index of 1.45, a softening temperature of 670°C, and an expansion coefficient of 60×10 -7 / ℃ low refractive index leather glass and softening temperature is 550℃, expansion coefficient is 85×10 -7 The light-absorbing glass at / ℃ is processed into cylindrical core glass rods, leather glass tubes, and light-absorbing glass rods; the core glass rods are inserted into the skin glass tubes, heated and drawn into cylindrical single optical fibers; Wherein the core glass rod and the skin glass tube are closely attached; the light-absorbing glass rod is heated and drawn into a light-absorbing glass filament; wherein, the light-absorbing glass component is (by weight percentage): SiO 2 :60%, B 2 o 3 : 5%, ∑(Na 2 O+K 2 O): 15%, ∑(MgO+CaO+BaO): 10%, Fe 2 o 3 : 1%, Co 2 o 3 : 3%, Ni 2 o 3 : 5%, MnO 2 :...

Embodiment 2

[0056] (1) The refractive index is 1.95, the softening temperature is 750°C, and the expansion coefficient is 80×10 -7 / ℃ high refractive index core glass, the refractive index is 1.65, the softening temperature is 700℃, and the expansion coefficient is 80×10 -7 / ℃ low refractive index skin glass and softening temperature is 600℃, expansion coefficient is 100×10 -7 The light-absorbing glass at / ℃ is processed into cylindrical core glass rods, leather glass tubes, and light-absorbing glass rods; the core glass rods are inserted into the skin glass tubes, heated and drawn into cylindrical single optical fibers; Wherein the core glass rod and the leather glass tube are closely attached; the light-absorbing glass rod is heated and drawn into a light-absorbing glass filament; wherein, the light-absorbing glass component is (by weight percentage): SiO 2 :70%, B 2 o 3 : 2%, ∑(Na 2 O+K 2 O): 10%, ∑(MgO+CaO+BaO): 5%, Fe 2 o 3 : 2%, Co 2 o 3 : 3%, Ni 2 o 3 : 4%, MnO 2 : 3%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com