Display panel compatible with multiple types of frame sizes and light-on test method of display panel

A display panel and size technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of increasing the panel process time and increasing the cost of the mask, and achieve the effect of reducing the cost of the mask, increasing the production capacity, and reducing the process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

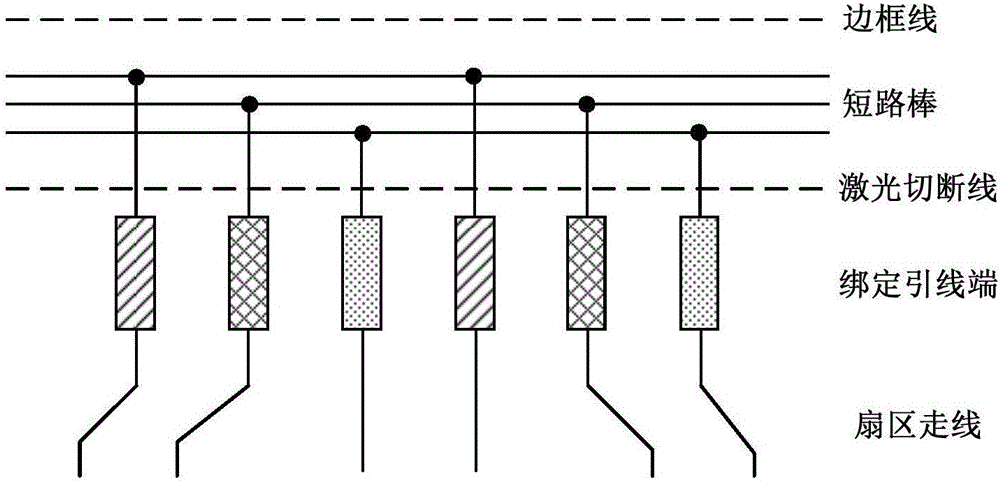

[0033] This embodiment is described by taking the wiring on the side of the source driving circuit of a display panel compatible with two frame sizes as an example.

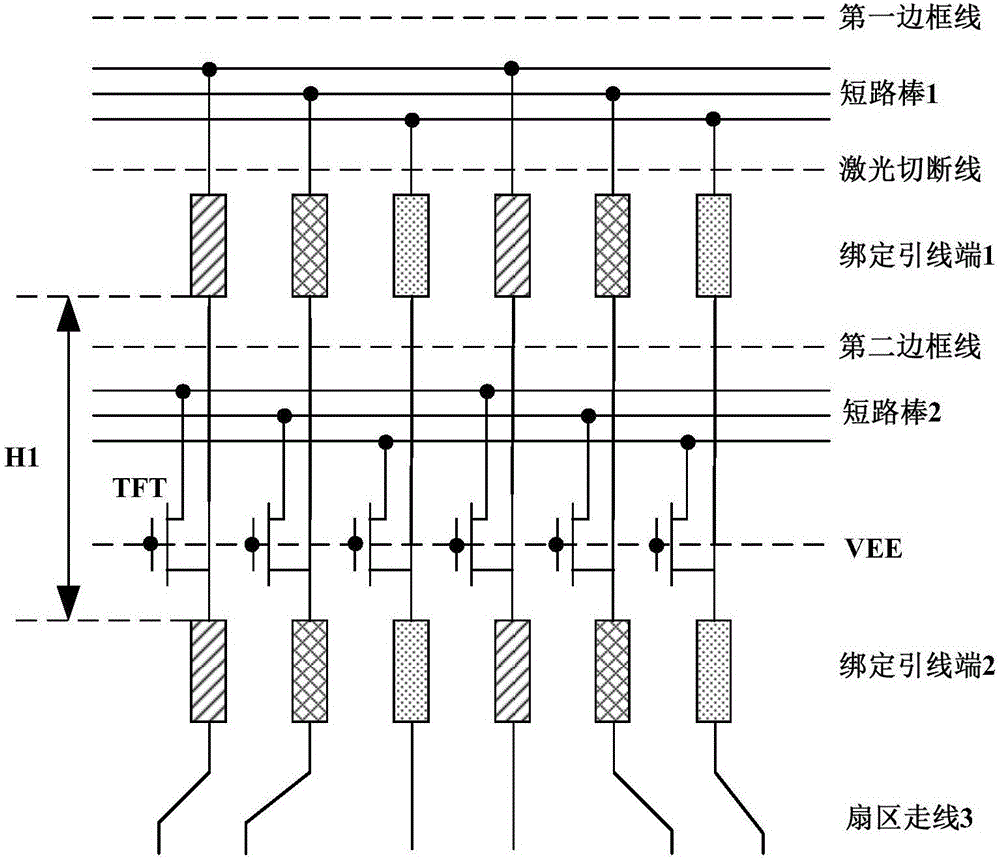

[0034] figure 2 It is a structural schematic diagram of a display panel compatible with multiple frame sizes according to the first embodiment of the present invention. As shown in the figure, the first dotted line from top to bottom in the figure is the frame line corresponding to the first frame size. Panels are wide bezels. The third dotted line is the border line corresponding to the second border size, and the display panel has a narrow border at this time.

[0035] The display panel in this embodiment is used to be compatible with the first frame size and the second frame size, assuming that the first frame size is larger than the second frame size. Such as figure 2As shown, each binding lead end 1 corresponding to the first frame size is connected to the terminal at the corresponding bit sequence of e...

no. 2 example

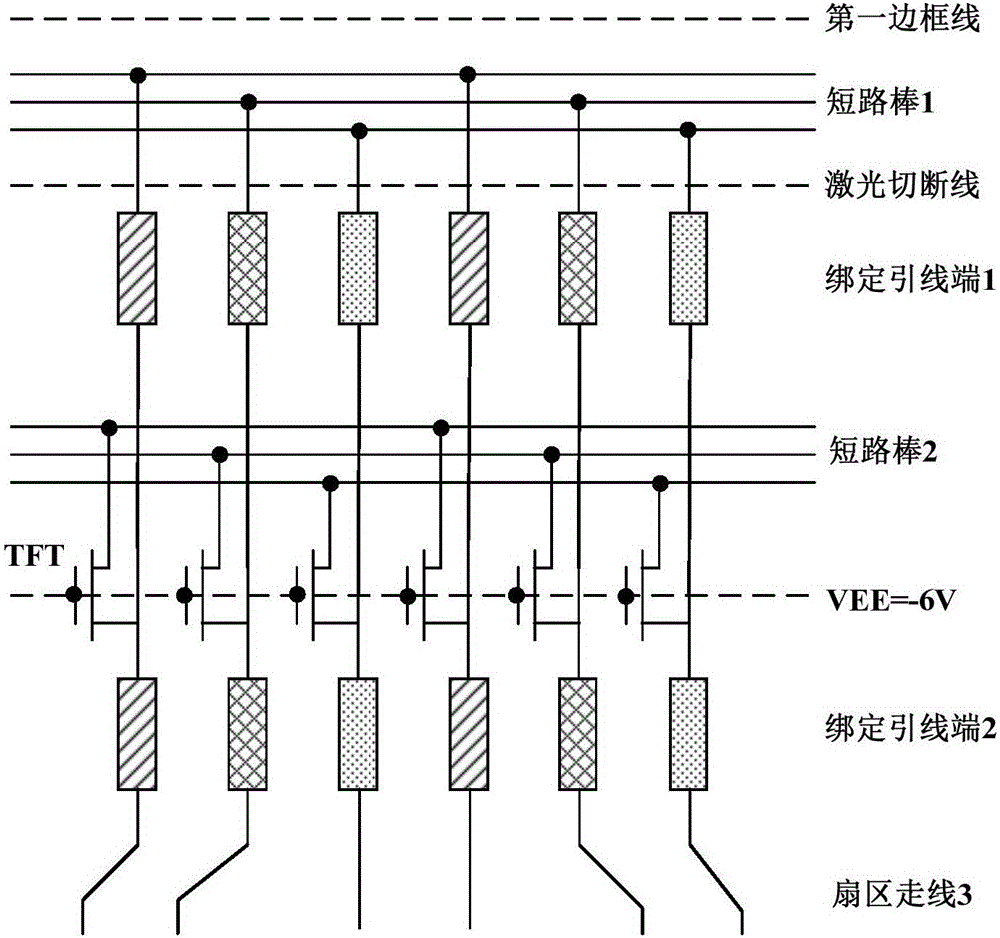

[0044] Figure 5 It is a schematic structural diagram of a display panel compatible with various frame sizes according to the second embodiment of the present invention. In this embodiment, the difference from the first embodiment lies in the location of the switch element.

[0045] As shown in the figure, the thin film transistor is still used as the switching element for illustration, and the thin film transistor is arranged in the area of the sector wiring 3 of the display panel to control the switching of the shorting bar 2 and the binding lead terminal 2 .

[0046] In this embodiment, the distance between the binding lead end 1 and the binding lead end 2 is H2, compared to the distance H1 between the binding lead end 1 and the binding lead end 2 in the first embodiment (such as figure 2 shown), H2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com