Musical instrument key column fixing structure and method

A fixed structure and key column technology, which is applied to musical instruments, wind instruments, instruments, etc., can solve the problems of increasing the production cost of musical instruments, difficult operation of workers, and affecting the use of keys, so as to achieve automatic mechanized production and reduce manual welding The effect of the workload and the firm installation of the key columns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in the form of examples, and the implementation details of the present invention will be given, but it should not be considered as a limitation of the present invention.

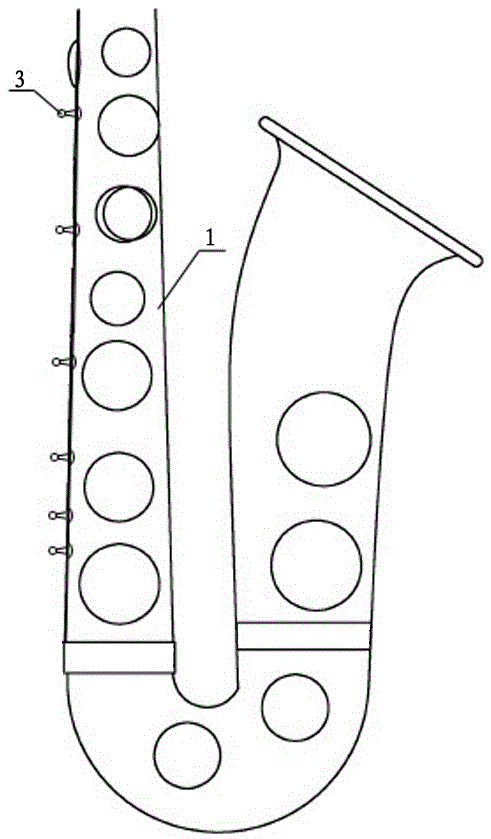

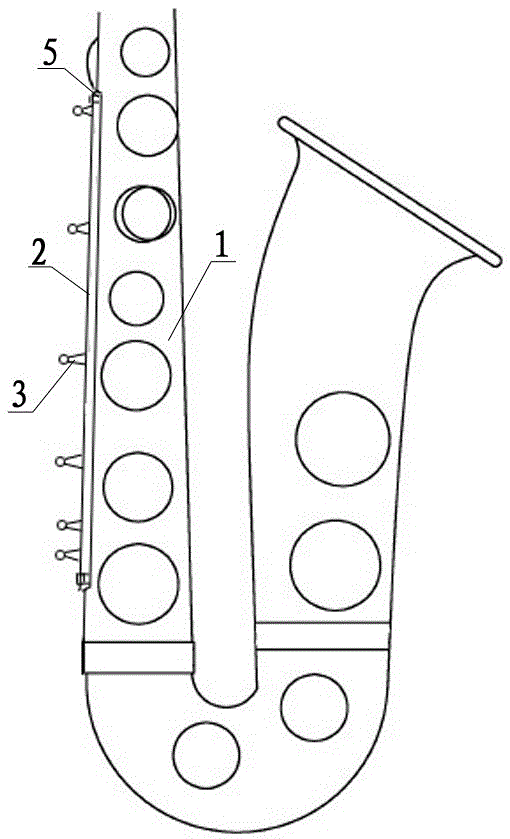

[0024] Please refer to figure 2 and image 3 As shown, the present invention provides a brass instrument piston, comprising a copper musical instrument body 1, a key column substrate 2 positioned outside the copper instrument body, a plurality of key columns 3 installed on the key column substrate, and the upper end of the key column There is a through hole 4 for installing the key rod. The bottom of the key post is provided with an internal thread hole. The key post base plate is provided with a key post fixing hole and a base plate fixing hole. The substrate fixing seat 5 is provided with an internal thread hole on the substrate fixing seat, and the key column fixing bolt passes through the key column fixing hole to fix the key column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com