Radiation-resistant power mechanical hand

A manipulator and radiation-resistant technology, applied in nuclear engineering, protected chambers, etc., can solve problems such as lack of radiation resistance, small load, and lack of real-time monitoring, so as to reduce direct or indirect contact with radioactive waste, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

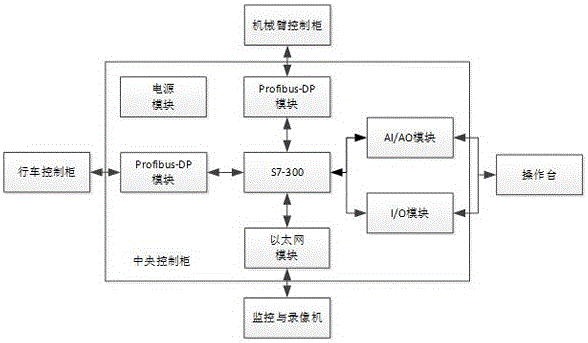

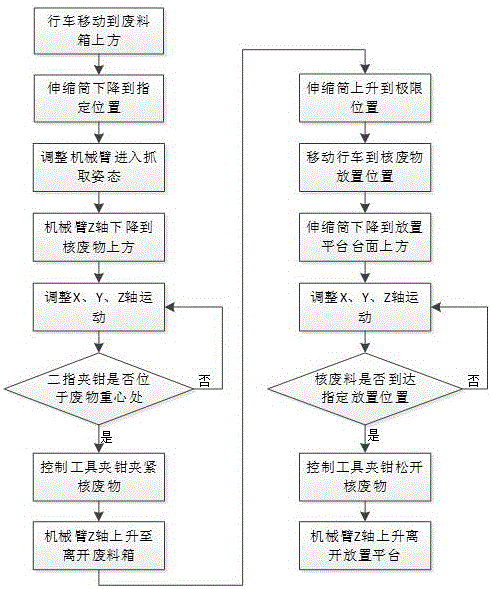

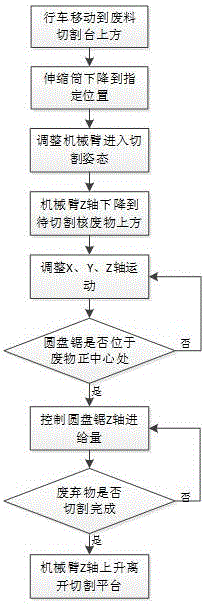

[0030] Such as figure 1 As shown, a radiation-resistant power manipulator includes a control room, a shielding wall and a hot room, and a control system is set in the control room. The control system includes at least a central control cabinet, a driving control cabinet, a mechanical arm control cabinet, an operating console, box, a penetrating piece is arranged on the shielding wall, and an operation execution system is arranged in the hot chamber. The operation execution system at least includes a crane, a telescopic cylinder, monitoring equipment, and a tool shelf. The crane includes a mechanical arm, a cart, and a trolley; the control The control lines of the central control cabinet, driving control cabinet, and manipulator control cabinet in the room are connected to the driving, monitoring equipment and tool shelves in the thermal chamber through the penetrations on the shielding wall.

[0031] The control room is also provided with an operation console and a hand box. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com