A stacked parallel mold

A mold and base mold technology, applied in the field of stacked parallel molds, can solve the problems of time-consuming and laborious replacement and installation of parallel molds, affecting cable production efficiency, and increasing the manufacturing cost of parallel molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

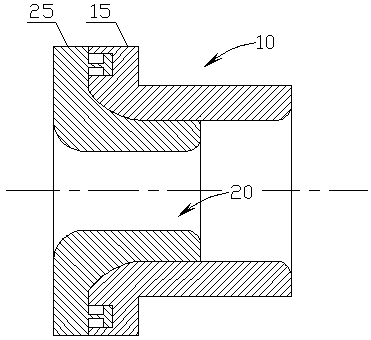

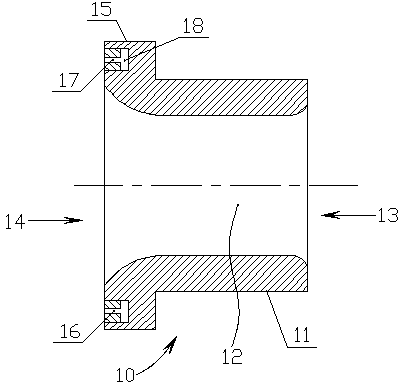

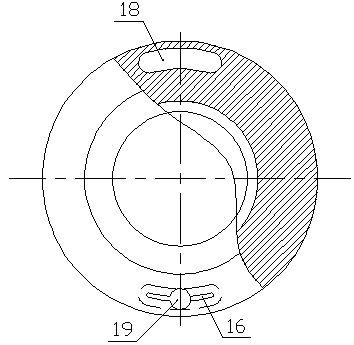

[0016] see figure 1 - Figure 6 , a stacked paralleling mold of the present invention, comprising a base mold 10, the base mold 10 has a cylindrical base mold body 11, the base mold body 11 has a base mold paralleling channel 12, and one of the base mold paralleling channels 12 One side has a basic mold paralleling line inlet 13, and the other side has a basic mold paralleling line outlet 14, and the basic mold body 11 located on one side of the basic mold paralleling line outlet 14 has a base mold peripheral vertically protruding outside the basic mold body. Along 15, a sub-mold 20 is also included. The sub-mold 20 has a cylindrical sub-mold body 21, and the sub-mold body 21 has a sub-mold paralleling channel 22, and one side of the sub-mold paralleling channel 22 has a sub-mold paralleling inlet. 23. The other side has a sub-mold doubling outlet 24, and the sub-mold body 21 on one side of the sub-mold doubling outlet 24 has a sub-mold peripheral edge 25 extending vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com