A kind of probe structure used in wat detection machine

A detection machine and probe technology, applied in the field of probe structure, can solve the problems of low motion efficiency, complex assembly, complex maintenance, etc., and achieve the effects of small moving load, avoiding complex assembly, and improving contact accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

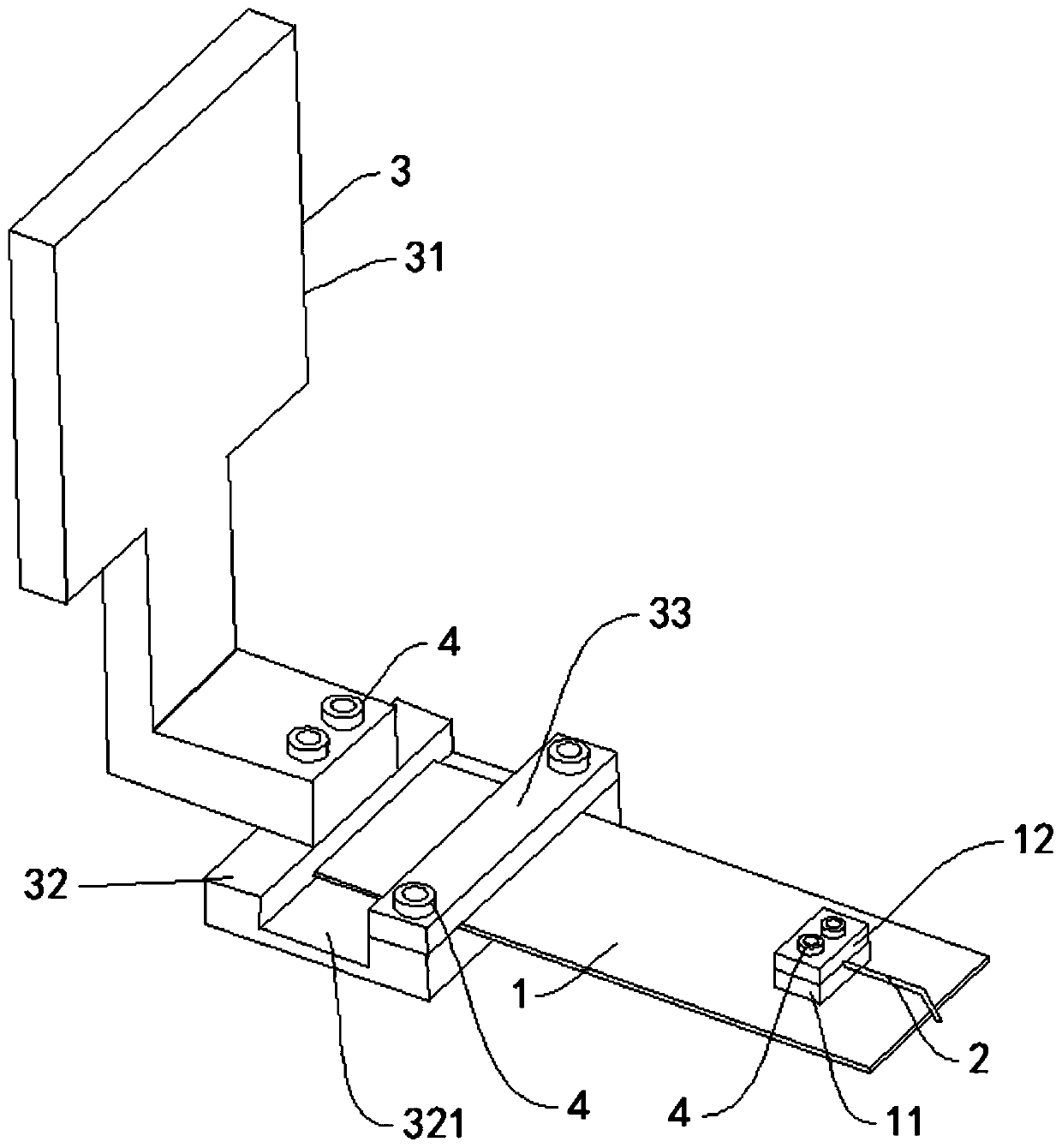

[0027] Such as figure 1 As shown, a probe structure for a WAT detector includes a piezoelectric ceramic bending actuation piece 1, one end of the piezoelectric ceramic bending actuation piece 1 is provided with a probe 2, and the other end is arranged on a fixed bracket 3 ; The positive and negative connections of the piezoelectric ceramic bending actuator piece 1 are electrically connected to the power supply through wires, and the power supply is electrically connected to the controller.

[0028] The fixed bracket 3 includes a fixed plate 31 and a connecting plate 32; one end of the connecting plate 32 is connected to the fixed plate 31, and the other end cooperates with the first fixed cover plate 33 above it t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com