Square steel shell battery and module for assembling battery system

A technology of synthesizing batteries and square steel, applied in battery pack parts, secondary batteries, alkaline batteries, etc., can solve problems such as battery consistency difference, increase in total battery weight, seal failure, etc., to increase its own strength, The effect of improving the uneven reaction and preventing the blockage of the gas path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

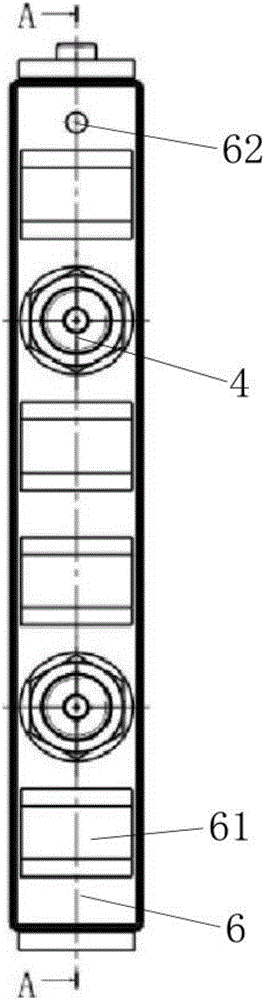

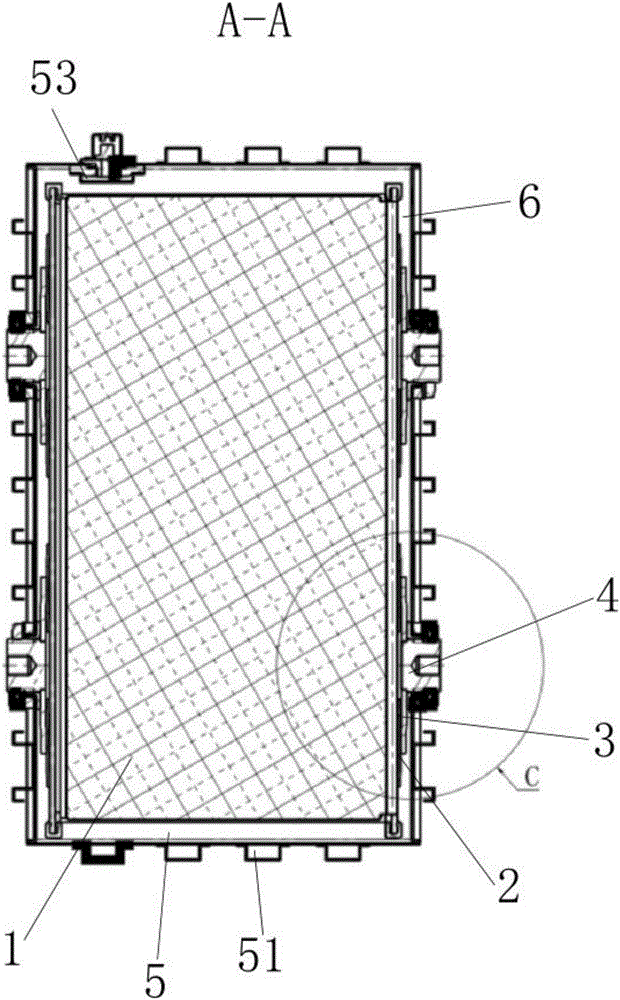

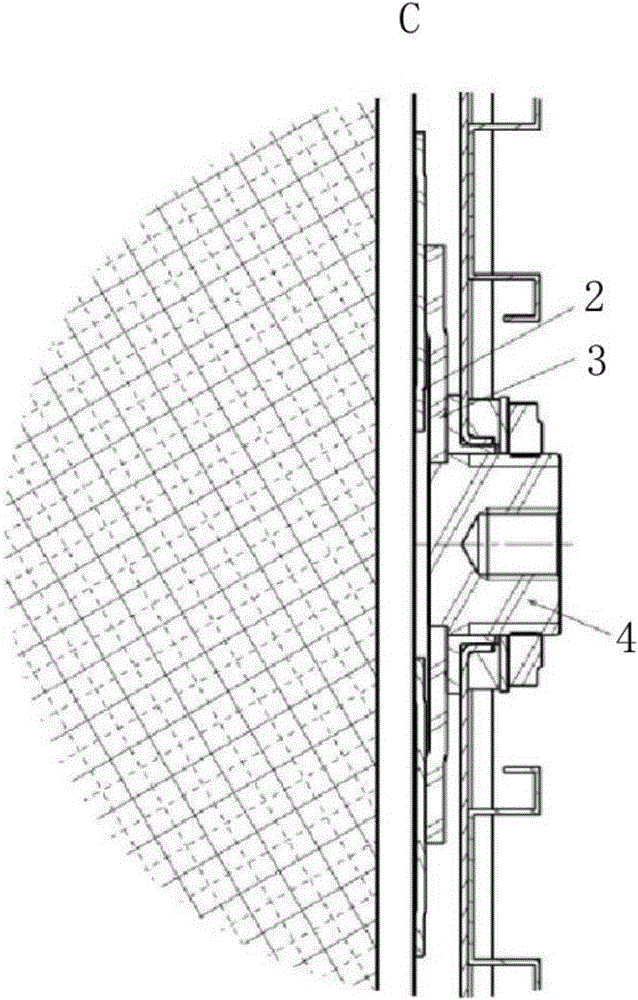

[0037] refer to Figure 1-Figure 18 , the present invention is a square steel shell battery and its module assembled into a battery system, including a battery cell electrode group 1, a first-level internal connection guide plate 2, a second-level internal connection guide plate 3, a lead-out terminal 4, and a battery case 5. The battery cover 6, the side bracket 7 and the grid 8. The battery cell electrode group 1 is arranged inside the battery case 5, and the first-level internal connection deflectors 2 are arranged on both sides of the battery cell electrode group 1, and the first-level internal connection The deflector 2 is provided with a secondary internal connection deflector 3, and the middle part of the secondary internal connection deflector 3 is provided with a central hole, and a lead end 4 is welded at the central hole; the battery case 5 is provided with a battery on both sides of the cover. A cover 6; a grid 8 is arranged between the side brackets 7; the cell po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com