Sealing device for button cells

A technology of sealing device and button battery, which is applied in the direction of manufacturing primary battery equipment, primary batteries, circuits, etc., can solve the problems of reducing the work efficiency of employees, reducing the economic benefits of enterprises, and high human resource costs, so as to achieve low human resource costs and high production efficiency. The effect of high efficiency and less workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

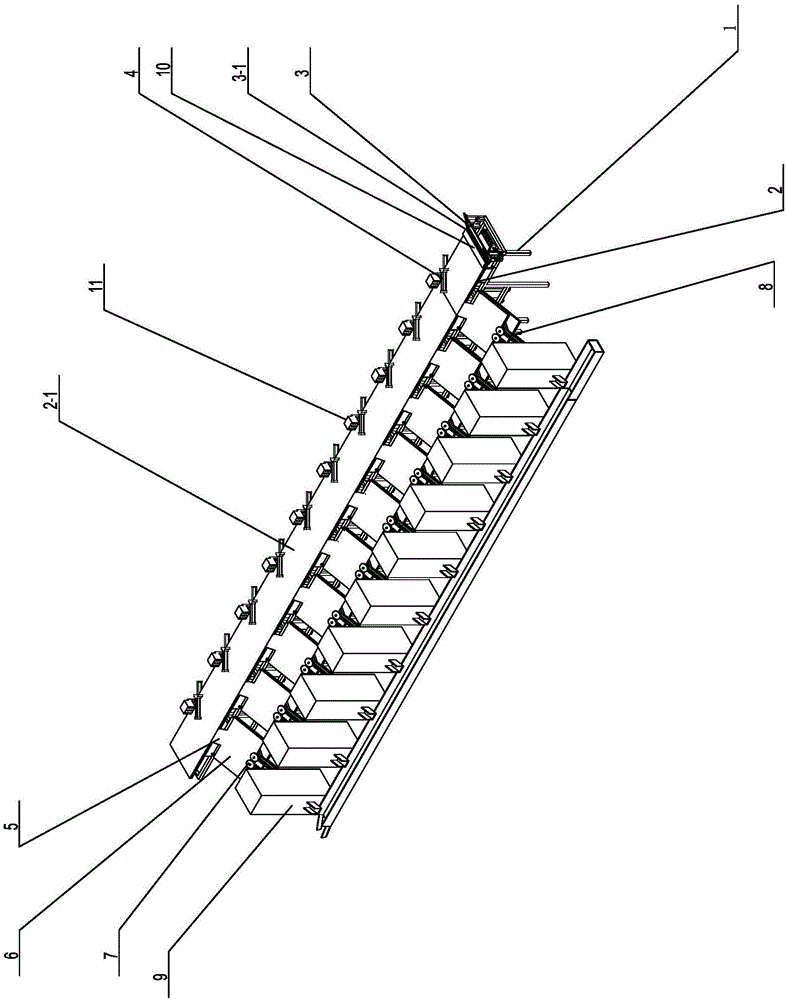

[0018] like figure 1 A specific embodiment of the present invention is proposed as shown, the sealing device for the button battery includes a frame 1, and a conveyor belt 2 is horizontally arranged above the frame 1, and the left and right sides of the conveyor belt 2 are arranged in this embodiment. Aluminum strips are provided for positioning and protection, and the transmission belt 2 is driven by the wheel motor for transmission. The top of the transmission belt 2 is provided with a protective cover 2-1 for preventing the battery from falling. In order to facilitate the viewing of the battery transportation status, this The embodiment sets the protective cover plate 2-1 as transparent glass, and the front end of the conveyor belt 2 is inclined to be provided with a stripping pallet 3, the two sides of the stripping pallet 3 are provided with protection, and the front end is provided with a protrusion, so The protrusions are used to wipe the battery on the magnetic plate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com