Automatic thermal management method for battery modules

A battery module, thermal management technology, applied in the direction of secondary battery, electrochemical generator, secondary battery repair/maintenance, etc., can solve the problem of unable to maintain normal work, leakage, pipeline falling off, etc., to achieve the best performance and longevity, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

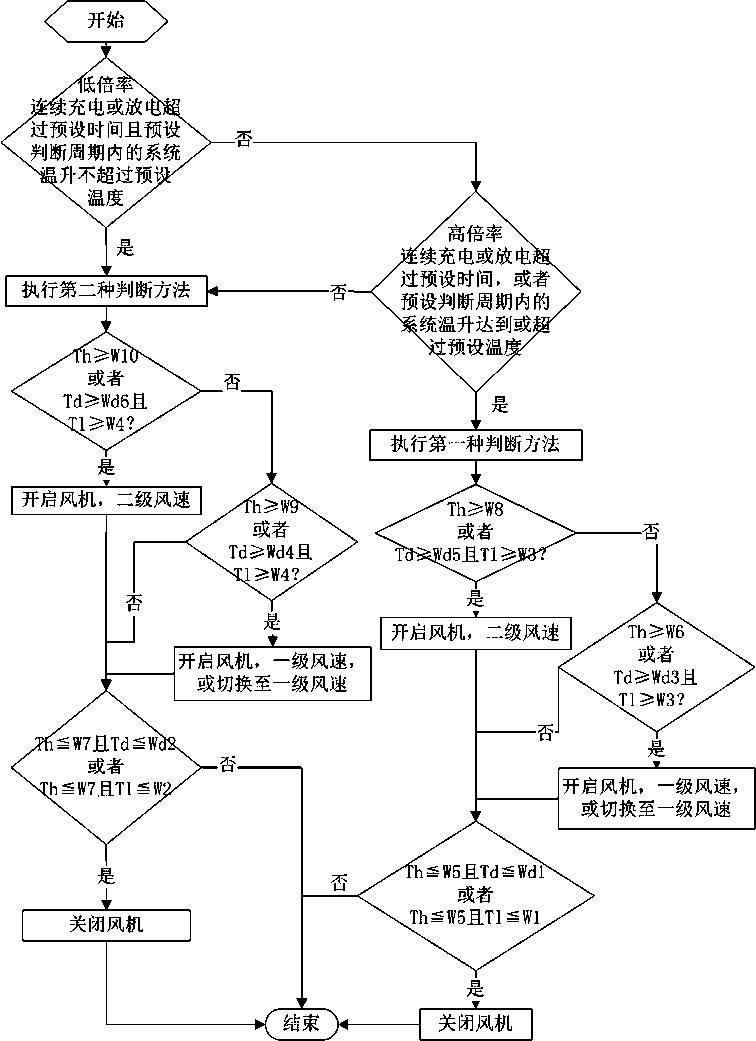

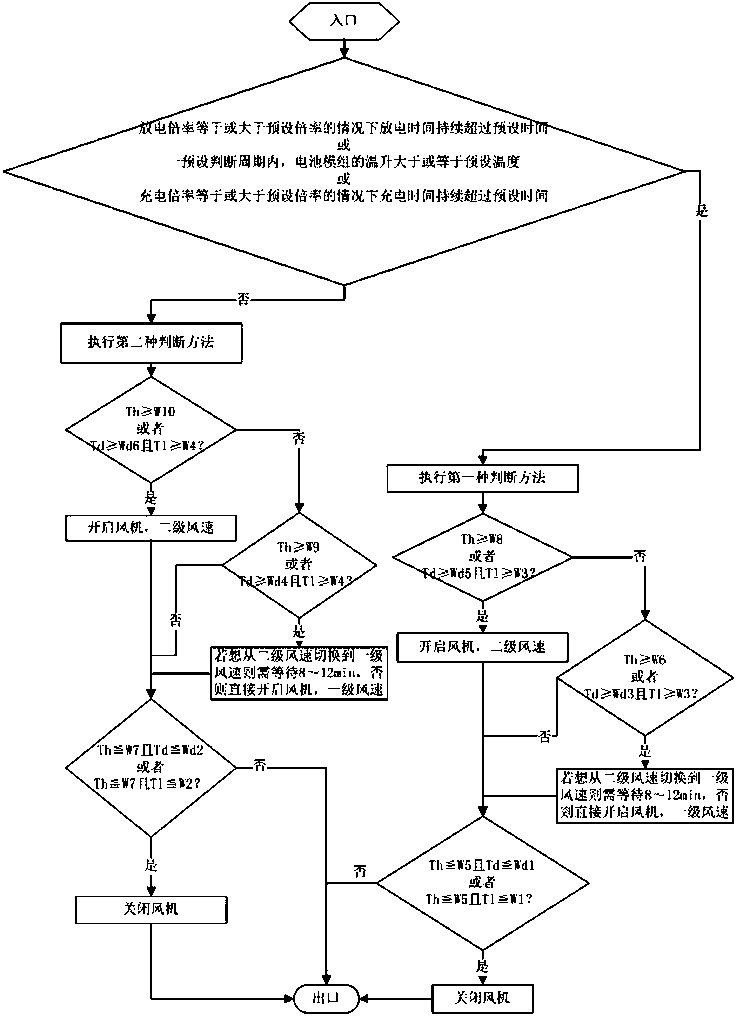

[0020] The battery module automatic thermal management method of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0021] Such as figure 1 As shown, in a preferred embodiment, the battery module automatic thermal management method of the present invention is used in the management system of the battery module, and is mainly used to control the fan of the heat dissipation system according to the current charging and discharging rate, temperature and other working conditions of the battery module. Take timely control. Among them, the battery module has built-in multiple temperature sensors, which are used to detect the temperature of multiple points (generally evenly distributed points) or each battery cell in the battery module.

[0022] For the convenience of description, first, define the current highest battery temperature of the battery module as Th, the current lowest battery temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com