Experimental heating apparatus for solid sample

A technology for heating devices and samples, which is applied in the direction of measuring devices, laboratory appliances, heating or cooling equipment, etc., can solve the problems of difficult to meet the requirements, unfavorable rapid experiments, high heating power, etc., to save experimental time and study the heating rate and cooling rate range expansion, the effect of controllable heating rate and cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

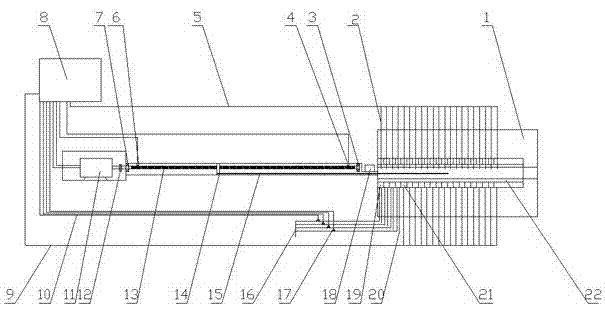

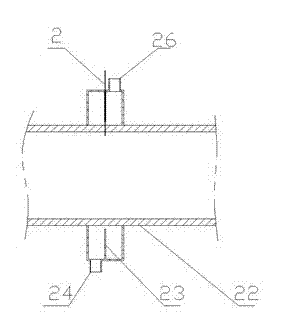

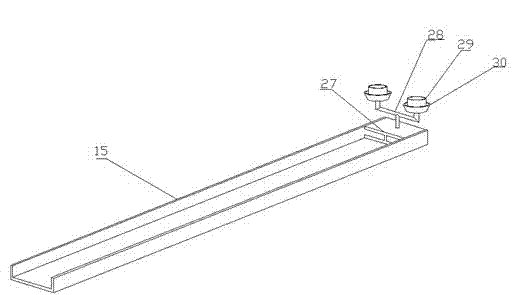

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] figure 1 It is a schematic diagram of the structure of the solid sample experimental heating device, figure 2 is a schematic diagram of the structure of the cooling assembly, image 3 It is a schematic diagram of the structure of brackets, trays and crucibles installed on the injection tank, Figure 4 A schematic cross-sectional view of the bracket, tray and crucible installed on the injection tank, as shown in the figure. The solid sample experiment heating device includes a heater insulation shell 1, a controller 8, a sampling tank 15, a heater 21, a cooler 19, a thermocouple I 2, a sealing cover (not shown in the figure), and driving the sampling tank 15 to advance or The driving mechanism of the sampling tank that retreats, the micro-powder feeder 18 that adds samples to the sampling tank 15, the bracket 27, the tray 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com