A method for optimizing the layout of heat conduction plates in battery modules

A battery module and optimization method technology, applied in the direction of secondary batteries, electrochemical generators, circuits, etc., can solve the problem of increasing the heat dissipation capacity of the battery module, and achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

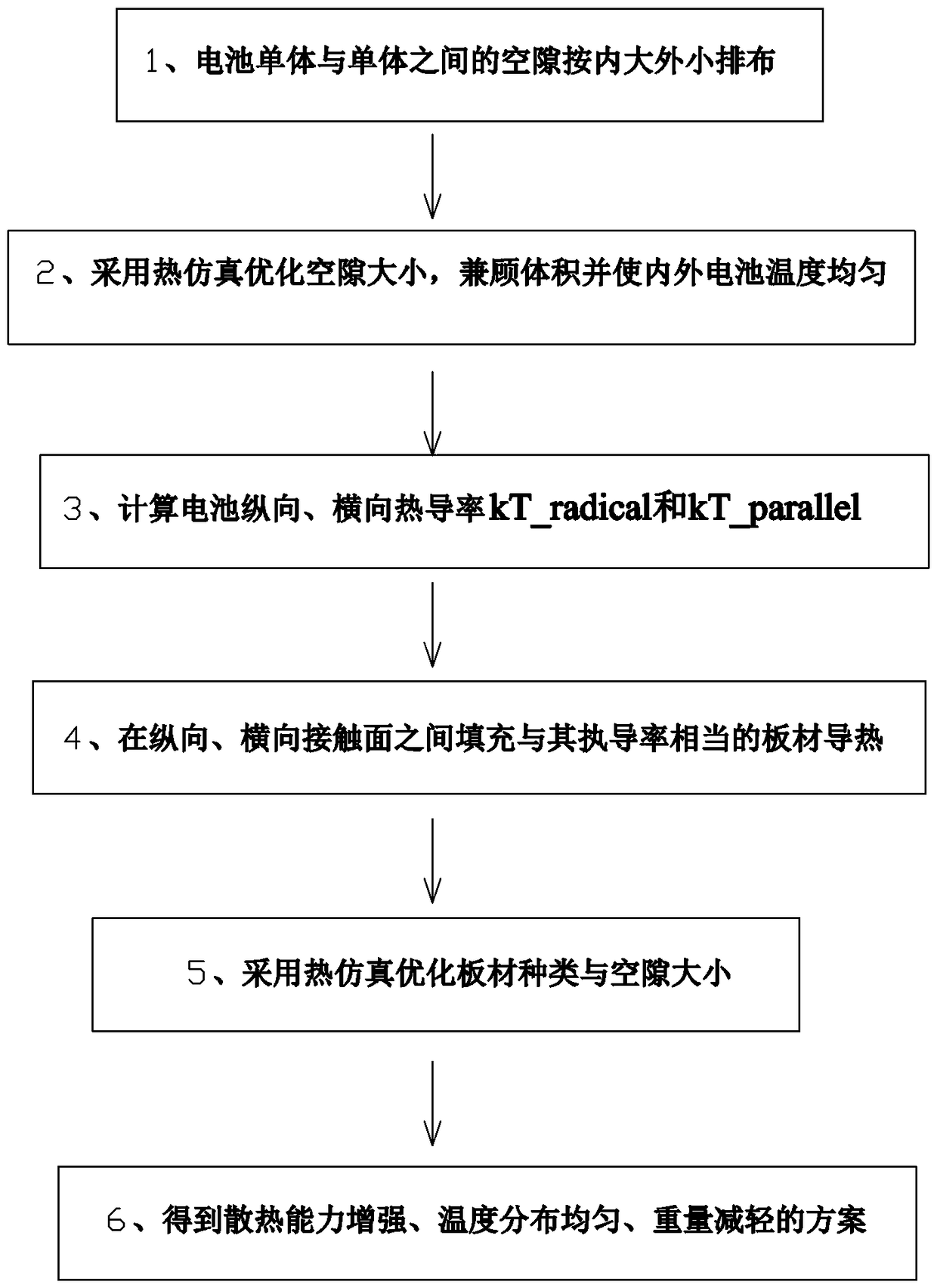

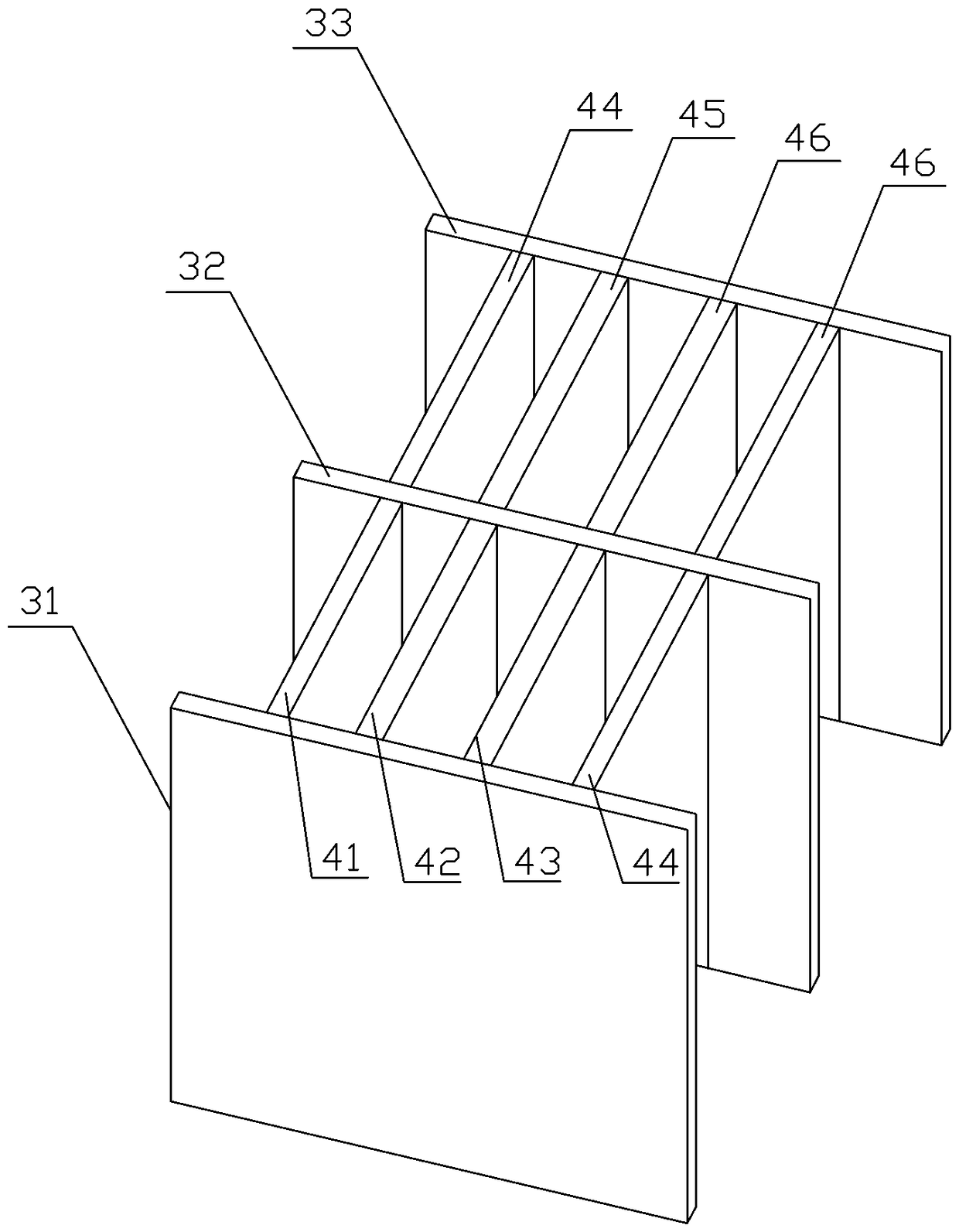

[0025] Such as figure 1 , figure 2 As shown, a method for optimizing the arrangement of heat conducting plates of a battery module, the method for optimizing the arrangement includes the following specific steps:

[0026] Step 1: The battery module consists of 10 battery cells arranged in a 2*5 arrangement. A certain gap is left between the battery cells, and the gap gradually increases from the outside of the module to the center of the module.

[0027] Step 2: Based on the current size and usage time of the battery under operating conditions, build a thermal simulation with the gap between the battery cells and the gap between the battery cells and the module box in step 1 as the changing parameters Model; 10 gap size schemes, according to the thermal simulation calculation results, the average temperature of each battery cell is T_ avg , calculate 10 cells T_ avg According to the calculation results, further adjust the gap size setting of 10 schemes, increase the gap si...

Embodiment 2

[0032] Such as figure 1 , figure 2 As shown, a method for optimizing the arrangement of heat conducting plates of a battery module, the method for optimizing the arrangement includes the following specific steps:

[0033] Step 1: The battery module consists of 10 battery cells arranged in a 2*5 arrangement. A certain gap is left between the battery cells, and the gap gradually increases from the outside of the module to the center of the module.

[0034]Step 2: Based on the current size and usage time of the battery under operating conditions, build a thermal simulation with the gap between the battery cells and the gap between the battery cells and the module box in step 1 as the changing parameters model; there are 10 gap size schemes, and according to the thermal simulation calculation results, the average temperature of each single battery is T_ avg , calculate 10 cells T_ avg According to the calculation results, further adjust the gap size setting of 10 schemes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com