Power maintenance annular machine applied to severe weather and application method of power maintenance annular machine

A bad weather and electric power technology, applied to the installation of electrical components, cables, overhead lines/cable equipment, etc., can solve problems such as hindering deicing operations, cumbersome deicing devices, and deicing devices increasing the load of the power grid, etc., to achieve reduction Small secondary damage, good deicing effect, saving manpower and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

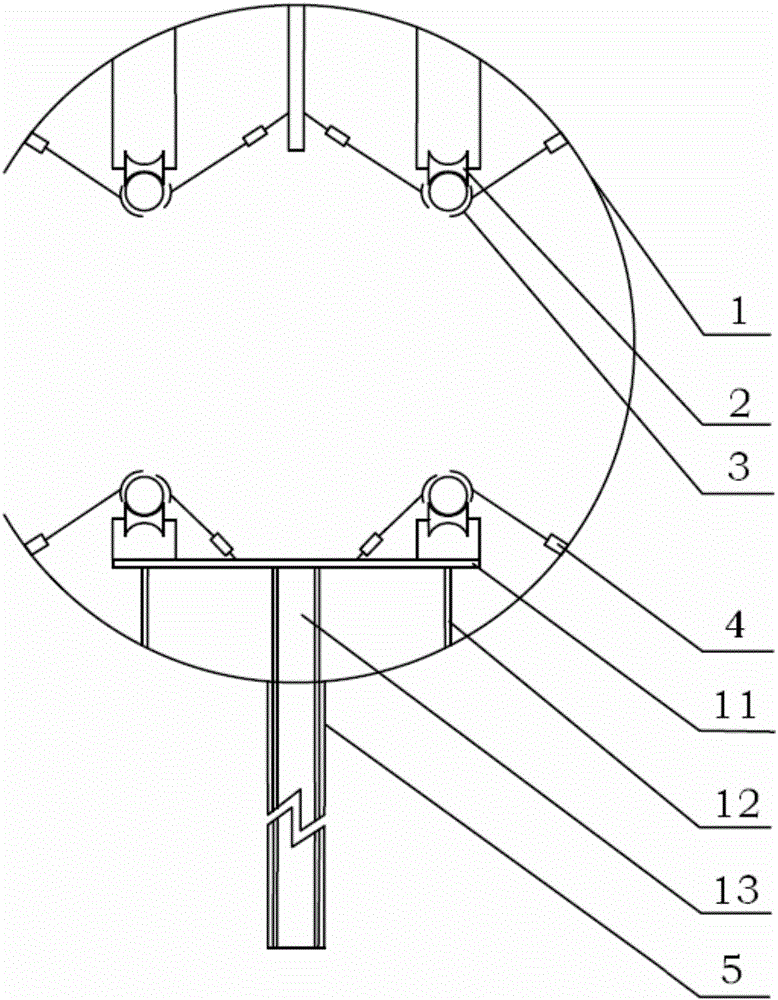

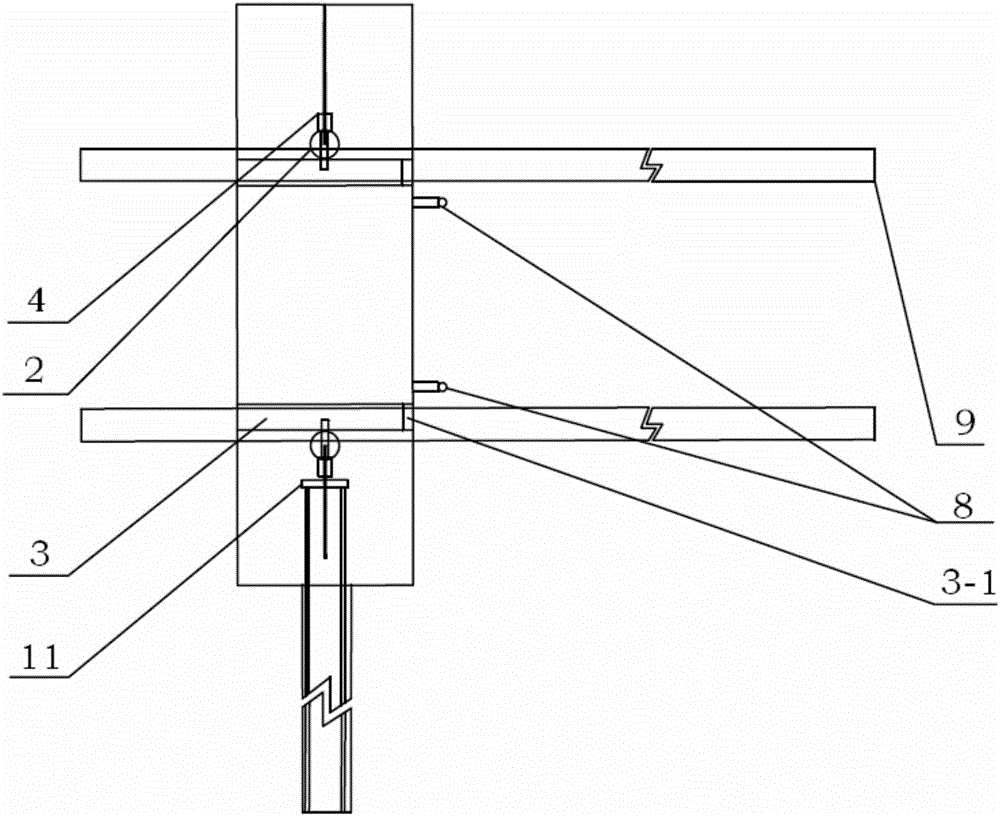

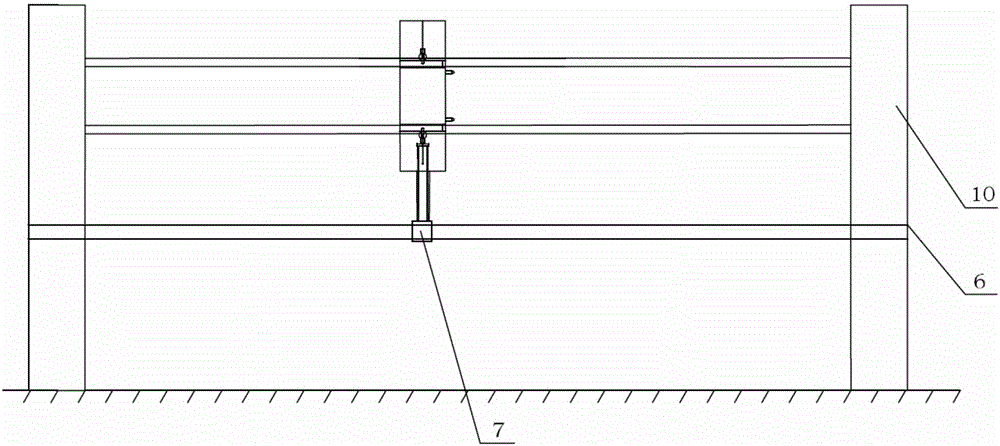

[0038] A ring machine for electric power maintenance used in bad weather, including a frame with openings for placing wires into the frame, four rollers inside the frame, the middle surface of the rollers is concave at both ends of the rollers , so that the roller can be placed on the wire to roll and drive the device to walk and maintain a certain stability. The frame on both sides of the roller is provided with arc hoops, which are connected to the frame through the cylinder, and the sides of the arc hoop are blade edges. . Dispose the wire from the opening to the roller in the frame, control the cylinder to clamp the arc hoop on the wire, move the device, and use the edge of the arc hoop to perform deicing operations.

[0039] The frame is a circular frame, and the cross-section of the frame is circular.

[0040] The frame is aluminum frame. The device can complete the deicing operation with a relatively light weight, and at the same time can ensure a certain strength to ...

Embodiment 2

[0042] A ring machine for power maintenance used in severe weather, its structure is the same as that described in Embodiment 1, the difference is that the roller is provided with a heating wire. The heating wire can initially melt the ice and snow on the wires in contact with the rollers, assisting in deicing.

Embodiment 3

[0044] A ring machine for power maintenance used in bad weather, its structure is the same as that described in Embodiment 1, the difference is that two adjacent rollers are connected to the horizontal plate, and the two ends of the horizontal plate are provided with limit columns, and the limit columns It is connected with the frame, and the middle part of the horizontal plate is provided with a threaded rod. Because the rollers have a certain bending arc, in order to put the four wires in smoothly, before putting the wires in, the horizontal plate moves toward the frame through the helical movement of the threaded rod and the limit function of the limit post, thereby driving the two rollers. The column also moves towards the direction of the frame, and the distance between it and another roller increases. After putting in the wire, rotate the threaded rod in the opposite direction and push the horizontal plate to move in the opposite direction, so that the concave surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com