Brush positioning method for single-wave winding permanent magnet DC motor based on the second pitch

A single-wave winding and positioning method technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problem of brush position changes, differences, and inability to clearly express the relationship between magnetic steel stators, brushes and coil components, etc. problem, to achieve the effect of clear thinking and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

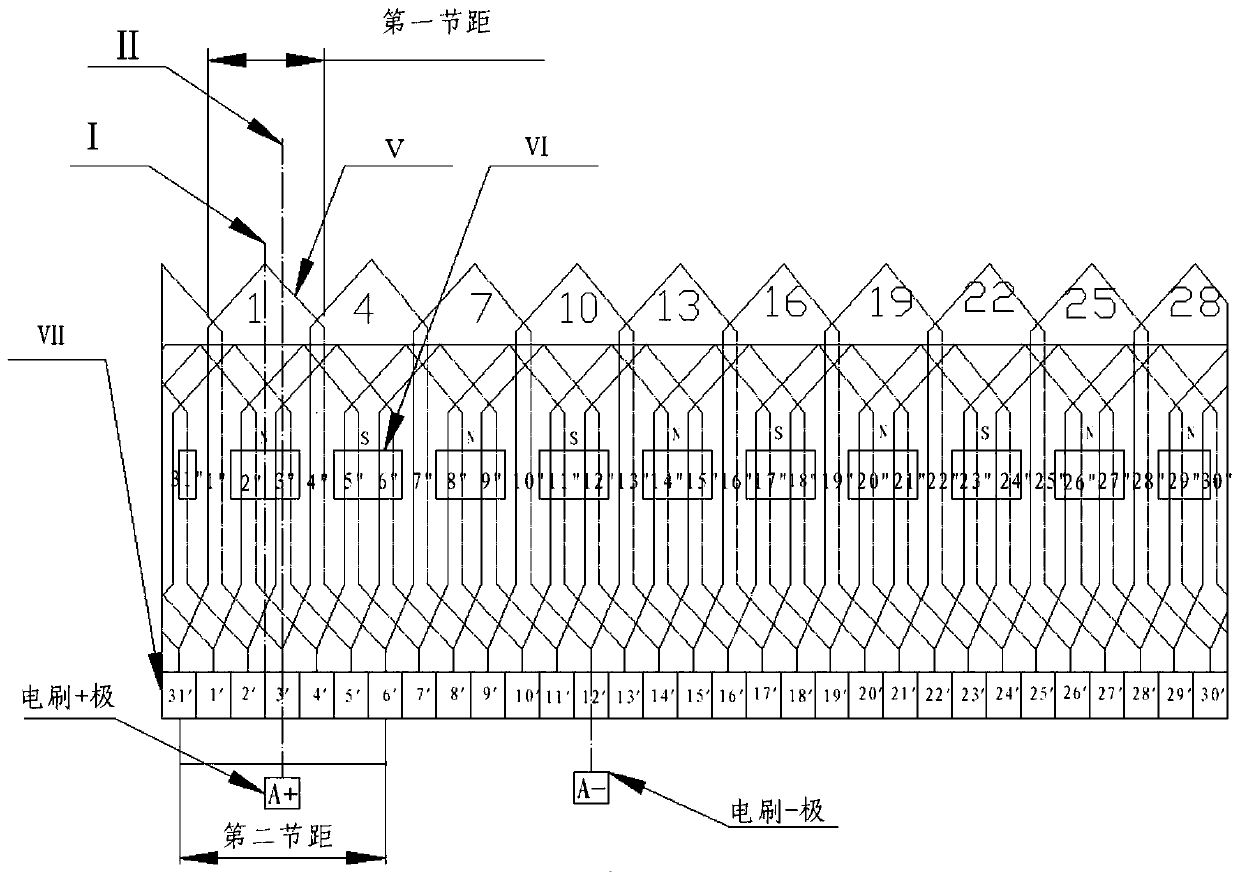

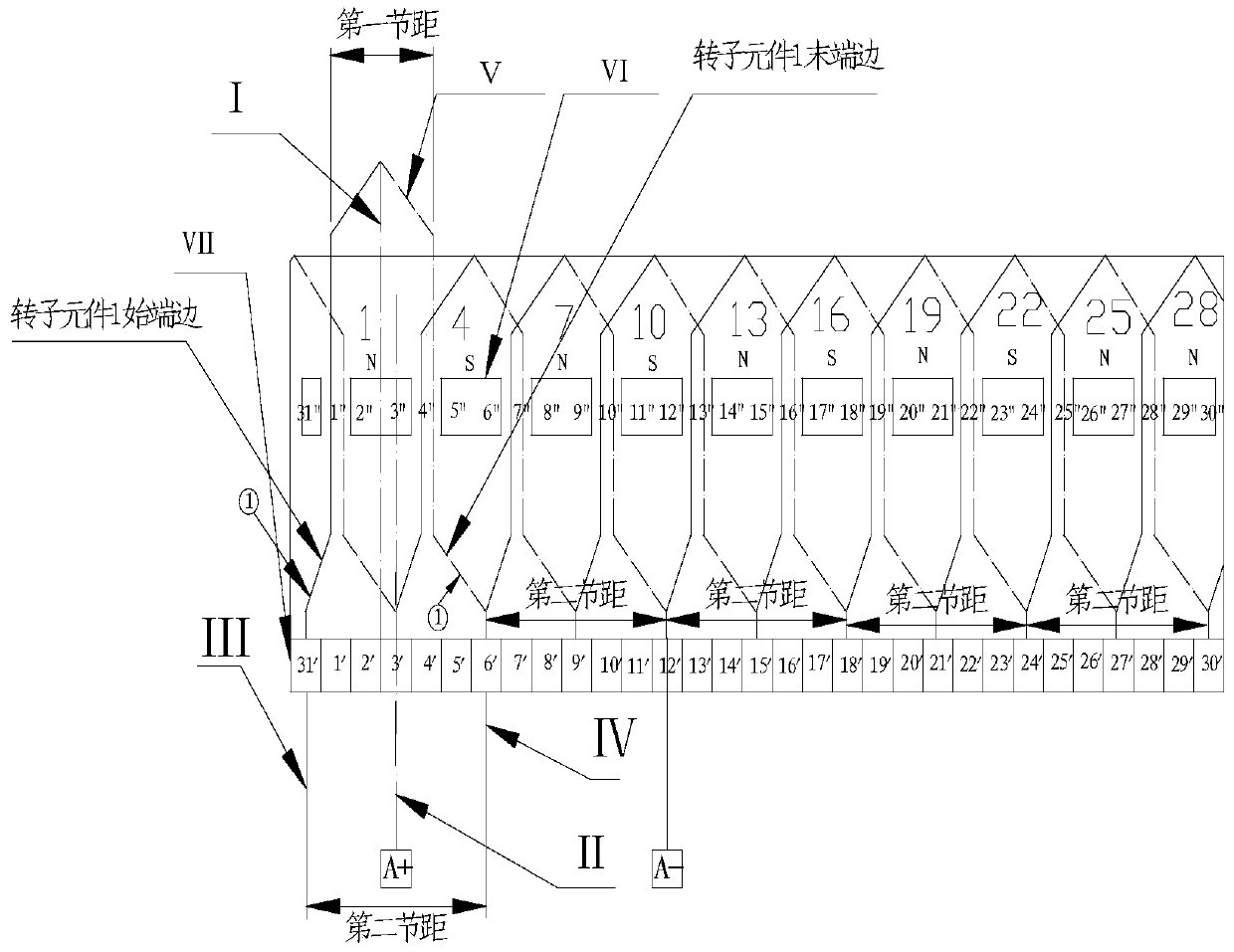

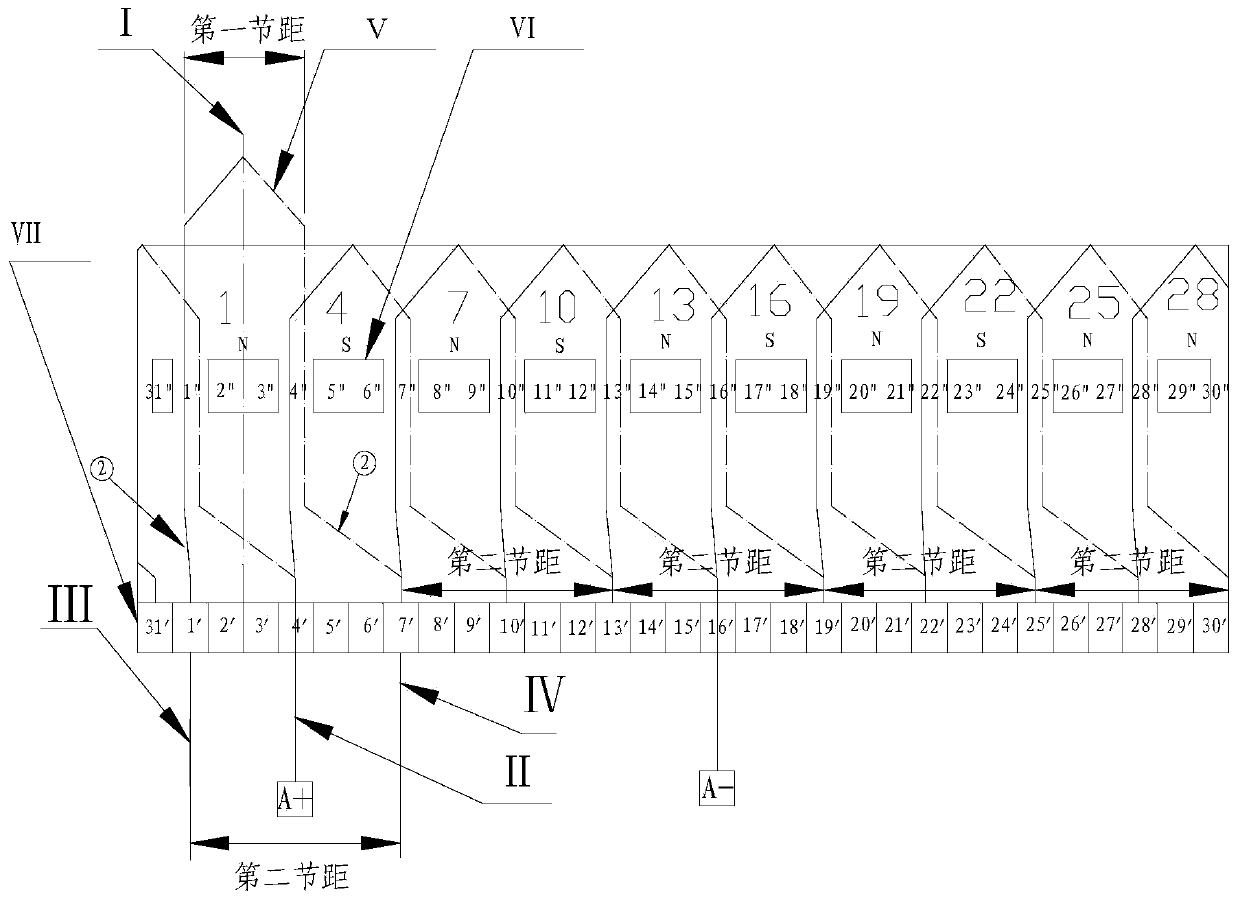

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings. First, the symbolic representations in each figure will be explained. figure 1 , figure 2 and image 3 Ⅴ in the figure represents the rotor element, Ⅵ represents the stator magnet, and Ⅶ represents the commutator segment.

[0017] A method for positioning a brush of a permanent magnet DC motor with a single-wave winding based on a second pitch, the method comprising the following steps:

[0018] Step 1: Select the moment when the potential of the rotor element of the single-wave winding permanent magnet DC motor is the largest and the current is zero, and establish the time expansion diagram of the stator magnet, rotor element and commutator at this time, and determine the rotor element in the time expansion diagram For all the rotor elements whose axis coincides with the axis of each stator magnetic steel, the start end and end edge of each rotor element i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com