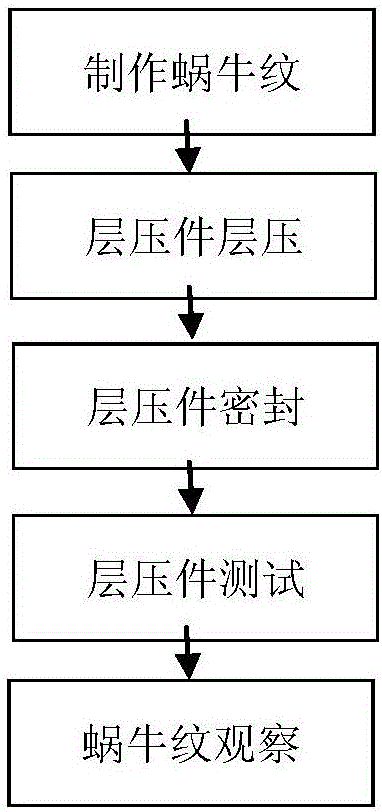

Solar battery module snail grain testing device and method

A solar cell and testing device technology, applied in the monitoring of electrical components, photovoltaic systems, photovoltaic power generation, etc., can solve the problems of production, research, teaching inconvenience, long test cycle, etc., achieve reasonable test cycle, shorten test cycle, and evaluate accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

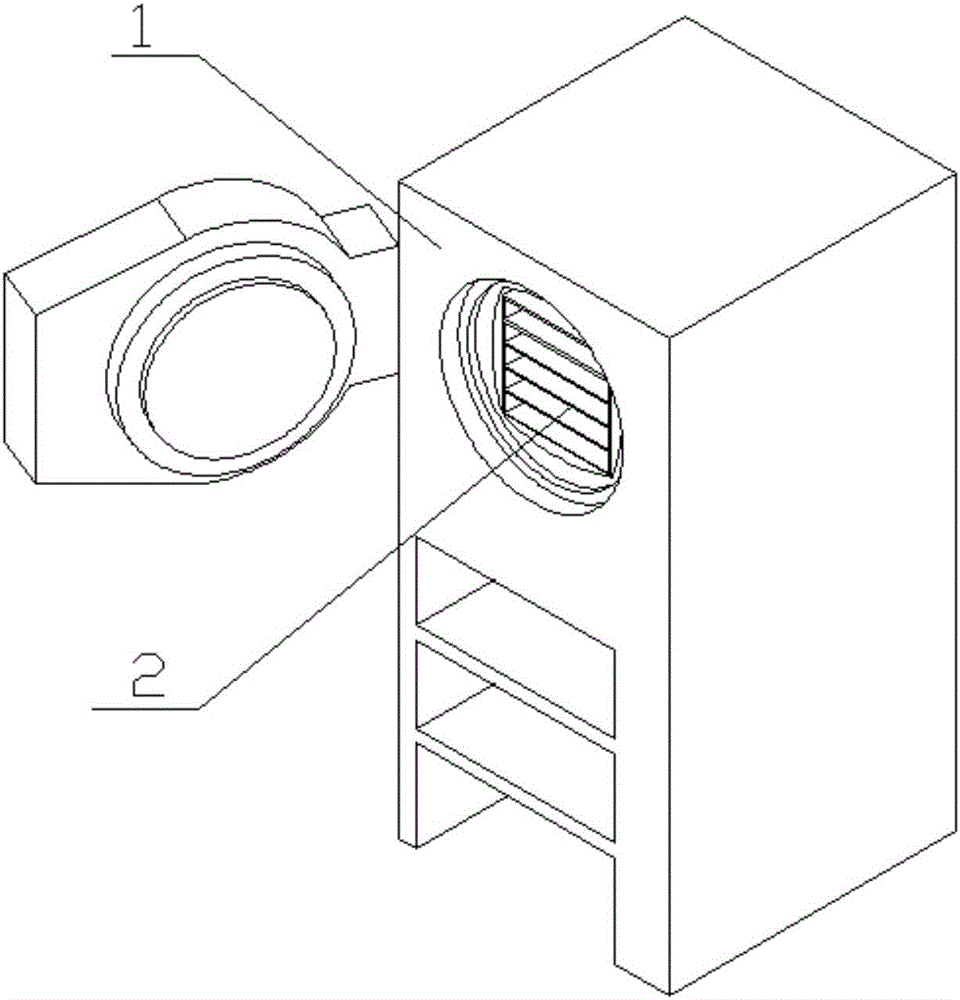

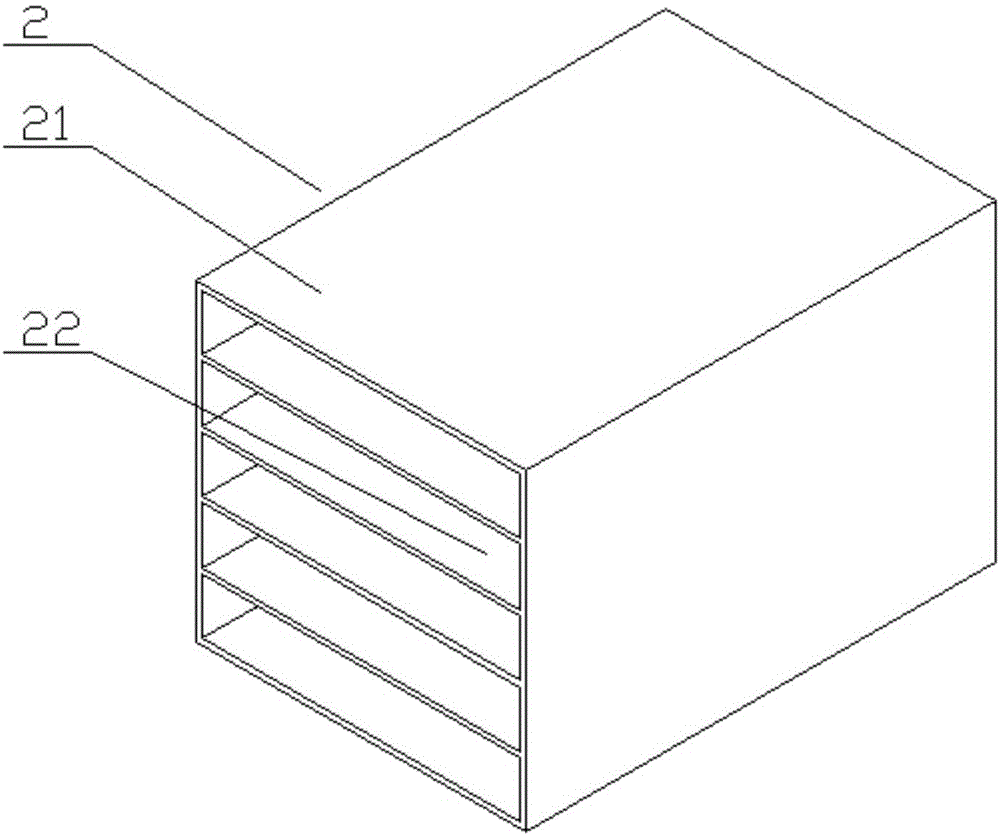

[0038] A kind of snail pattern test device of solar cell module, such as figure 1 As shown, it includes a high-voltage accelerated aging test test box 1, wherein the test device also includes a test piece support 2 placed in the test box 1 for carrying multiple test pieces, such as figure 2 As shown, it includes a hollow cuboid support body 21 with a front opening and at least one partition 22 arranged horizontally inside the support body 21 .

[0039] Further, four partitions 22 are provided.

[0040] Further, the bracket 2 is made of stainless steel.

[0041] Further, the bracket 2 can withstand a temperature of -100°C to 200°C.

[0042] Further, the support 2 can withstand 0-100% RH humidity.

[0043] Further, the support 2 can withstand 1-3 atmospheres.

[0044] After the support 2 is placed in the experiment box 1, the experiment box can only place one piece of test piece at a time, but now it can hold multiple test pieces, which greatly improves the experiment effic...

Embodiment 2

[0062] Only the differences from Embodiment 1 will be described below.

[0063] Select 80 normal cells with no cracks, tap all the cells with a pencil until the cells are obviously cracked, and make 10 cracked laminates. The laminates made of 10 cracked batteries were selected from the test conditions and observation period of the present invention (temperature: 120°C; humidity: 100% RH; air pressure: 2 atmospheres; cycle: 24h), and 10 normal comparison laminates were selected from other inventions Test conditions and test cycle (temperature: 85°C; humidity: 85% RH; light intensity: 1000W / M2; cycle: 1000h). Specifically as shown in Table 2:

[0064] Table 2

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com