A compensating driving device and its realization method

A technology of a driving device and an implementation method, which is applied in the direction of lighting devices, light sources, electrical components, etc., can solve the problem that the temperature coefficient compensation accuracy cannot fully meet the performance requirements of LED drivers, etc., and achieves the improvement of load adjustment rate and temperature coefficient and low cost. , Improve the effect of load regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

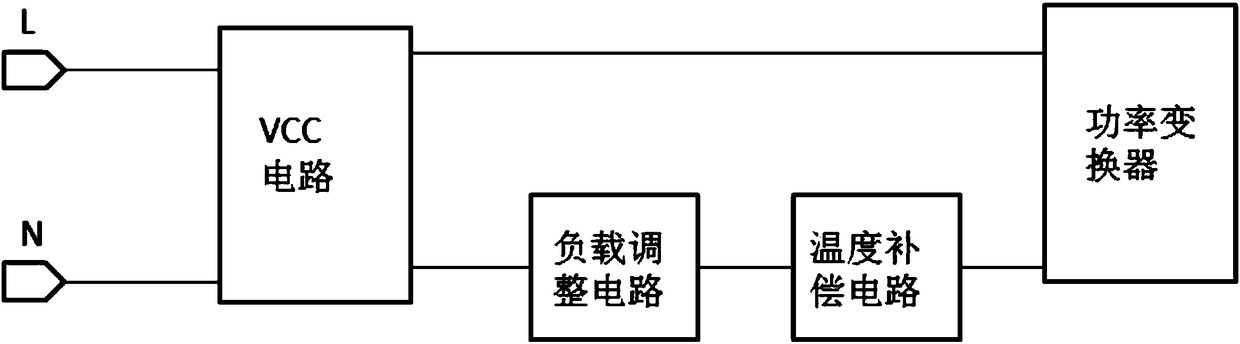

[0031] Such as Figure 1~2 As shown, a compensating drive device includes a VCC circuit that converts an input AC signal into a DC signal and simultaneously starts and controls the device; a compensation circuit that adjusts load regulation and temperature coefficient; a power converter including a chip control module ; Wherein, the power converter is connected to the VCC circuit and the compensation circuit respectively.

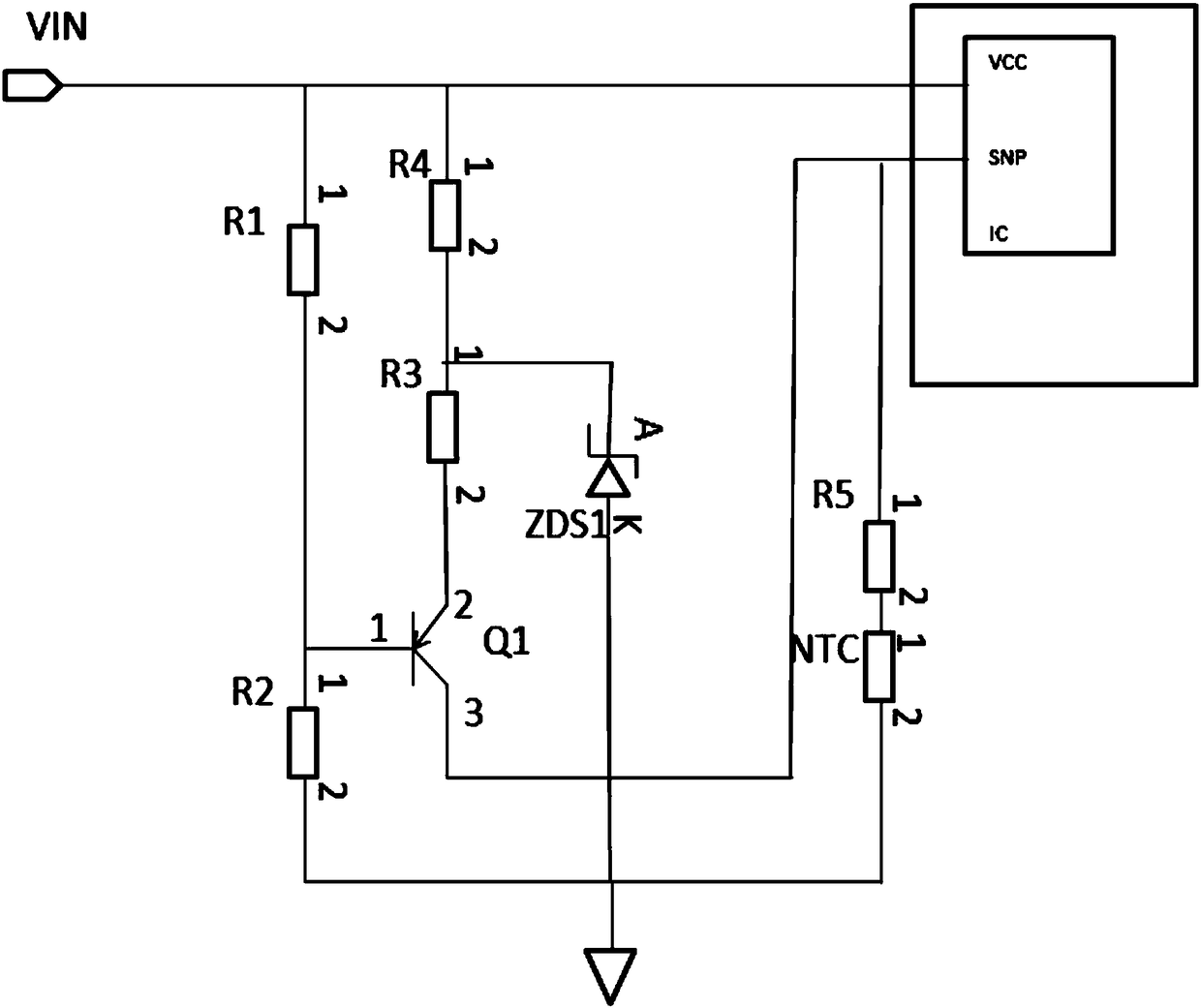

[0032] The compensation circuit in this embodiment includes an amplification circuit and a shunt circuit. Such as figure 2 As shown, the amplifying circuit includes a first resistor R1, a second resistor R2, a third resistor R3, a fourth resistor R4, a first voltage regulator transistor ZDS1 and a first triode Q1; wherein, the first end of the first resistor R1 and The second circuit is connected, the second end of the first resistor R1 is connected with the first end of the second resistor R2 and the base of the first triode Q1, the second end of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com