Circuit for controlling and identifying a plasma torch

A plasma torch and electronic circuit board technology, applied in the field of ion torch control and identification circuits, can solve problems such as data reading and management difficulties, equipment shutdown, and plasma torch wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

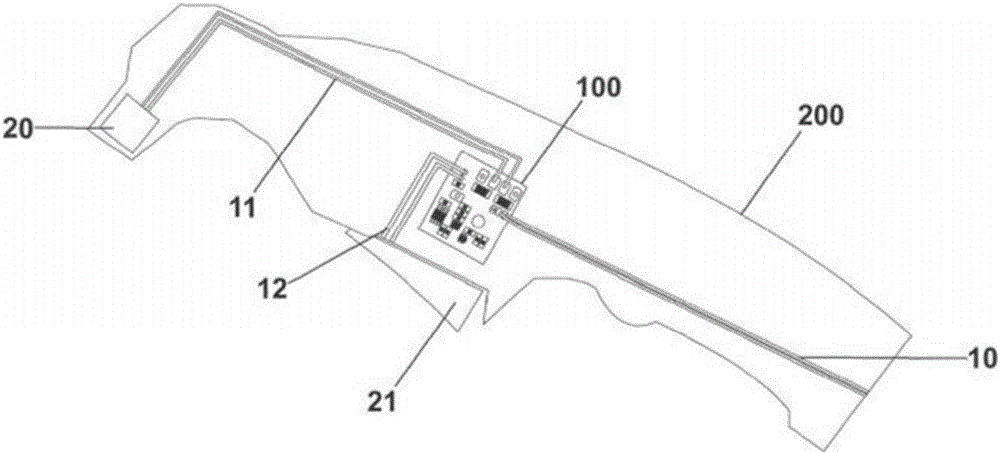

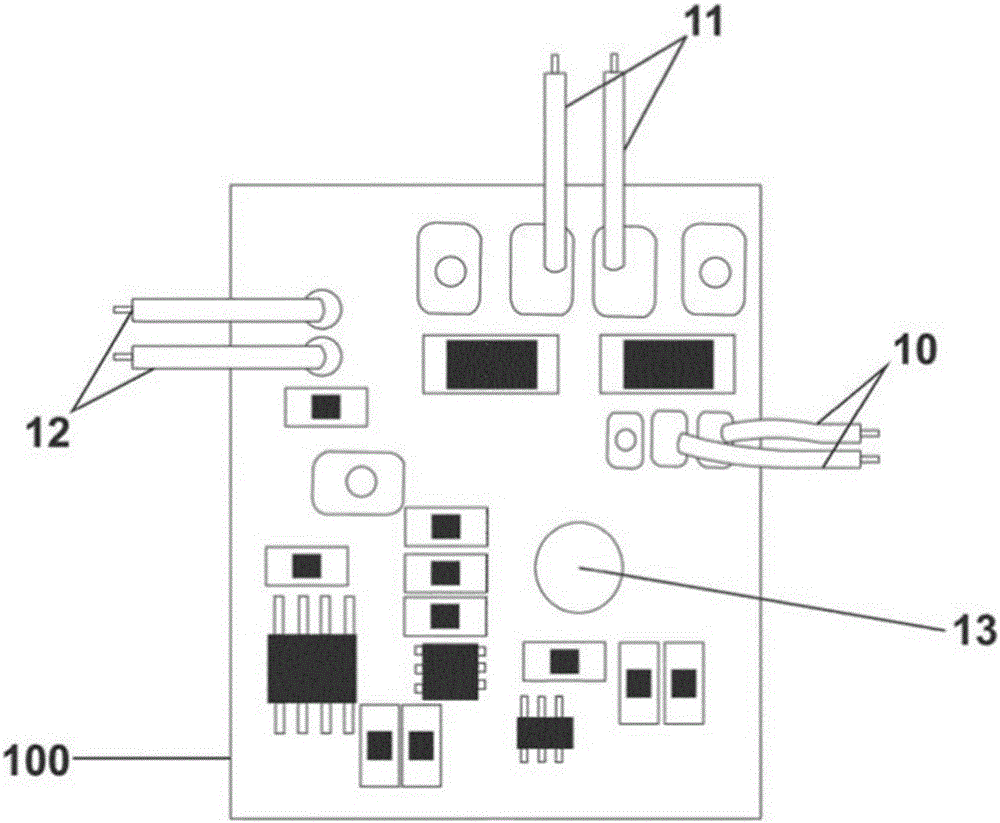

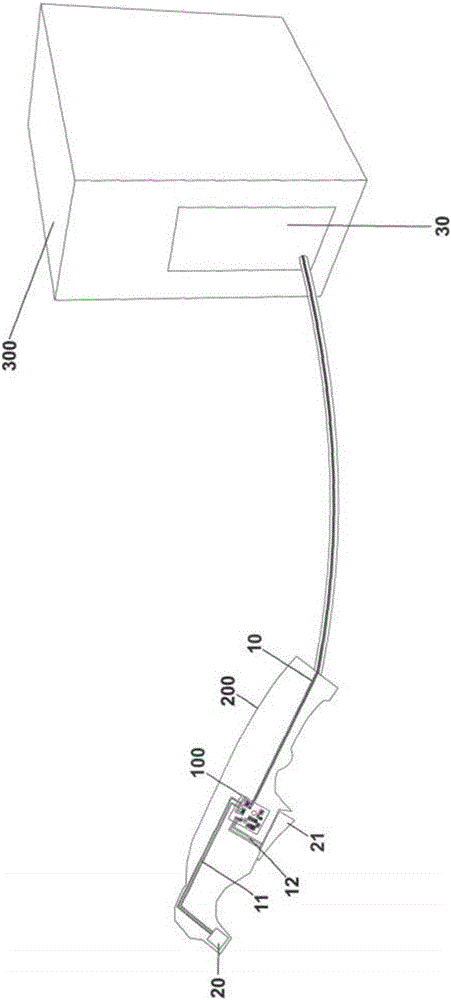

[0013] The control and identification circuit of the plasma torch, based on the purpose of the present invention, describes an electronic circuit (100) that is provided with a microcontroller in the plasma torch (200), and is used to realize the circuit (100) and the equipment box (300 ) two wires (10) called "network" for power transmission to control and identify the central circuit board (30) of the plasma torch (200) and equipment box (300).

[0014] The core of the electronic circuit board (100) is based on a microcontroller which provides safety control of the flare nozzle (20) via two connecting wires (11) connecting the circuit board (100) and the flare nozzle (20) For protection, the above connecting wire (11) can also provide power control for the torch together with the circuit board (100). In addition, the electronic circuit board (100) also provides trigger activation control through two connecting wires (12) between the circuit board (100) and the plasma torch tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com