Probe pin and electronic device with same

A probe and electroforming technology, applied in the direction of measuring electricity, measuring electrical variables, components of electrical measuring instruments, etc., can solve the problems of unsuitable miniaturization, lengthening of elastic parts, and narrowing of the interval of elastic parts, etc. Effects of degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0065] Hereinafter, embodiments of an inspection unit including a probe of the present invention will be described with reference to the drawings. In addition, in the following description, terms indicating directions such as "upper", "lower", "left", "right" and other terms including them are used to describe the structures shown in the drawings, but these The purpose of the terms is to facilitate understanding of the embodiments through the drawings. Therefore, these terms only show the direction when the embodiments of the present invention are actually used, and these terms should not be used to limitably interpret the technical scope of the invention described in the scope of claims.

no. 1 approach

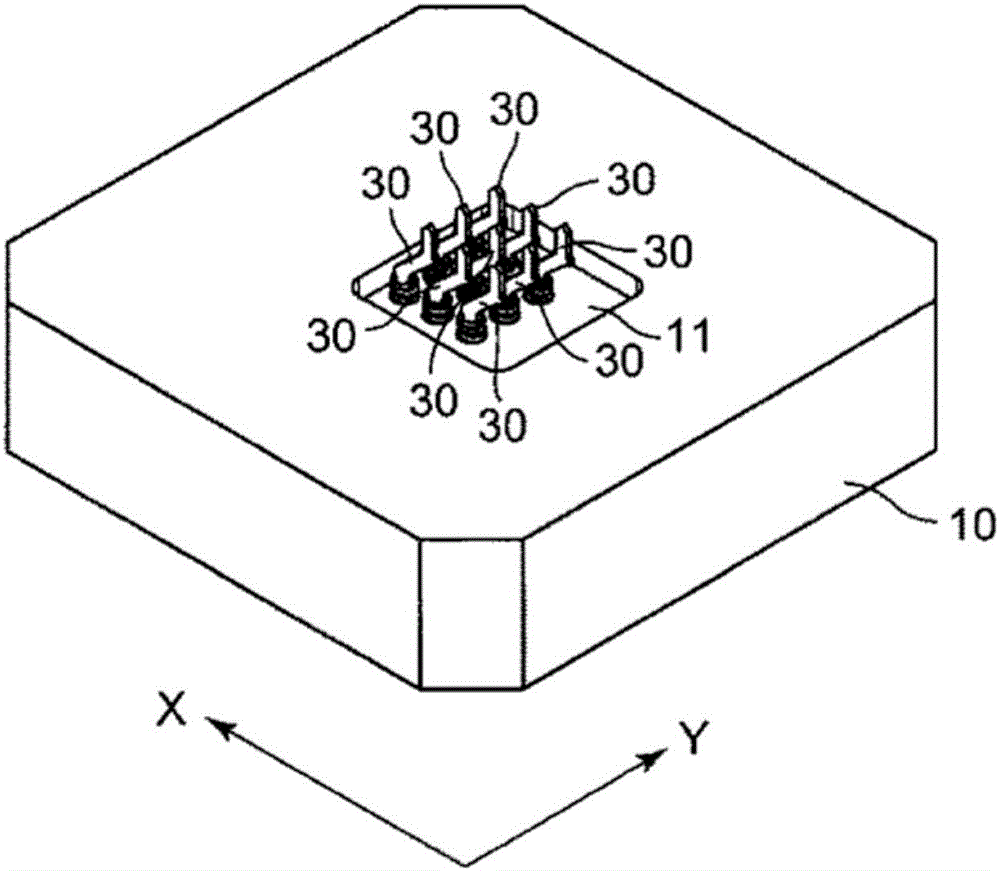

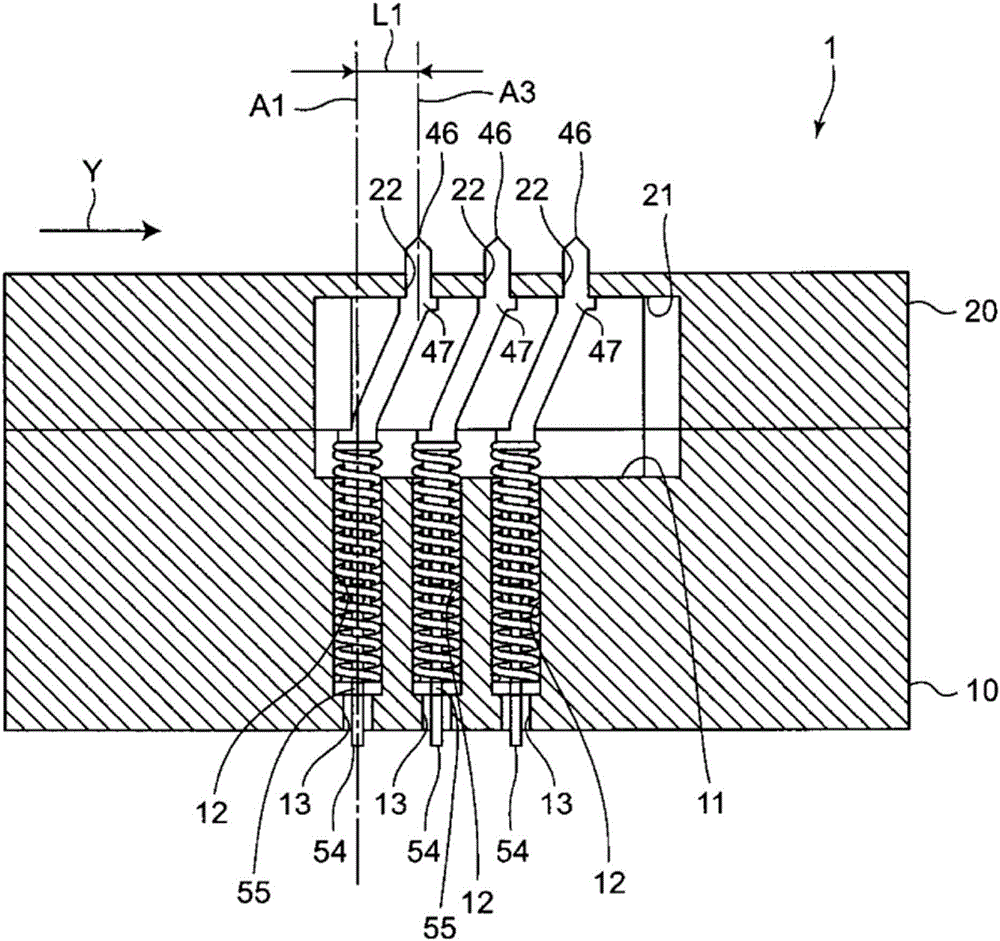

[0067] figure 1 It is a perspective view of an example of an inspection unit equipped with a probe according to the first embodiment of the present invention, figure 2 is to remove figure 1 A perspective view showing the state of a part of the inspection unit, image 3 is along figure 1 Sectional view of line III-III.

[0068] like Figure 1 ~ Figure 3 As shown, the inspection unit 1 as an example of electronic equipment includes a case and the probe 30 of the first embodiment accommodated in the case. The housing is composed of a housing main body 10 and a housing cover 20 covering the housing main body 10 , and the probe 30 is housed in the housing main body 10 .

[0069] like figure 2 As shown, the case main body 10 has a planar shape in which four corners of a square are chamfered in plan view. A concave portion 11 is provided substantially at the center of the upper surface of the housing body 10 .

[0070] A plurality of housing portions 12 for housing the prob...

no. 2 approach

[0102] Figure 8 ~ Figure 13 It is a figure which shows an example of the probe 230 of 2nd Embodiment, and the inspection unit 201 provided with the probe 230 of 2nd Embodiment. In this second embodiment, the same reference numerals are assigned to the same parts as those in the first embodiment, and description thereof will be omitted, and points different from the first embodiment will be described. In addition, the inspection unit 201 is an example of electronic equipment.

[0103] like Figure 10 ~ Figure 13 As shown, the probe 230 of the second embodiment extends in the middle part 242 of the first plunger 140 along a direction that is 90 degrees relative to the long side direction of the clamped part 41, and the contact part 43 extends along the direction relative to the middle The portion 142 is different from the probe 30 of the first embodiment in that the longitudinal direction of the portion 142 extends in a direction 90°. That is, the probe 230 is configured suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com