Steam-water separating box drainage system of sealing oil vacuum pump

A steam-water separation and drainage system technology, applied in the field of separator drainage system, can solve problems such as increased workload of operating personnel, potential safety hazards, damage to mechanical equipment, etc., to prevent lubricant oil overflow, reduce personnel monitoring, and improve drainage speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

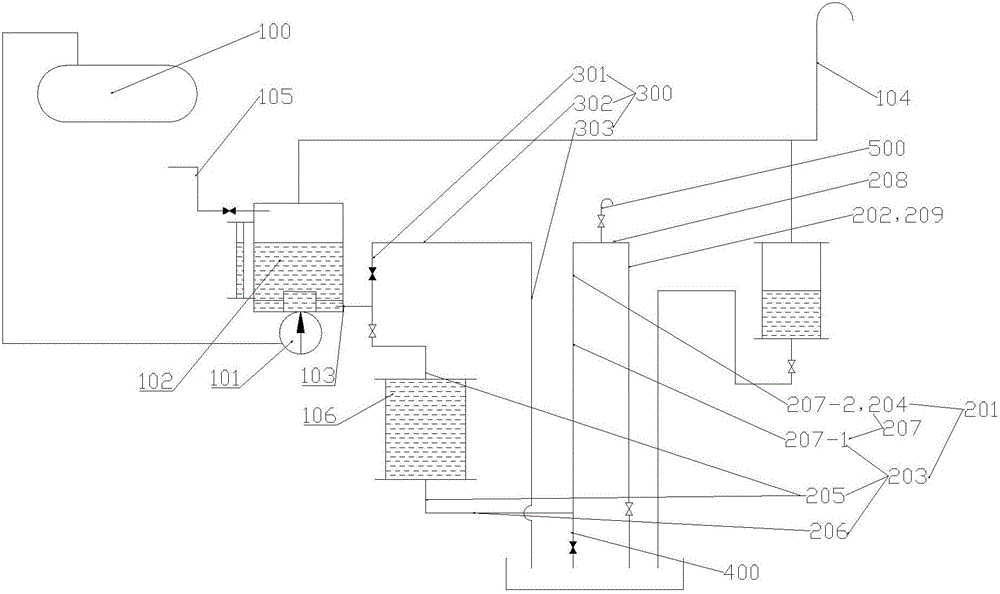

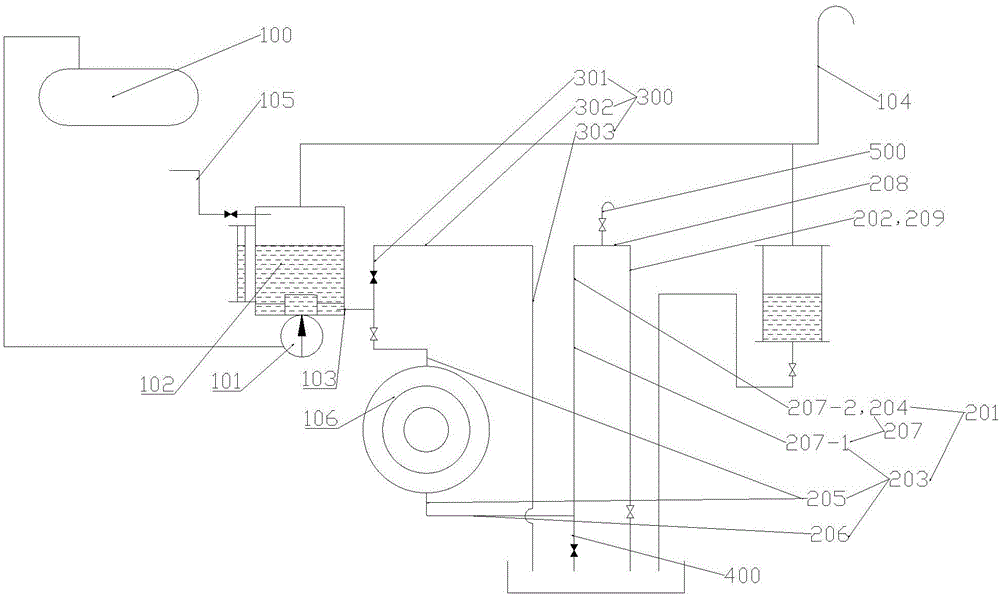

[0049] Such as figure 1 As shown, the generator sealing oil system includes a sealing oil vacuum box 100, a vacuum pump for discharging moisture in the sealing oil vacuum box 100 and a drainage system of a steam-water separation box 102 of the vacuum pump. The vacuum pump includes a vacuum pump body 101 and a steam-water separation box 102 , the drainage system of the steam-water separation tank 102 of the vacuum pump includes an overflow pipeline communicated with the steam-water separation tank 102 . The air inlet of the vacuum pump body 101 communicates with the sealing oil vacuum box 100, and the moisture in the sealing oil vacuum box 100 is extracted through the vacuum pump, and the exhaust port of the vacuum pump body 101 communicates with the steam-water separation box 102, and the extracted gas is discharged into the steam-water Separation box 102.

[0050] An exhaust pipe 104 is arranged on the top of the steam-water separation box 102, and an oil replenishment pipe ...

Embodiment 2

[0073] Such as figure 1 As shown, on the basis of Embodiment 1, the drainage system of the steam-water separation tank 102 of this embodiment also includes an oil discharge pipeline 400 for quickly discharging the liquid in the buffer device 106, and the oil discharge pipeline 400 and the buffer device 106 communicates with or communicates with the overflow pipeline that is positioned at buffer device 106 lower parts.

[0074]When the discharge speed of the liquid in the steam-water separation tank 102 is too fast, the buffer device 106 is full and even overflows at the liquid outlet of the overflow pipeline, the liquid in the buffer device 106 can be quickly discharged by opening the oil discharge pipeline 400 quickly reduce the liquid pressure in the overflow pipeline, stop spraying liquid, and improve the safety of the overflow pipeline. At the same time, when the sealing oil system breaks down or is overhauled, by opening the oil discharge pipeline 400, the steam-water sep...

Embodiment 3

[0081] Such as figure 1 As shown, on the basis of Embodiment 1 and Embodiment 2, the drainage system of the steam-water separation tank 102 of the present embodiment also includes an overflow pipe 300 for rapidly reducing the liquid level in the steam-water separation tank 102. The inlet end of the pipe 300 communicates with the overflow pipeline between the buffer device 106 and the steam-water separation tank 102 .

[0082] Wherein the inlet end of the overflow pipe 300 can also communicate with the steam-water separation tank 102 .

[0083] By setting the overflow pipe 300, when the liquid in the steam-water separation box 102 increases too much or too fast, the overflow pipe 300 assists the overflow pipeline to reduce the liquid level in the steam-water separation box 102, so that the liquid level can be lowered as soon as possible to prevent overflow The liquid in the pipeline splashes and pollutes the surrounding space, causing danger.

[0084] Further, a control valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com