A truck tyre with an inner belt ply

A technology for trucks and tires, which is applied to tire parts, reinforcing layers of pneumatic tires, vehicle components, etc. It can solve the problems of reduced tire wear resistance and puncture resistance, increased tire rolling resistance, and poor crown rigidity. Achieve the effect of improving service life, reducing compression deformation and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

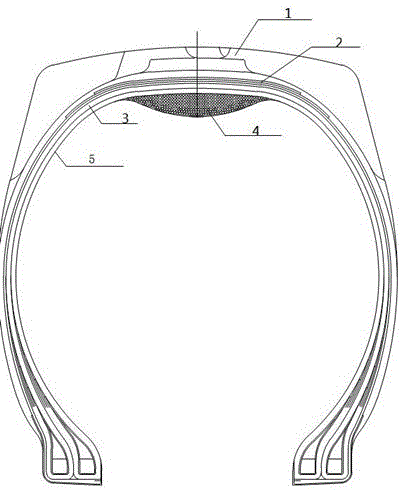

[0010] An inner-belted truck tire is provided with an inner belt layer structure 4 between tire inner-layer rubber 5 and carcass cords 3 .

[0011] The manufacturing method is as follows: First, the carcass layer 3, buffer layer 2 and tread rubber 1 are sequentially pasted on the first-stage forming machine and transferred to the second-stage forming drum, slowly inflated and the distance between the two chucks is adjusted to meet the construction specification. requirements, take it off and use it for later use. Then cut the inner belt layer according to the designed angle of 0~30°, stick it on the inner liner glue 5 of the second-stage forming machine head, and finally align the center line of the inner belt layer with the center line of the carcass cord 3 Fit together so that they coincide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com