A cell 3D printer

A 3D printer and cell technology, applied in the field of 3D printers that can print cells, can solve the problems of easy dislocation, inaccurate, clear, and difficult to locate the outline of the stent, and achieve the effect of improving the shape and size accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The above-mentioned features and advantages of the present invention can be better understood after reading the detailed description of the embodiments of the present disclosure in conjunction with the following drawings. In the drawings, components are not necessarily drawn to scale, and components with similar related properties or characteristics may have the same or similar reference numerals.

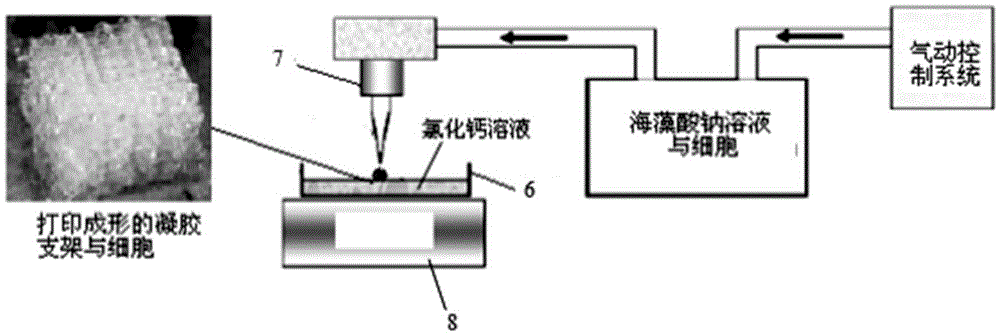

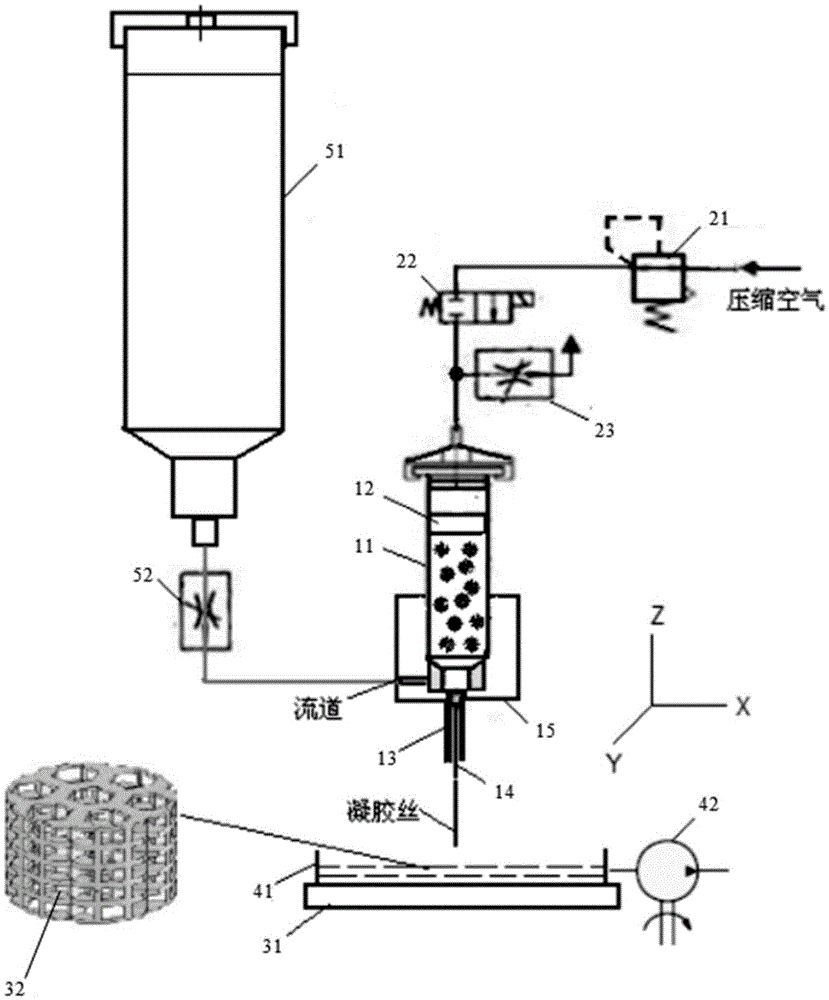

[0030] figure 2 The structure of an embodiment of the cell 3D printer of the present invention is shown. See figure 2 , The printer of this embodiment is composed of a nozzle, a feeding system, a pneumatic control system, a workbench, a liquid drainage system and a drive system.

[0031] The spray head includes: a syringe 11 , a piston 12 , a needle tube 13 , a needle 14 and a jacket 15 . The upper inlet of the syringe 11 is connected to the pneumatic control system through a hose, the lower end is matched with the needle tube 13 and the needle 14, and the inner cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com