Schoolhouse in-vitro reinforcing and strengthening method of prefabricated perforated plate brick mixed structure

A hybrid structure and perforated plate technology, applied in building construction, building maintenance, construction, etc., can solve problems such as long service life, low building quality, and reduced wall bearing capacity, achieving significant economic and social benefits , broad prospects for popularization and application, and improved seismic fortification capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

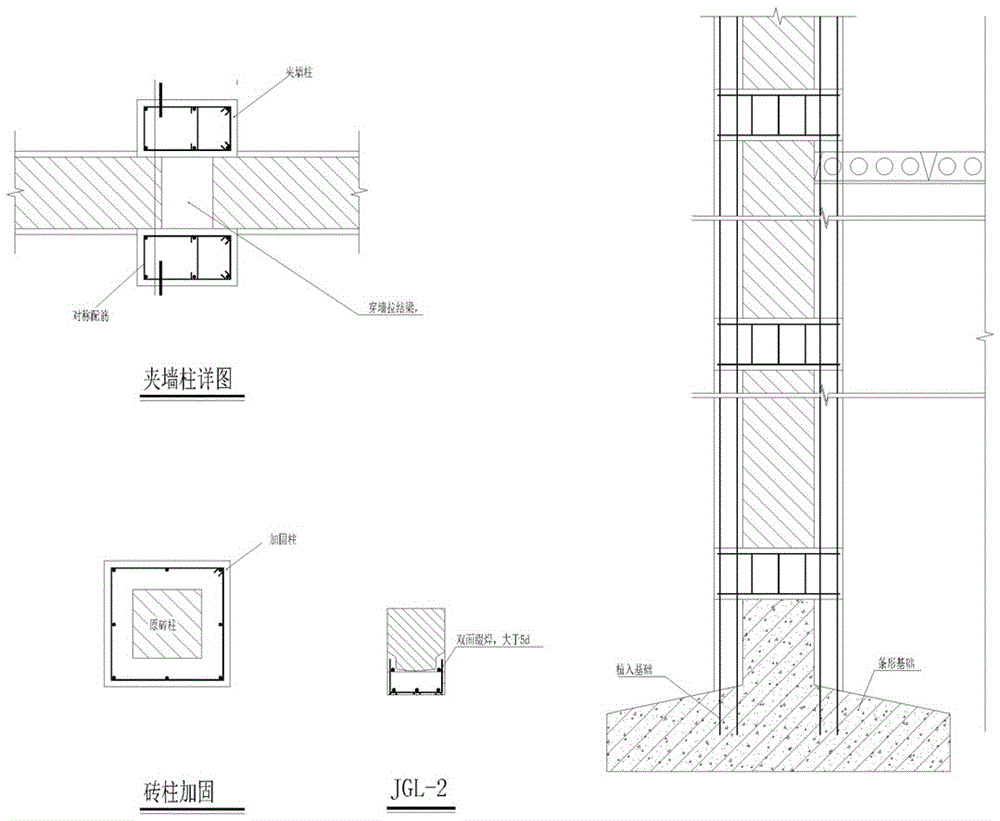

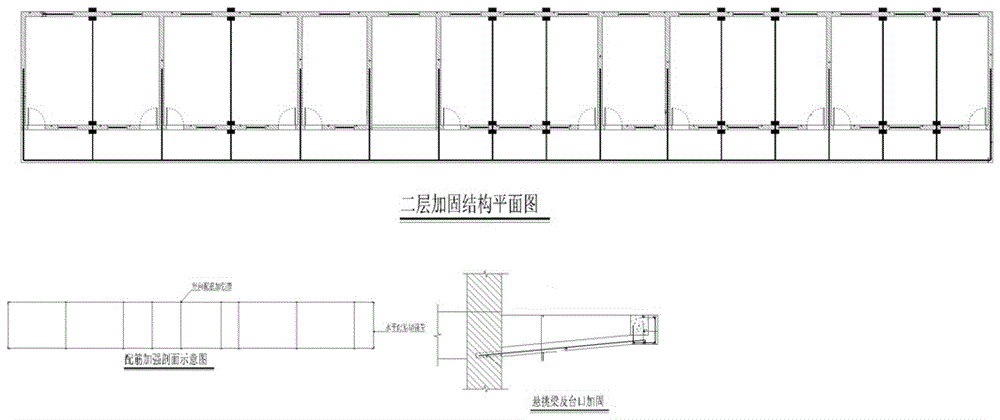

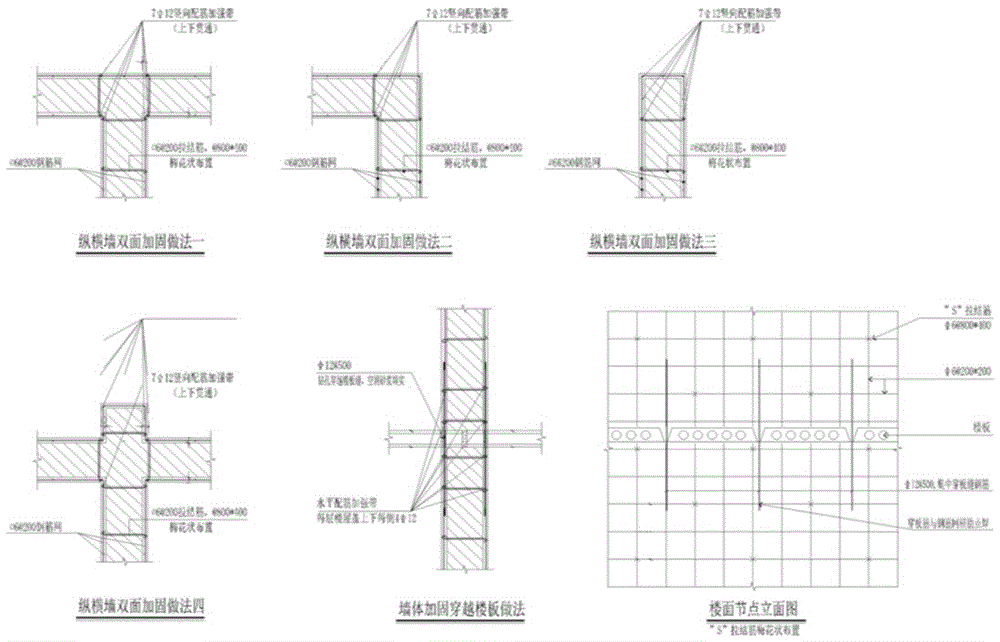

[0037] Refer to attached Figure 1-8 .

[0038] Construction method of the present invention is specifically as follows:

[0039](1) External lattice structure column construction and independent brick column reinforcement: The lattice structure column is generally set at the longitudinal wall where the simply supported girder rests, and has a reliable connection with the ring beam and the wall. Yes: first locate at the bottom of the beam to determine the 350×200 section size on each side of the external double-sided column, and implant 6φ14 longitudinal steel bars into the foundation with the method of planting bars and bind φ6@150 stirrups. The top of the longitudinal bars meets a ring beam Or girder, it must be connected through the ring beam or the reinforcement at the bottom of the girder, re-plant the reinforcement on the back of the beam to connect the longitudinal reinforcement, and then take 250×180 penetration holes in the wall every 620 mm along the longitudinal wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com