Shaft furnace feeding hopper

The technology of a hopper and a shaft furnace is applied in the field of a feeding hopper device, which can solve the problems of not being able to load a plurality of cathode copper plates well, covering the furnace mouth, and uneven height of the cathode copper plates, etc. The effect of long life and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

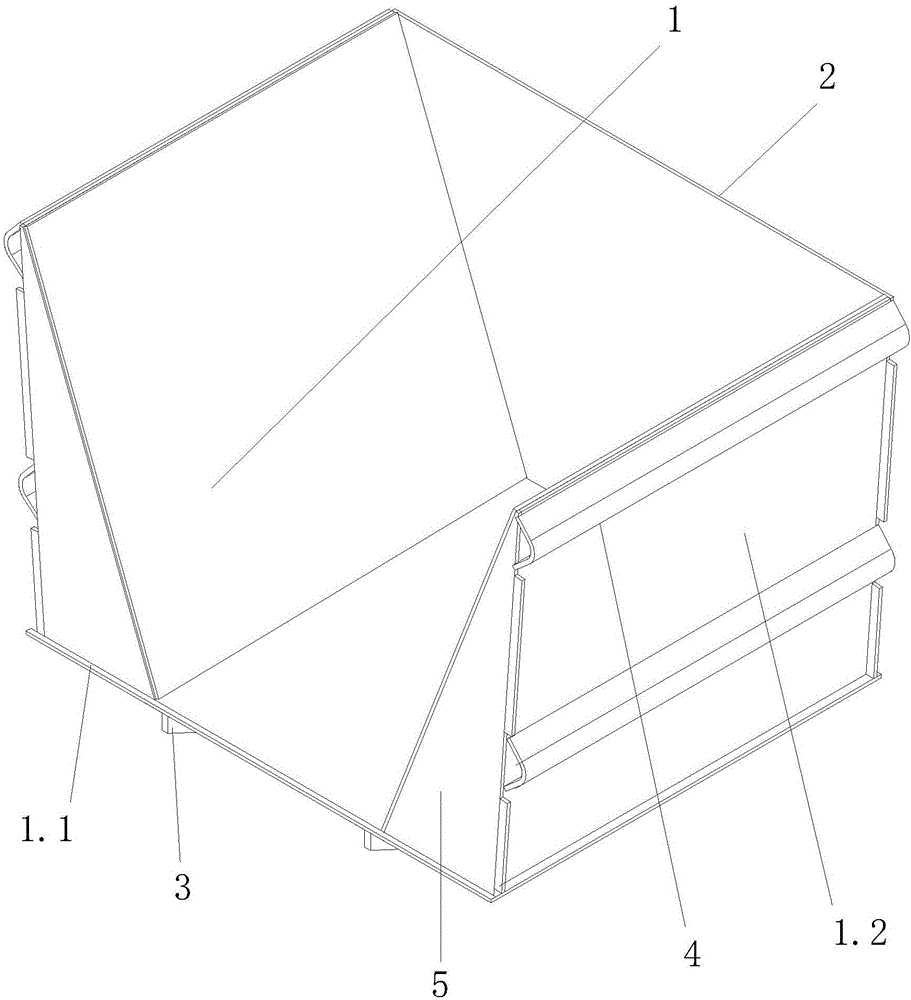

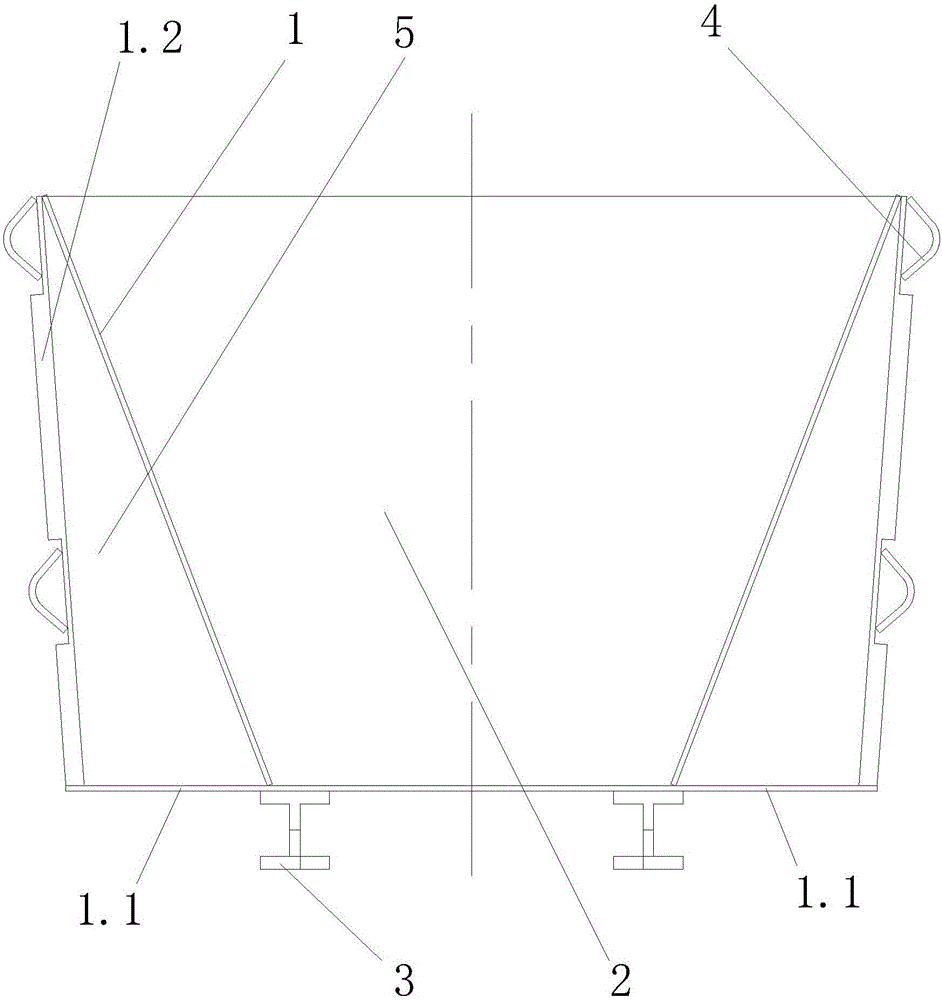

[0017] Such as figure 1 , figure 2 As shown, the present invention includes a hopper body, and the hopper body includes a hopper body 1 with a trapezoidal cross section. In this embodiment, the hopper main body 1 is composed of three steel plates, the bottom of the hopper main body 1 is composed of a whole steel plate and extends to the left and right sides to form an extension 1.1, the end of the extension 1.1 and the trapezoidal waist of the hopper main body 1 Between the upper edge of the upper part is provided with a connecting plate 1.2, and the end of the extension part 1.1 is fixedly connected by the upper edge of the trapezoidal waist of the connecting plate 1.2 and the hopper main body 1. The front end of the hopper main body 1 is open, and the rear end is fixedly connected with a baffle pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com