Heat state direct reduction iron furnace external cooling device and method

A cooling device and external cooling technology, applied in the direction of furnaces, shaft furnaces, furnace components, etc., can solve the problems of increased space height of vertical furnaces, easy bursting of materials, and reduced iron metallization rate, so as to save engineering investment costs and improve cooling effect Uniform, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

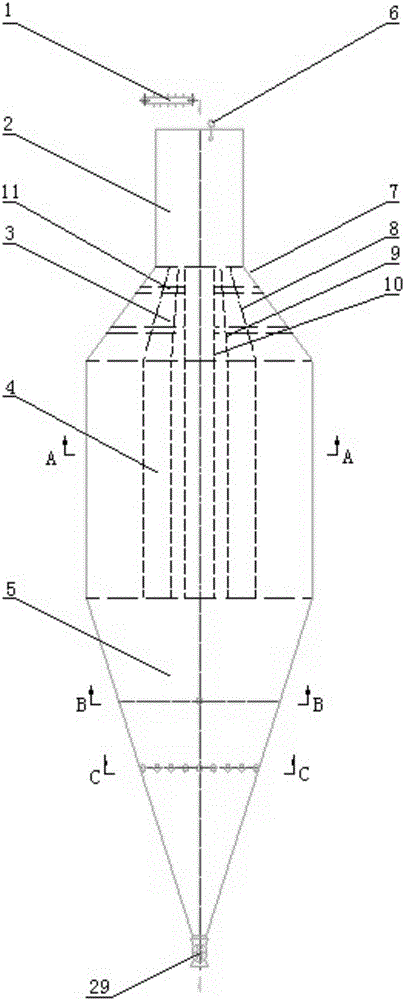

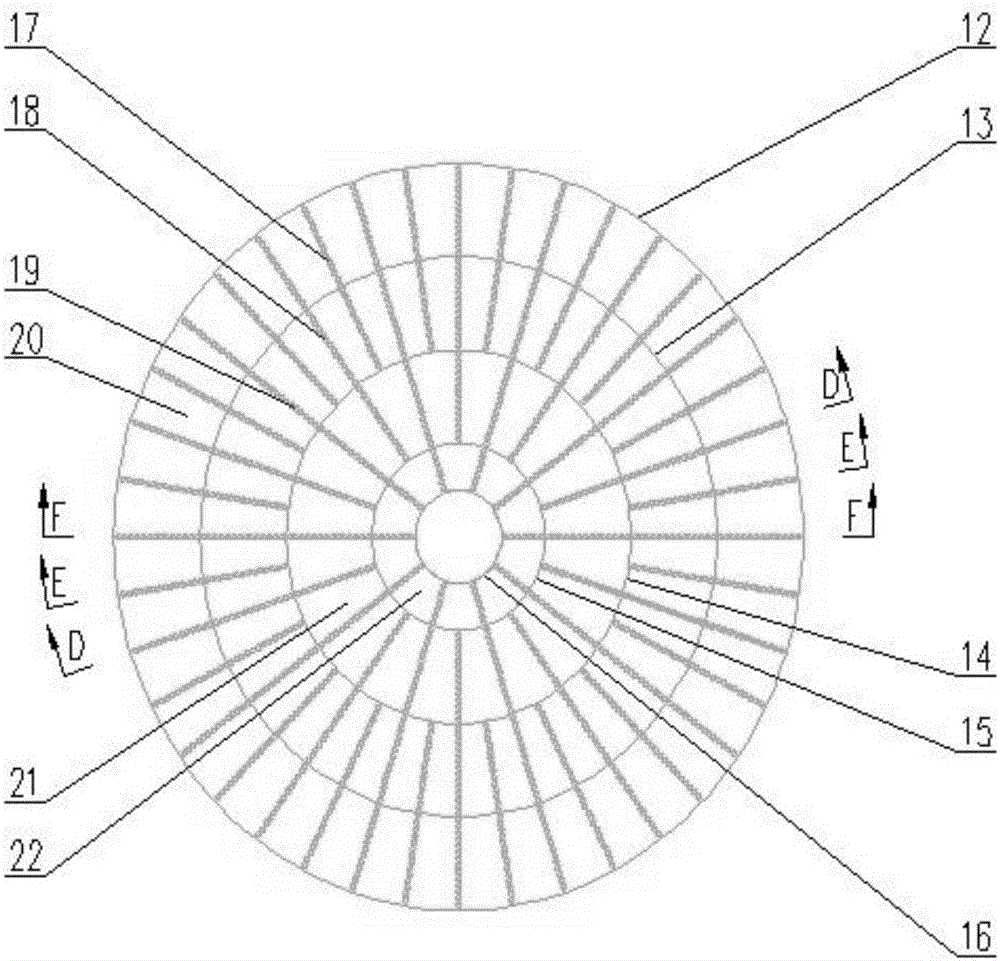

[0035] A thermal direct reduction iron furnace external cooling device according to the present invention includes a cooling device; the cooling device is composed of a buffer chamber 2, a distribution chamber 3, a cooling chamber 4 and a discharge chamber 5 arranged sequentially from top to bottom; the buffer The top of the chamber 2 is provided with a feed inlet; the distribution chamber 3 is coaxially provided with a cylindrical cylinder 10 and three conical cylinders 7-9 from the inside to the outside, wherein the top of the cylindrical cylinder 10 is closed, and the cylindrical The outer side of the cylinder 10 forms three bell mouth-shaped annular material passages that expand downward in sequence; the bottom of the cylindrical cylinder 10 and the conical cylinder 7-9 and the outer shell 12 of the cooling chamber 4 and three annular partition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com