Rotor wing propeller hub connecting piece fatigue test load debugging method

A fatigue test and rotor hub technology, which is applied in the field of fatigue test load debugging of helicopter rotor hub connectors, can solve the problems of inability to apply variable-pitch tie rod force, inability to apply damping force, and conservative service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below.

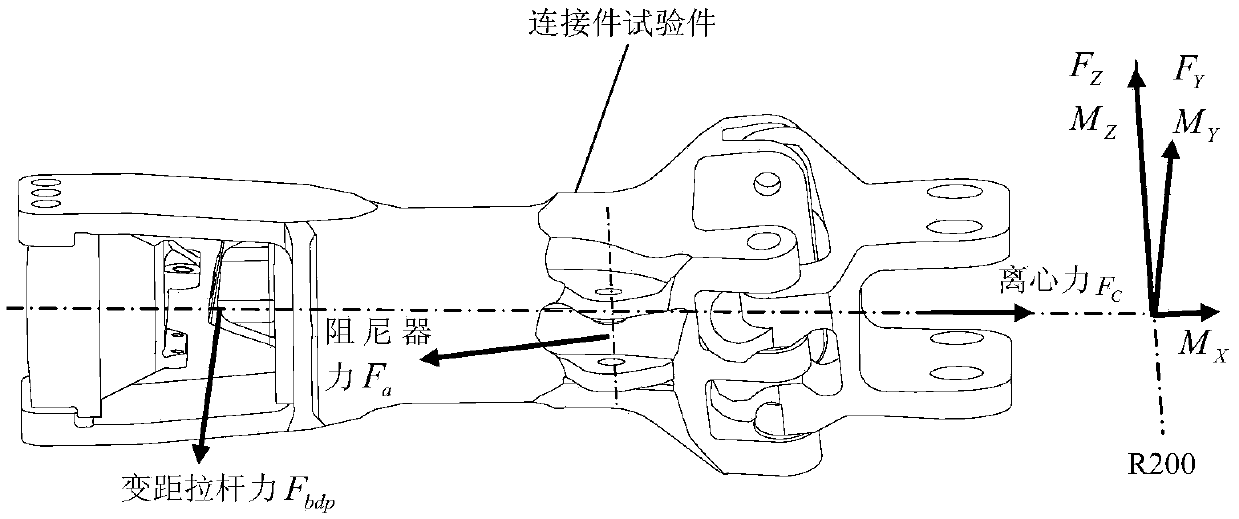

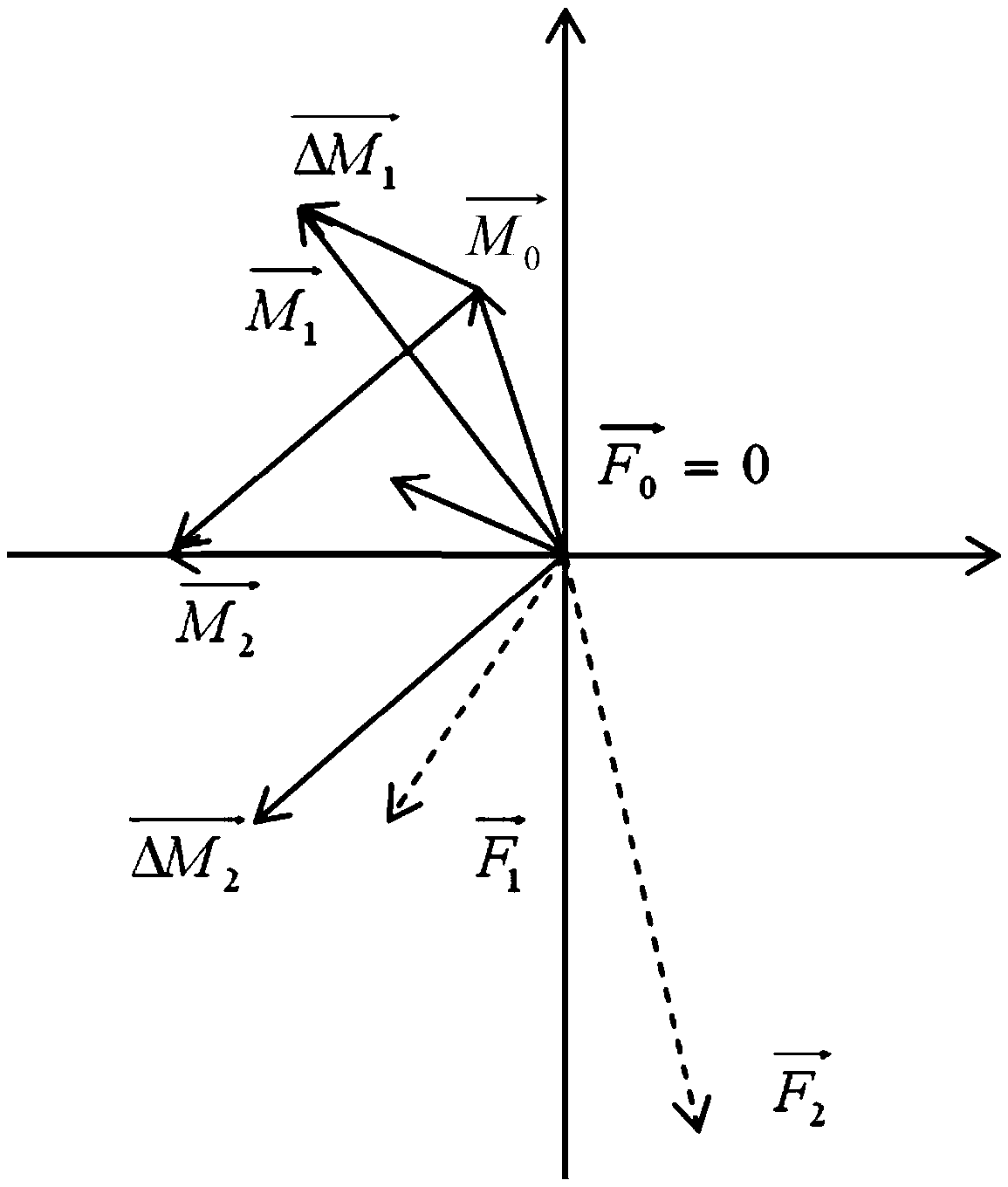

[0020] Such as figure 1 , the load to be simulated in the fatigue test of the main propeller hub connector is the damper force F a , pull rod force F bdp , centrifugal force F c , Torque M X (produced by the force of the variable pitch rod), swinging moment M Y and wielding shear force F Z (generated by the swinging shear force actuator), shimmy bending moment M Z and shimmy shear force F Y (generated by the shimmy shear actuator), each load is loaded in phase coordination. Such as figure 2 , a vector composite diagram for bending moment debugging.

[0021] A method for debugging fatigue test loads of rotor main propeller hub connectors, characterized in that the steps of the method for debugging test loads are as follows:

[0022] (1) Configure and debug the parameters of the load channels of centrifugal force, variable pitch rod force, damper force, shimmy force, and swing force, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com