In-situ cup drawing device

A cupping, in-situ technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to maintain the loaded state, complex equipment, etc., and achieve the effect of reducing experimental costs, small size, and ensuring accuracy and rationality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

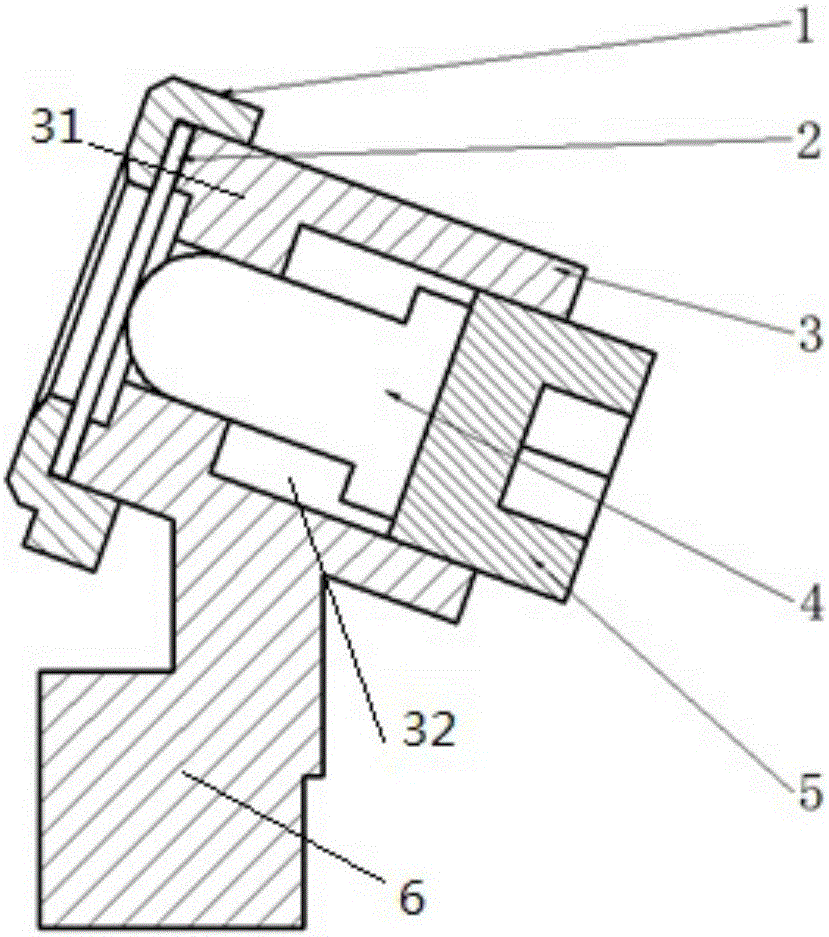

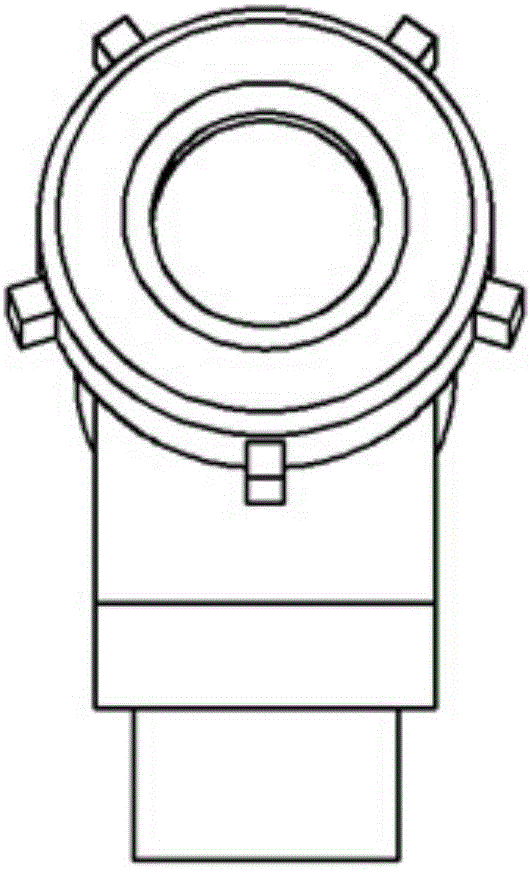

[0015] Such as figure 1 The in-situ cupping device shown includes a base 6, a cylinder 3 obliquely arranged on the base, a pressing part 1, a transitional pressing bar 4 and a loading part 5, and the bottom of the transitional pressing bar 4 is in contact with the loading part 5 , the top end of the cylinder 3 places the sample piece 2 and is compressed by the pressing part 1 , and the transition pressure rod 4 is pushed into the inner cavity 32 of the cylinder 3 by the rotation of the loading part 5 at the bottom end.

[0016] In this embodiment, the pressing part 1 is a blanking nut, the loading part 5 is a loading nut, and the inclination between the axis of the cylinder and the vertical direction is 70°, which is suitable for EBSD testing in common electron microscopes, and can also be used as needed Pick a specific other angle. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com