Real-time as-fired coal burning caloricity monitoring system and monitoring method thereof

A technology of real-time monitoring and coal burning in the furnace, applied in the direction of power measurement, measuring device, torque measurement, etc., can solve the problems of lack of targeted treatment of boiler body differences, difficulty in adapting to industrial sites, lack of localized development, etc., to achieve The effects of avoiding boiler flameout accidents, reducing coal consumption for power supply, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings.

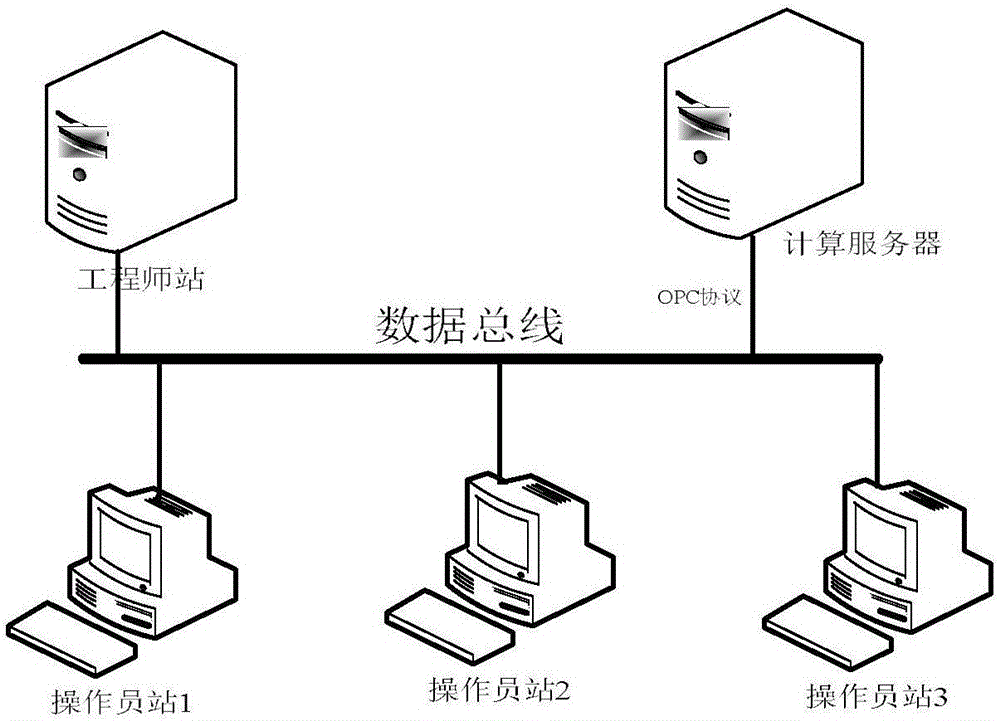

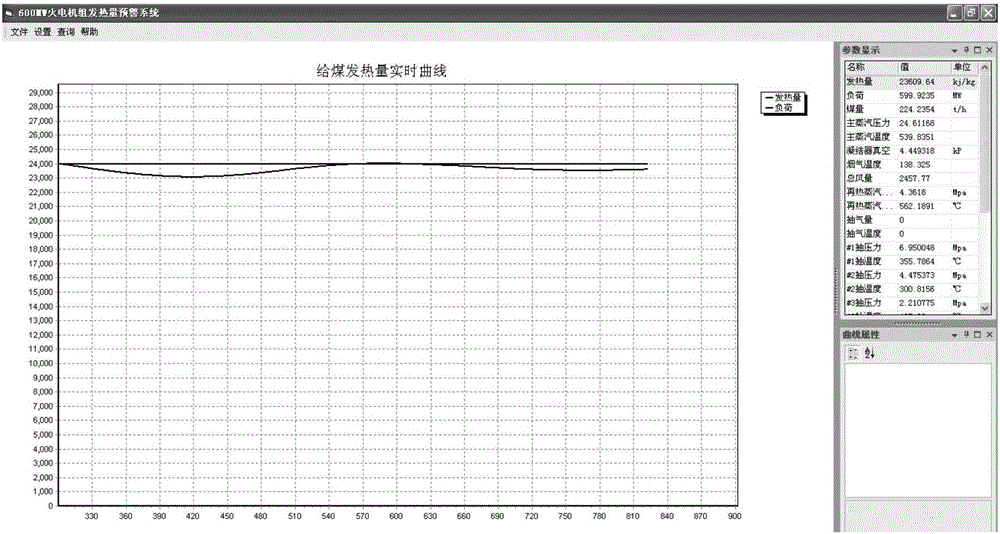

[0025] Such as figure 1 As shown, the present invention is a real-time monitoring system for the calorific value of coal fired into the furnace. The system uses modern engineering thermophysical algorithms and modern computer technology to establish real-time monitoring of boiler combustion. The system includes engineer stations and The operator station, the engineer station and the operator station are respectively connected to the calculation server of the DCS system of the generator set through the system bus, and it is characterized in that: the real-time monitoring system is connected with the DCS system of the generator set through the Ethernet, and from the generator set The real-time calculation data is obtained on the data bus of the DCS system, and the real-time calculation data is sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com