External descending chamber layout device and measurement method capable of accurately measuring core flow

An accurate measurement, external technology, applied in the direction of measuring fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, reactor, etc., can solve the problem that the core flow cannot be accurately measured, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

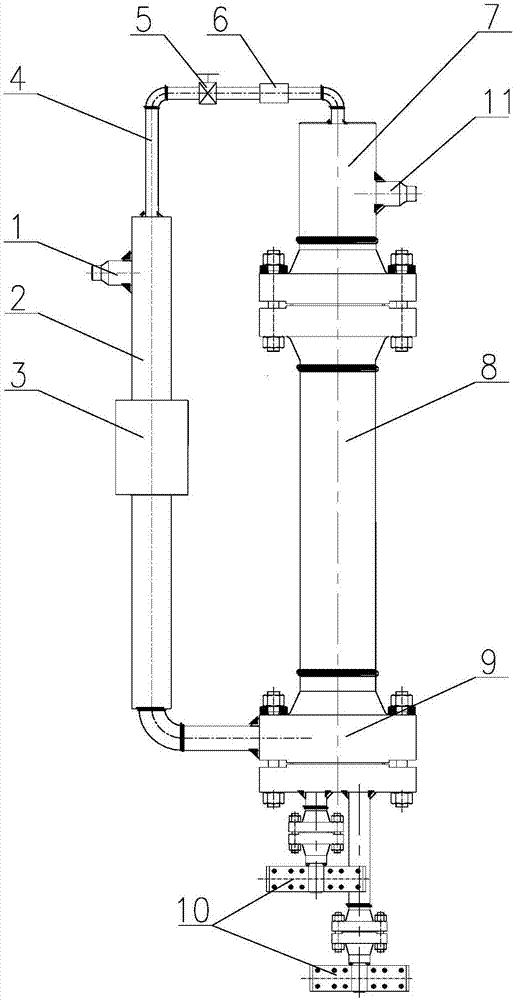

[0058] Such as figure 1 As shown, the external descending chamber layout device that can accurately measure the core flow rate includes a core simulation section 8, the lower end of which is communicated with the descending section pipeline 2 through a lower flange 9, and the descending section The bottom end of the pipeline 2 is welded with the perforated lower flange 9 through an elbow, the lower end of the lower flange 9 is provided with a power supply copper bar 10, and the descending section pipeline 2 is provided with a first flow meter 3, The upper end of the core simulation section 8 communicates with the upper head 7 through the upper flange, the upper side of the descending section pipeline 2 is welded with an inlet pipe 1, and the side of the upper head 7 is welded with an outlet pipe 11. Including a bypass pipeline 4, one end of the bypass pipeline 4 communicates with the descending pipeline 2, preferably, the flow pipeline 4 is welded with the descending pipeline ...

Embodiment 2

[0061] Such as figure 1 As shown, this embodiment is based on Embodiment 1, the bypass pipeline 4 is provided with an orifice 5 , and the diameter of the orifice 5 is adjustable.

[0062] Experimental process of this embodiment: By adjusting the resistance of the orifice 5 , the simulation of bypass flow under different working conditions can be realized.

Embodiment 3

[0064] This embodiment is based on Embodiment 1 or Embodiment 2, and the diameter of the bypass pipeline 4 is 1 / 4 of the diameter of the pipeline 2 in the descending section.

[0065] A method for measuring flow based on the external descending chamber arrangement device described in Embodiment 2, comprising the following steps:

[0066] 1) Adjust the resistance of the bypass pipeline: adjust the hole diameter of the orifice plate 5 on the bypass pipeline 4 to make the pressure drop Δp of the bypass pipeline 4 under the reference working condition m and design value Δp s The deviation is within ±5%;

[0067] 2), measurement of flow rate: the flow rate W flowing through the simulation section 8 of the core is measured by the first flowmeter 3 1 , the flow rate W of the bypass pipeline 4 is measured by the second flowmeter 6 2 .

[0068] Specific steps for adjusting the resistance of the bypass pipeline 4 through the orifice 5:

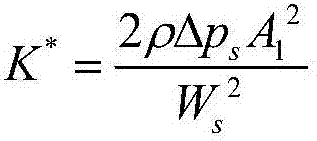

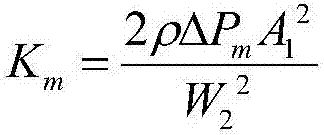

[0069] 1) Determine the resistance coefficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com