System and method for measuring equivalent moment of inertia of diesel engine

A diesel engine and moment of inertia technology, which is applied in the direction of measuring devices, machine/structural component testing, static/dynamic balance testing, etc., can solve the problems of cumbersome operation, poor realizability, low measurement accuracy and repeatability, and achieve Strong operability, high measurement accuracy, and portable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

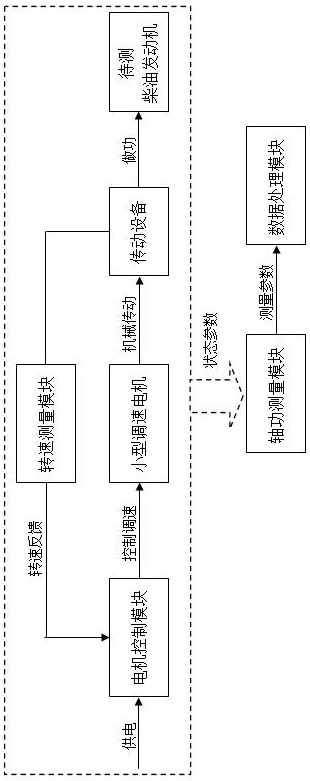

[0039] A system for measuring the equivalent moment of inertia of a diesel engine, including a transmission device, a small speed-regulating motor, a motor control module, a rotational speed measurement module, a shaft power measurement module and a data processing module;

[0040]Both ends of the transmission equipment are mechanically connected with the output shaft of the diesel engine to be tested and the shaft of the speed-regulating motor, and transmit the power and motion generated by the speed-regulating motor to the diesel engine;

[0041] The motor control module is used to control the working parameters of the small speed-regulating motor, and drives the speed-regulating motor to work during the measurement of the equivalent moment of inertia of the diesel engine to be tested;

[0042] The speed measurement module is used to detect the speed signal of the output shaft end of the diesel engine to be tested in real time and transmit it to the motor control module. The ...

Embodiment 2

[0061] The invention discloses a method and system for accurately measuring the equivalent moment of inertia of an on-site diesel engine based on the law of energy conservation, aiming at the current situation that the existing measuring method cannot accurately measure the equivalent moment of inertia of an industrial on-site diesel engine.

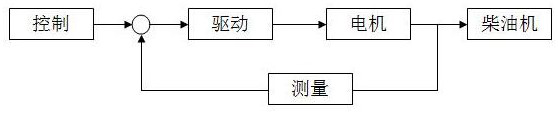

[0062] The module block diagram of the system is as follows: figure 1 As shown, it includes a diesel engine to be tested, transmission equipment, a small speed-regulating motor, a motor control module, a rotational speed measurement module, a shaft power measurement module and a data processing module; It can be selected according to the site conditions, DC or AC motor can be used to ensure good speed regulation performance; the two ends of the transmission equipment are respectively connected with the output shaft of the diesel engine to be tested and the rotating shaft of the small speed regulation motor, and the transmission ratio is 1...

Embodiment 3

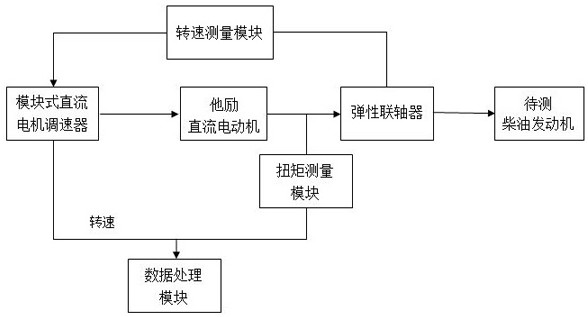

[0081] Such as image 3 and Figure 4 As shown, in this embodiment, the small speed-regulating motor is selected from the existing separately excited DC motor with good speed-regulating performance and high processing precision, which occupies a small area and is suitable for layout on the job site, and has a wide speed-regulating range and good smoothness.

[0082] In this embodiment, the transmission equipment selects an elastic coupling with excellent vibration reduction performance and a transmission ratio of 1:1, one side is connected with the separately excited DC motor 6, and the other side is connected with the output shaft of the diesel engine, which has a relatively high torque affordability and rigidity.

[0083] In this embodiment, the motor control module selects a modular DC motor speed controller matched with a separately excited DC motor, which is often used in speed regulation of industrial DC motors. The speed governor integrates power supply, control and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com