Preparation method of ball clay for ceramic body

A technology of ceramic blanks and ball clay, which is applied in the field of preparation of ball clay for ceramic blanks, can solve the problems of natural resource consumption, reduce glaze surface pinholes and air bubbles, rationalize particle distribution, and improve the combination of luster and green body Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

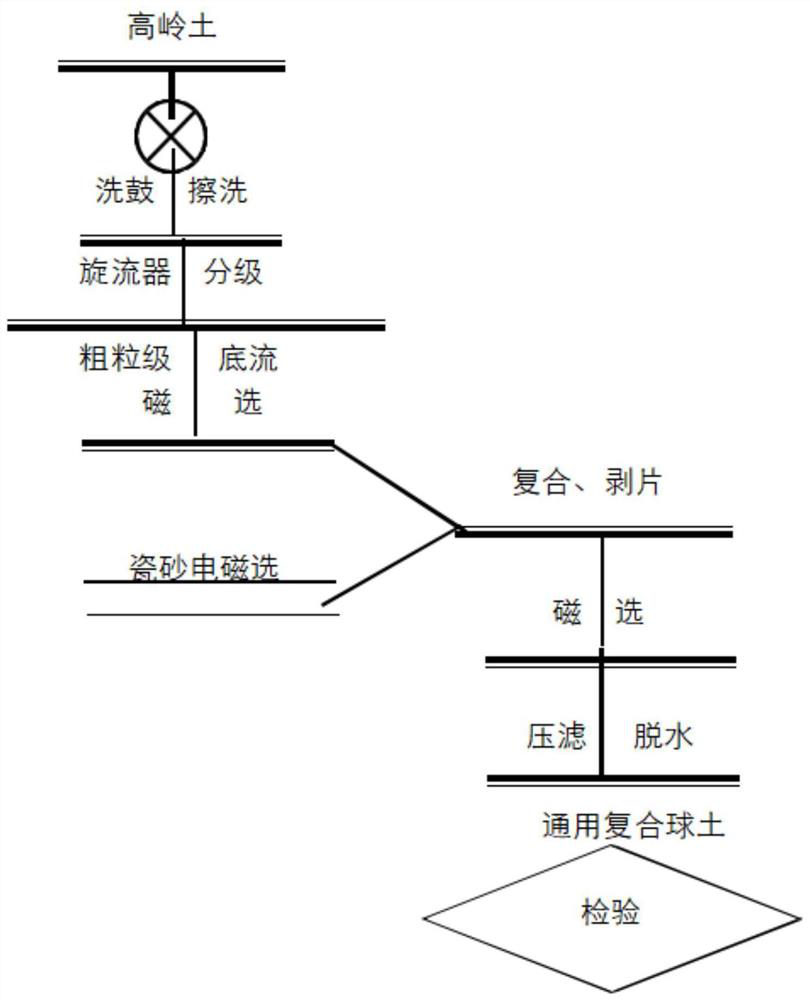

[0029] The invention provides a method for preparing ball clay for ceramic billets. figure 1 The preparation process for ceramic universal composite ball clay specifically includes the following steps:

[0030] Step 1, preparation of coarse-grained kaolin

[0031] Step 1.1, grading: Put kaolin into the slurry tank for mashing and add dispersant water glass to obtain a slurry with a concentration of 15%. The slurry is classified by a Φ75 type cyclone, and the bottom flow is taken for later use;

[0032] Step 1.2, peeling: the graded kaolin underflow is subjected to high-speed shearing and peeling through a peeling machine;

[0033] Step 1.3, Magnetic Separation: Purify the peeled slurry through an electromagnetic high-gradient magnetic separator, and enrich to obtain coarse-grained kaolin.

[0034] Step 2, preparation of porcelain white sand

[0035] The secondary tailings of kaolin are firstly pre-selected by a permanent magnet plate magnetic separator, then selected by an ...

Embodiment 2

[0042] Except that the mass ratio of coarse-grained kaolin and porcelain white sand in step 3.1 in Example 1 was changed to 85:15, other steps were consistent with Example 1, and the mud cake obtained at last was numbered mud cake 2.

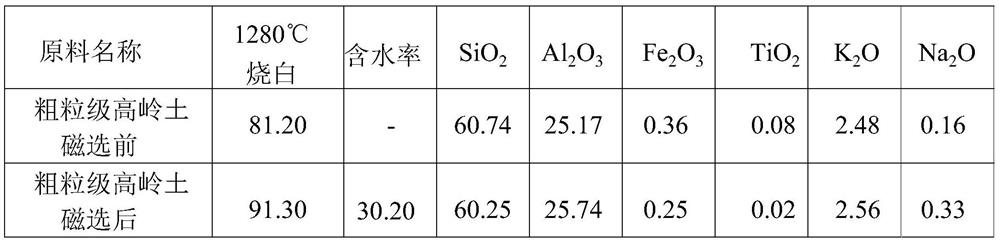

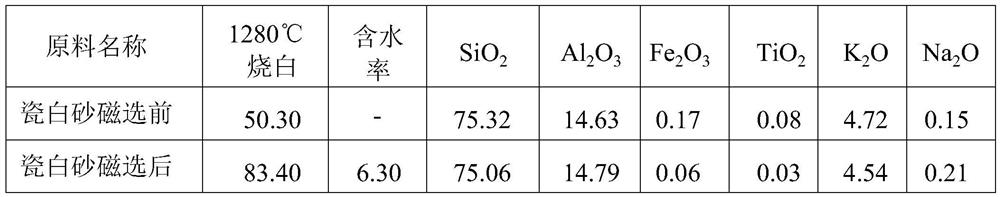

[0043] Among them, the whiteness and composition of coarse-grained kaolin before and after magnetic separation are shown in Table 1, and the whiteness value of coarse-grained kaolin after magnetic separation after calcination has increased to 91.3%; the whiteness value and composition of porcelain white sand before and after magnetic separation are shown in Table 1 2. The whiteness value of the porcelain white sand after magnetic separation after calcination has increased to 83.4%.

[0044] Whiteness and chemical composition (%) of table 1 coarse-grained grade kaolin

[0045]

[0046] Whiteness and chemical composition (%) of table 2 porcelain white sand

[0047]

[0048] The obtained mud cake 1 and mud cake 2 were calcined at 1280°C resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com