A low-temperature optical fiber sound sensor system

A technology of sound sensing and optical fiber, which is applied in the direction of measuring ultrasonic/sonic/infrasonic waves, instruments, measuring devices, etc. It can solve problems such as temperature compensation cannot be used, structural thermal expansion coefficient is nonlinear, and sensors cannot work normally, etc., to achieve harsh environments Powerful, easy-to-apply effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

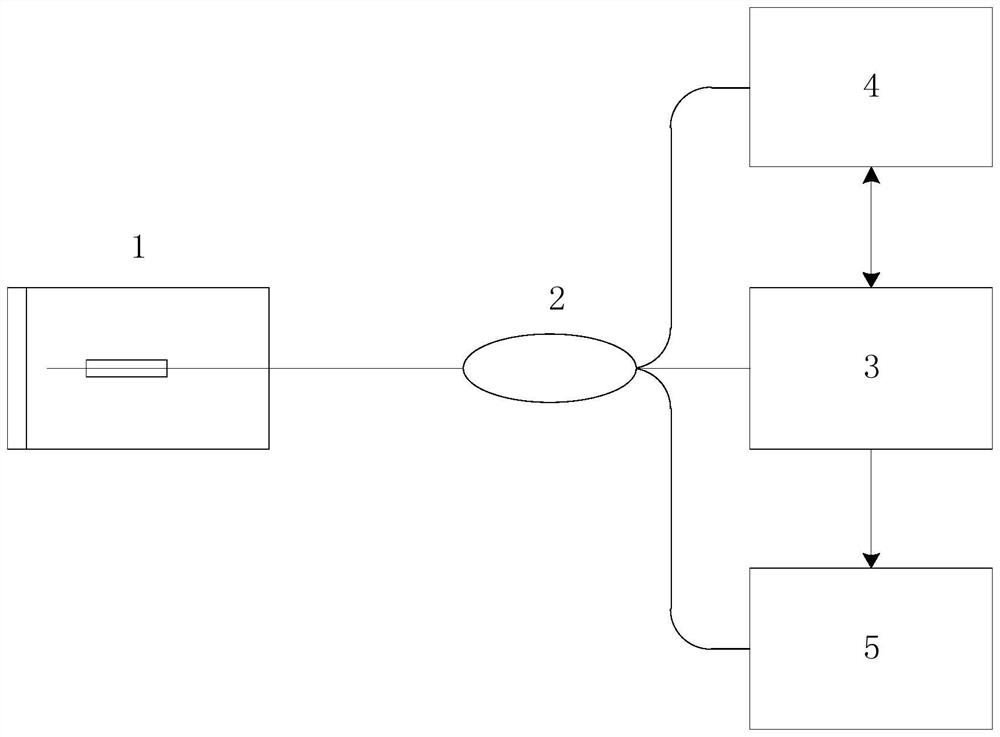

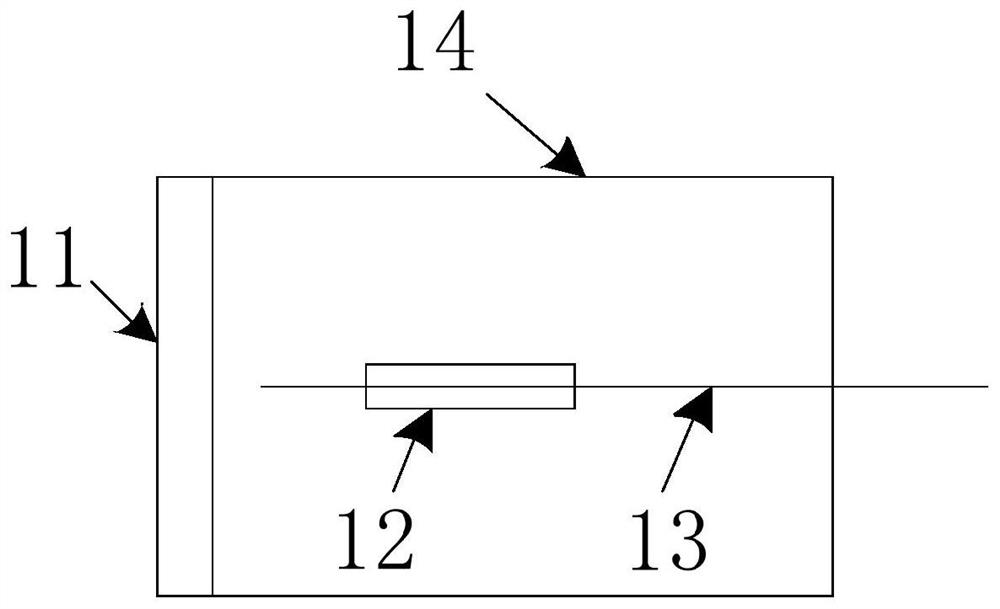

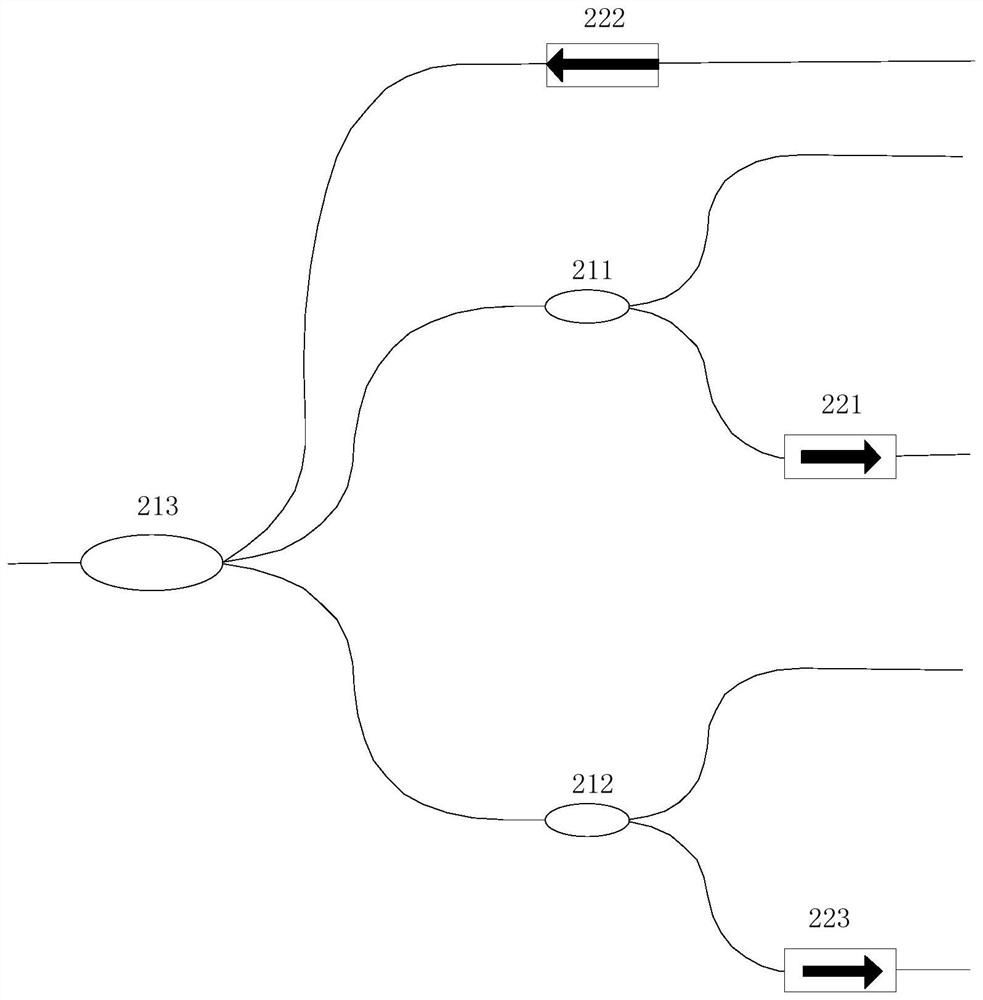

[0035] The invention provides a low-temperature optical fiber sound sensing system, comprising: an optical fiber sound sensing probe, including an acoustic structure, a temperature measuring optical structure, and a light-transmitting optical fiber; an optical fiber branching unit, used for combining light of different wavelengths in the optical fiber and beam splitting; an optical temperature measurement module, used to measure the temperature inside the optical fiber sound sensing probe, using light of the first wavelength; an optical heating module, used to heat the optical fiber sound sensing probe, using light of the second wavelength; optical The sound measurement module is used to restore the light change signal returned by the optical fiber sound sensing probe to sound information, using light of the third wavelength. Wherein, the optical fiber sound sensing probe is placed in a low-temperature acoustic environment for testing, and the first wavelength light emitted by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com