Battery module and new energy automobile

A battery module and cell technology, applied in battery pack components, batteries, secondary batteries, etc., can solve the problems of high cost of multiple bolts, inability to expand modules, and low production efficiency, and achieve convenient integration and thermal insulation. Good, high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to help those skilled in the art to accurately understand the claimed subject matter of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

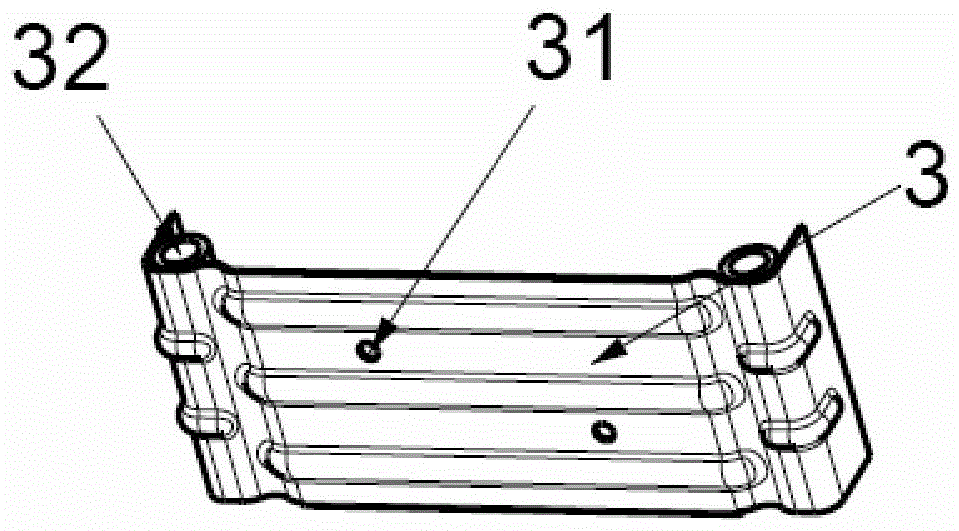

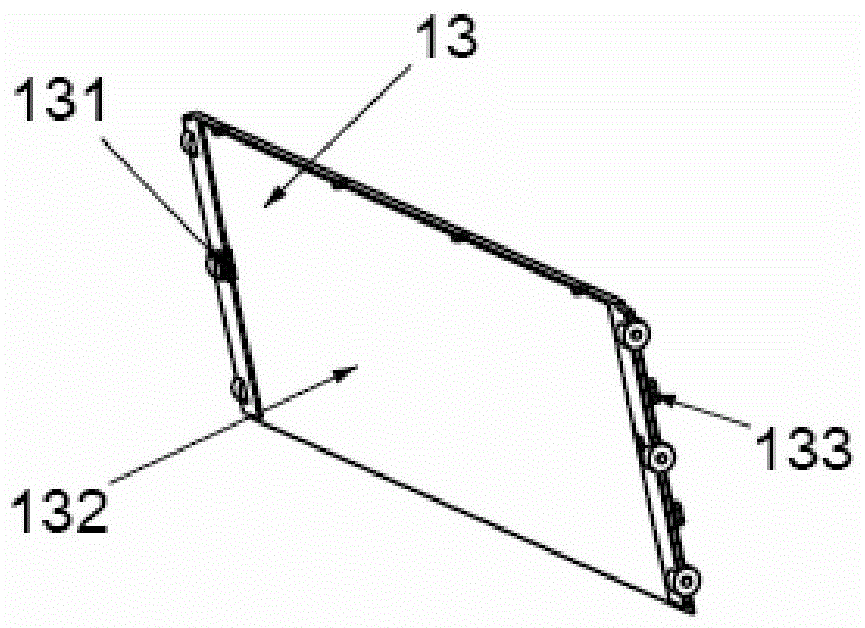

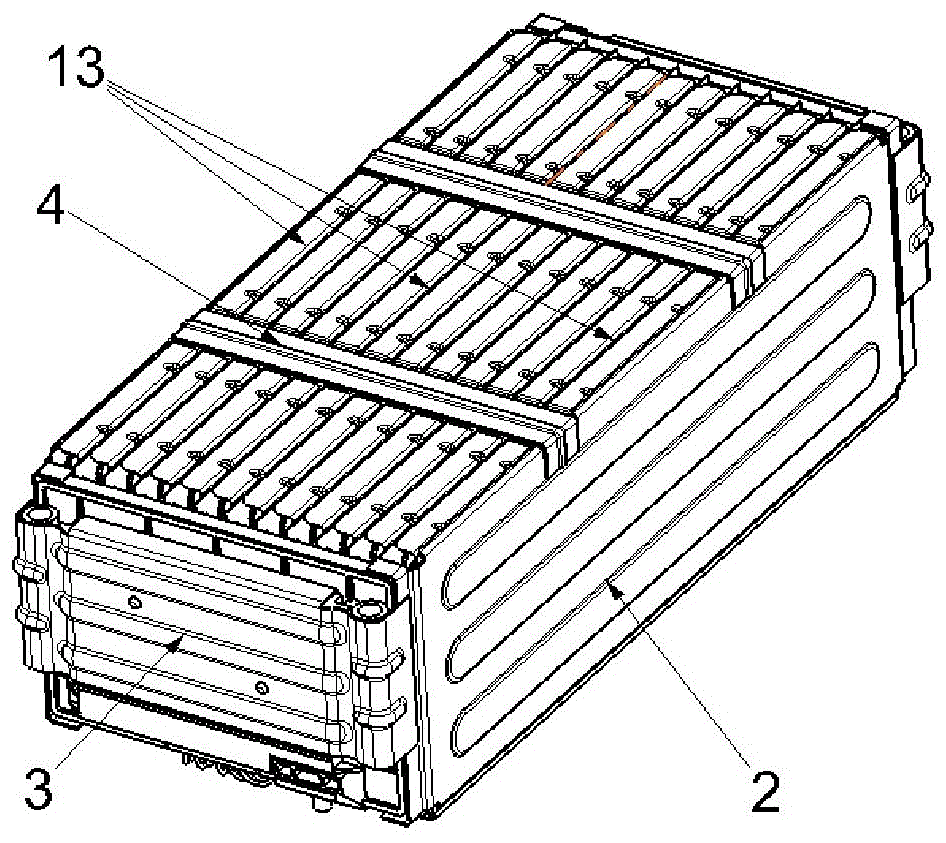

[0035] see Figure 1a -1b is a perspective view of the battery module involved in the present invention, Figure 1a shown as the top of the battery pack, Figure 1b Shown is the bottom of the battery pack. figure 2 An exploded view of the battery module. As can be seen from the above figures, the battery module has a frame structure, which can be an all-metal frame, which includes a top cover 1, two left and right side panels 2, two front and rear baffles 3, and multiple straps 4 at the bottom . The upper cover 1 is connected to the two side panels 2 , the two baffle panels 3 are respectively connected to the two side panels 2 , and a plurality of straps 4 are connected to the two side panels 2 . These co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com