Power battery cooling system of new energy automobile

A new energy vehicle and power battery technology, applied in electric vehicles, secondary batteries, battery/fuel cell control devices, etc., can solve problems such as increasing the cost of battery cooling systems, high phase change material prices, and potential safety hazards. The effect of improving battery life, saving power and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

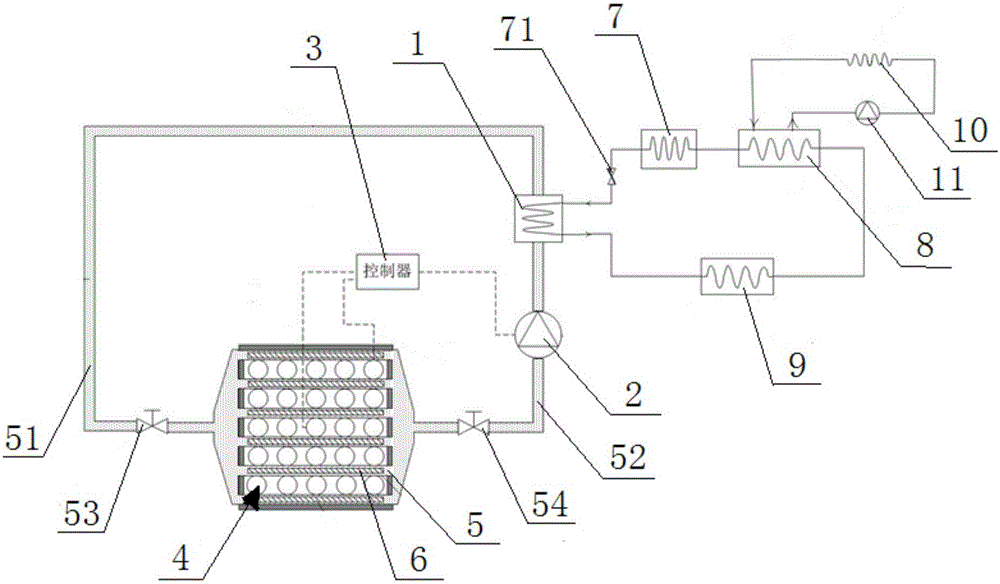

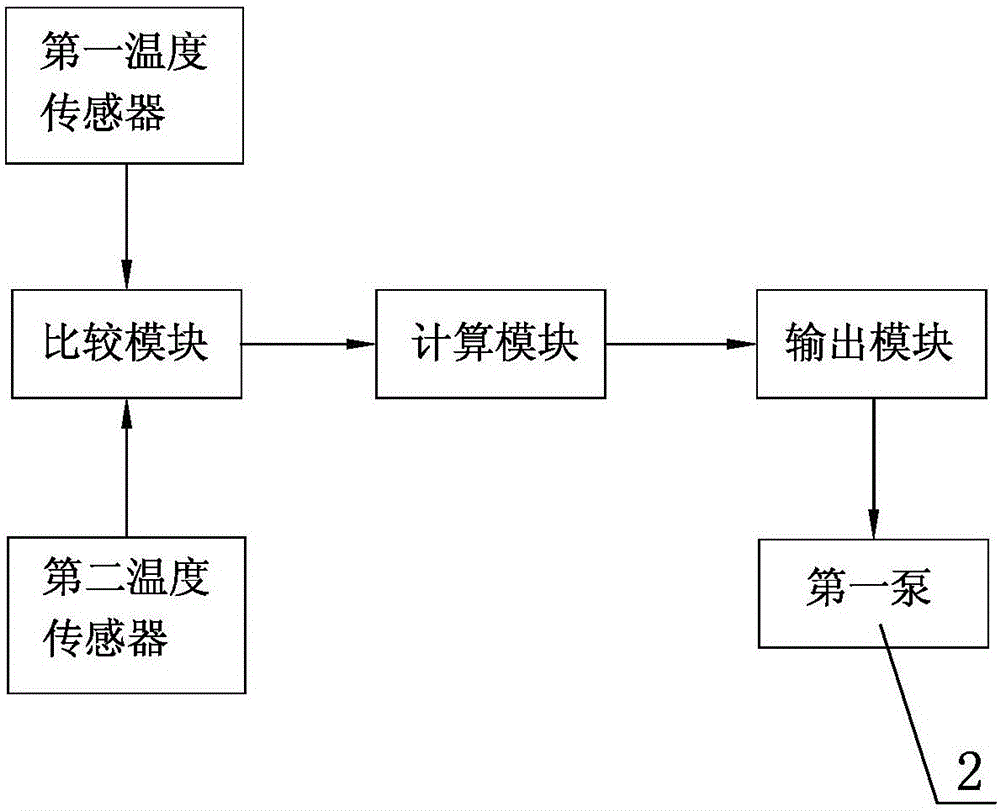

[0022] Embodiment 1: As shown in the figure, a new energy vehicle power battery cooling system includes a heat exchanger 1, a first pump 2, a controller 3 and an absorption refrigeration device connected to the heat exchanger 1. The heat exchanger 1 Connected to the first pump 2, a cooling channel 5 is provided between each group of batteries of the power battery module 4, and a shaped phase change material 6 is arranged in the cooling channel 5, and the phase change temperature range of the shaped phase change material 6 is 40 to 60 ℃, one end of all the cooling passages 5 communicates with the heat exchanger 1 through the first cooling pipe 51, the other end of all the cooling passages 5 communicates with the first pump 2 through the second cooling pipe 52, and the first cooling pipe 51 A first shut-off valve 53 is arranged on the top, a second shut-off valve 54 is arranged on the second cooling pipe 52, a cooling liquid is provided in the first cooling pipe 51 and the second...

Embodiment 2

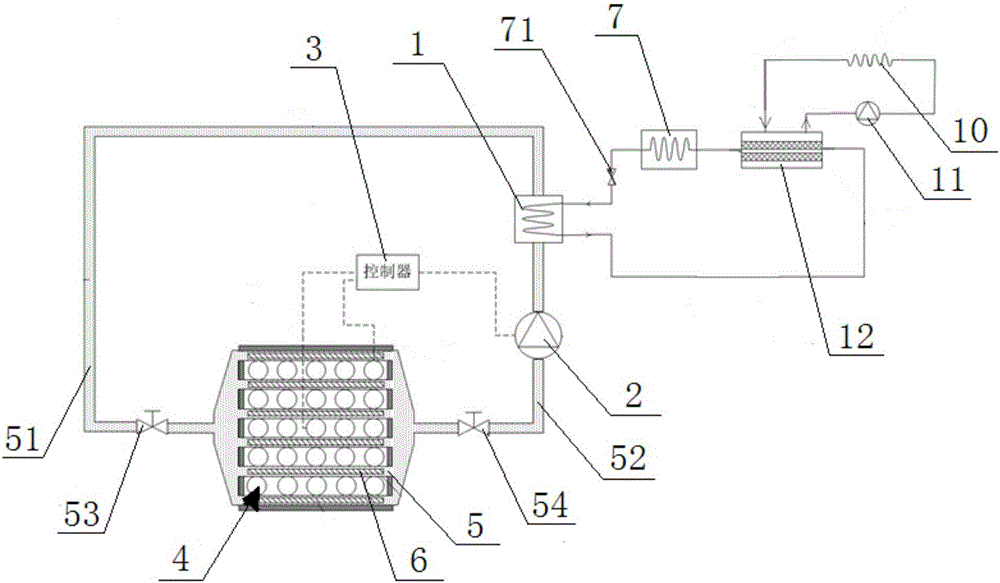

[0025] Embodiment 2: As shown in the figure, a new energy vehicle power battery cooling system includes a heat exchanger 1, a first pump 2, a controller 3 and an adsorption refrigeration device connected to the heat exchanger 1. The heat exchanger 1 Connected to the first pump 2, a cooling channel 5 is provided between each group of batteries of the power battery module 4, and a shaped phase change material 6 is arranged in the cooling channel 5, and the phase change temperature range of the shaped phase change material 6 is 40 to 60 ℃, one end of all the cooling passages 5 communicates with the heat exchanger 1 through the first cooling pipe 51, the other end of all the cooling passages 5 communicates with the first pump 2 through the second cooling pipe 52, and the first cooling pipe 51 A first shut-off valve 53 is arranged on the top, a second shut-off valve 54 is arranged on the second cooling pipe 52, a cooling liquid is provided in the first cooling pipe 51 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com