Automatic tool change detection encoder for CNC (Computer Numerical Control) machine tool

A technology for detecting encoders and machine tools. It is used in manufacturing tools, measuring/indicating equipment, metal processing mechanical parts, etc., and can solve problems such as failure to accurately control mechanism control, difficulty in adjusting cam angle, and delay in starting or stopping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to achieve the above-mentioned purpose, the technical means and mechanism adopted by this patent are now described in detail as follows:

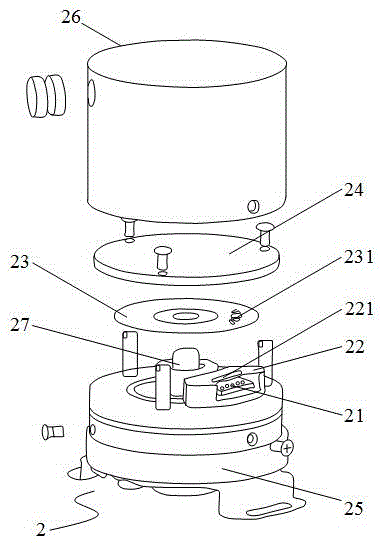

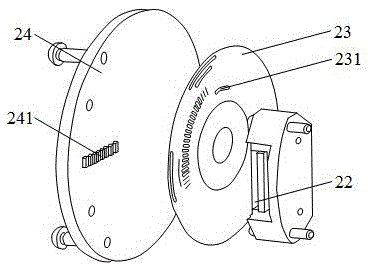

[0020] Please refer to figure 2 and image 3 , respectively are the three-dimensional exploded view and partial schematic diagram of the embodiment. It can be clearly seen from the figure that the CNC machine tool automatically switches the tool to the detection encoder 2, which is an electronic CNC machine tool that can be directly installed on the main shaft or the end of a specific rotating shaft. The automatic tool change detection encoder 2 includes: a light emitting element 21 , a photomask 22 , a grating wheel 23 and a light receiving and processing device 24 .

[0021] The light emitting element 21 emits a beam of light. In this embodiment, the light emitting element 21 is a light emitting diode.

[0022] The light cover 22 is covered on the light emitting element 21, and the light cover 22 is provided with a hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com