Anti-theft oil tank port manufacturing and installing technology

A technology of anti-theft fuel tank and installation process, which is applied in the direction of power unit, transportation and packaging, and the arrangement of the combination with the fuel supply of the internal combustion engine, etc. Quick, easy-to-craft effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

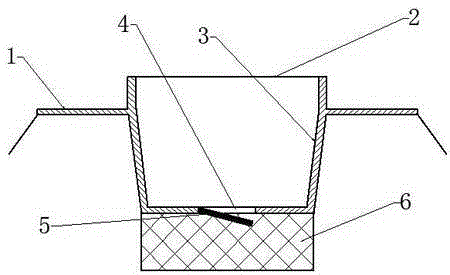

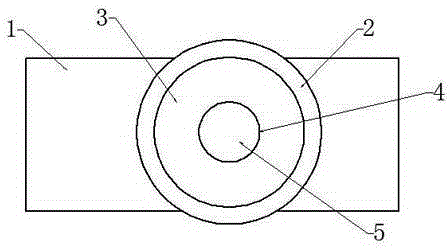

[0010] The present invention will be further described below in conjunction with accompanying drawing.

[0011] Taking the anti-theft fuel tank port as an example, a stainless steel plate is used to stamp and form a refueling cup 3 with an oil filling port 4 on the stamping die of a punching machine—install a one-piece check valve 5 on the oil filling port 4—weld a stainless steel anti-deep hole at the bottom of the refueling cup 3 Inserting the mesh cover 6—Installing the refueling cup 3 that removes the processing sharp corner burr as a whole in the fuel tank port 2 of the fuel tank 1, and welding it firmly—overall inspection and functional experiment.

[0012] Functional experiment process: the refueling gun extends from the fuel tank port 2 into the bottom of the refueling cup 3, and opens the one-way valve 5 to insert fuel into the fuel tank 1 to refuel. When the oil filling port 4 intubate of 3 took fuel oil, the anti-deep insertion net cover 6 would hinder the oil extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com