Robot platform for wind driven generator blade detection

A technology for wind turbines and robots, applied in the field of robot platforms, can solve the problems of large influence of weather and environment, low efficiency, unsafe worker's safety, etc., and achieves the effects of strong wall adaptability, simple control, and easy steering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

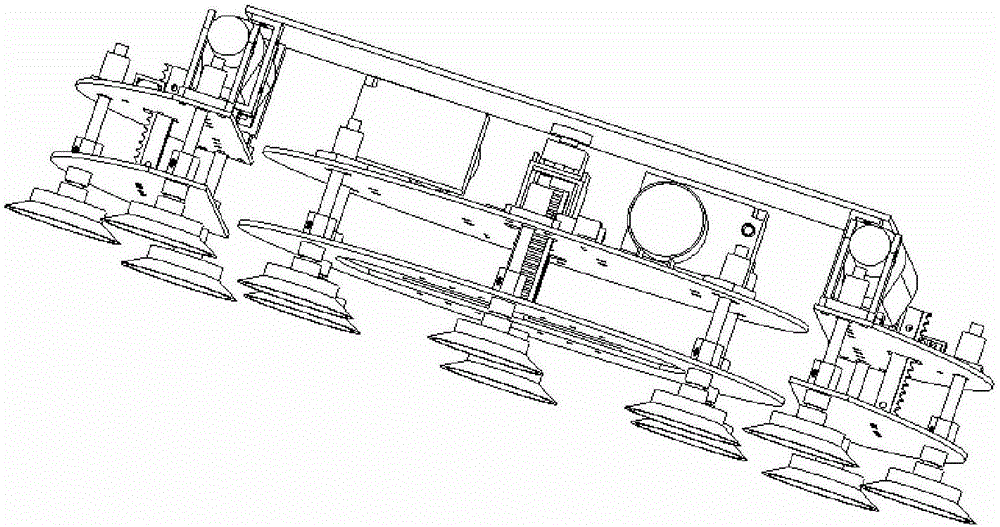

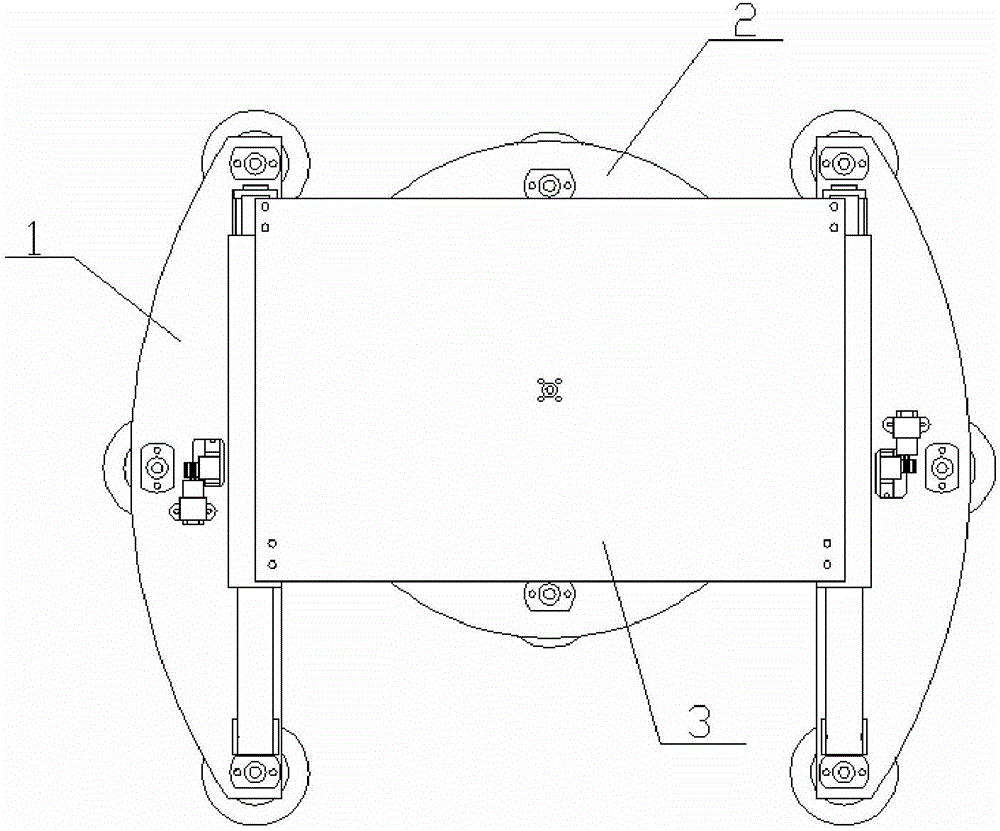

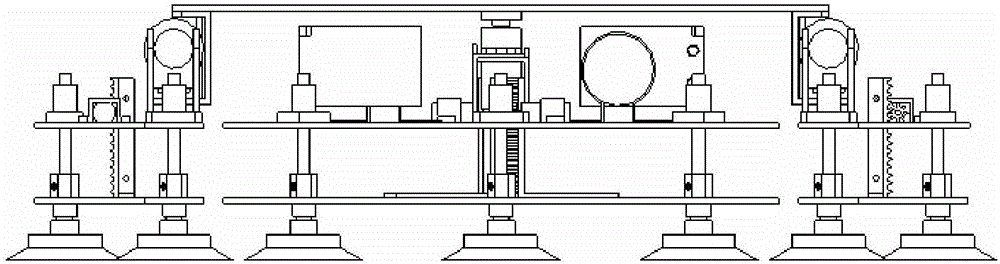

[0021] Embodiment 1, the present invention comprises connecting plate 3, two straight-ahead devices 1, steering device 2, straight-ahead device 1 is used for the forward and backward of robot, and steering device 2 is used for changing the straight-ahead direction of robot; The structure of described two straight-ahead devices 1 It is exactly the same, symmetrically installed on both sides below the connecting plate 3; the steering device 2 is installed at the center below the connecting plate 3; the straight running device 1 includes two support frames 19, two sliders 12, and two guide rails 15 , straight top plate 11, straight bottom plate 10, three suction cup assemblies, obstacle-crossing assembly, push-pull rod 17; the lower end of the support frame 19 is fixed on the slider 12, the slider 12 is set on the guide rail 15, and the guide rail 15 is fixed on the straight top plate 11 , the straight running top plate 11 is located directly above the straight running bottom plat...

Embodiment 2

[0022] Embodiment 2, the obstacle-crossing assembly includes a DC deceleration motor 14, a gear, a rack 18, and a fixed plate 13; the DC deceleration is respectively installed on the straight top plate 11 and the turning top plate 21, and the DC deceleration motor 14 shaft ends are equipped with gears, The gear is connected with the rack 18, the rack 18 is installed on the fixed plate 13, and the fixed plate 13 is respectively installed on the straight bottom plate 10 and the steering bottom plate 22, and the forward and reverse rotation of the DC gear motor 14 can drive the corresponding sucker 9 to move up and down. Thereby, obstacle surmounting and adsorption are carried out. refer to Figure 1 to Figure 8 , all the other are with embodiment 1.

Embodiment 3

[0023] Embodiment 3, the suction cup assembly includes a suction cup 9, a ball hinge, fittings 5, and a linear bearing 6; the suction cup 9 is connected to one end of the ball hinge through threads, and the other end of the ball hinge is threaded to respectively go straight to the bottom plate 10 and turn to the fittings 5 on the bottom plate 22 The lower ends are connected, and there is a ventilation hole 7 on the fitting 5, and the upper end of the fitting 5 is set in the linear bearing 6, and the linear bearing 6 is respectively installed on the straight top plate 11 and the turning top plate 21, and the upper end of the fitting 5 forms a rolling connection with the linear bearing 6, which can Reduce the resistance generated when the fitting 5 moves. refer to Figure 1 to Figure 8 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com