Ball bearing assembly

A ball bearing and bearing set technology, applied in the field of bearings, can solve the problems of insufficient axial load thrust capacity, weakened practicability and mass production, difficult low friction and stable operation, etc., to improve the uniform bearing load and solve the axial load. Insufficient load thrust capacity and shaft core movement problems, the effect of strong assembly and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

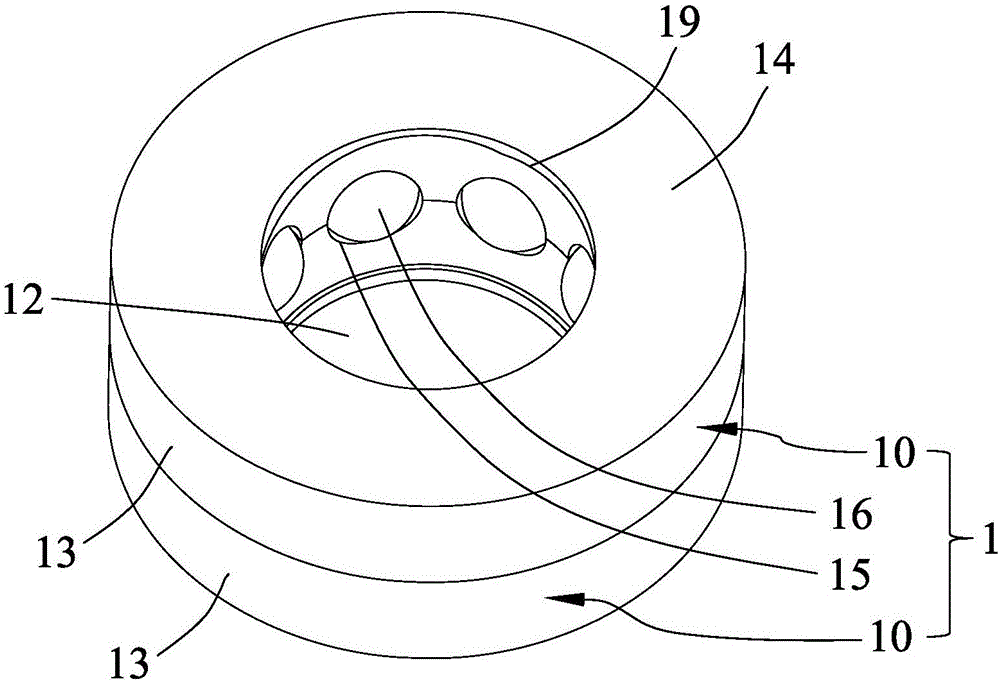

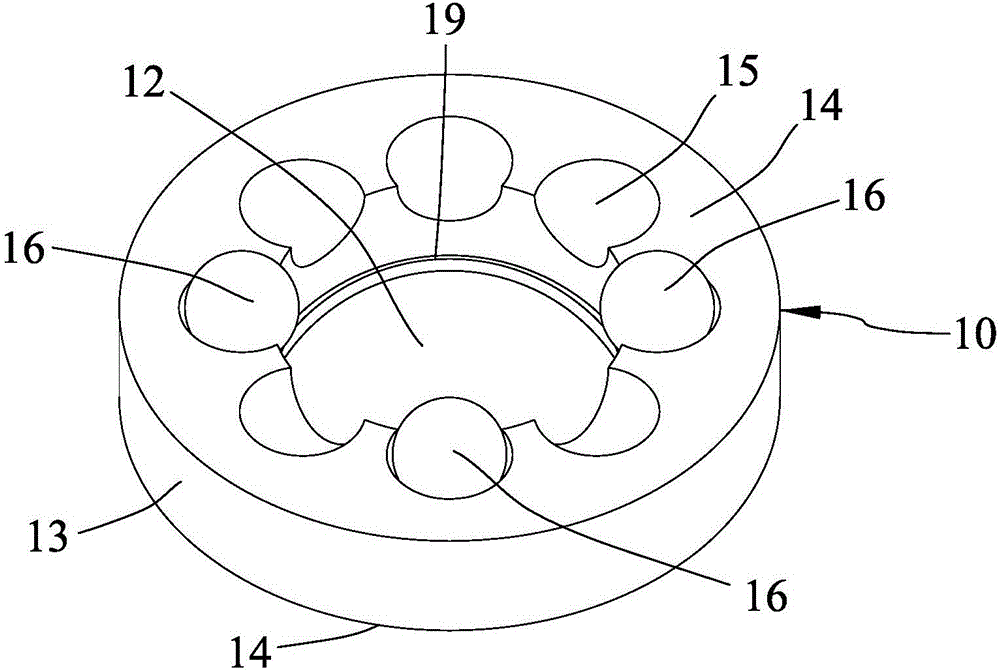

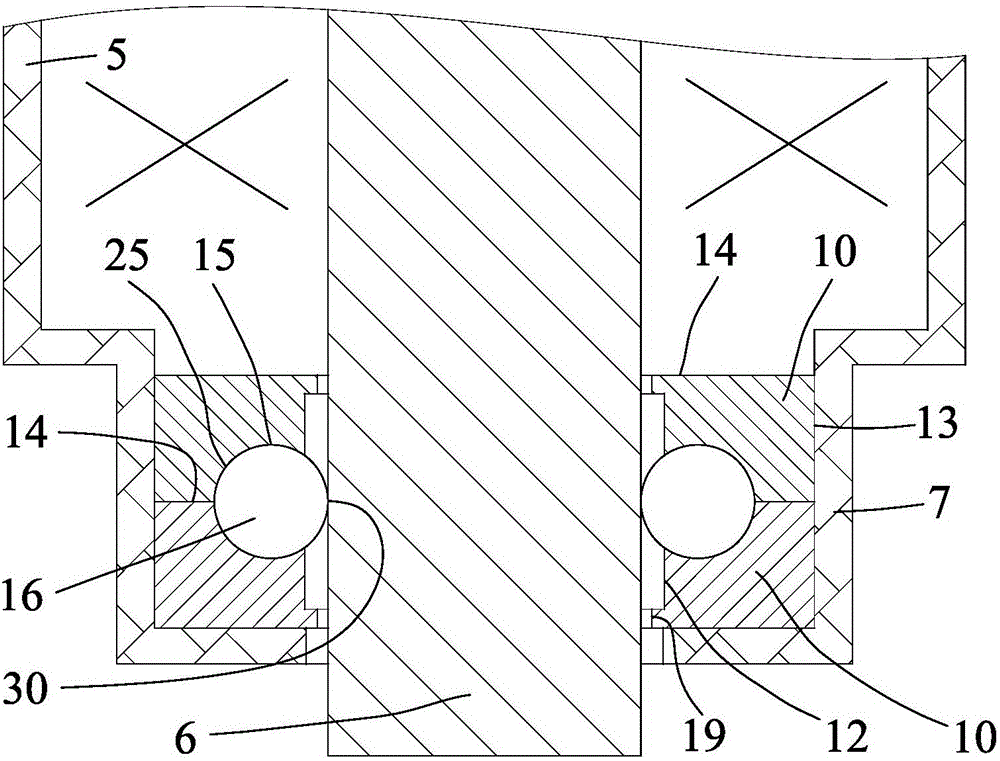

[0028] Figure 1 to Figure 3 According to the first embodiment of the present invention, the ball bearing assembly includes a bearing set 1, which is composed of two unit parts 10 made of dense or porous materials butted in the axial direction and a plurality of spherical balls 16 arranged therebetween. In each drawing of the invention, eight balls are taken as an example; each unit element 10 includes an assembly part 13 formed by an outer peripheral surface and two connecting parts 14 formed by two end faces, and the two connecting parts 14 are formed through the two connecting parts 14 in the axial direction. A circular central through hole 12, and a plurality of hemispherical recesses 15 recessed on a concentric circle surrounding the central through hole 12 at a connecting portion 14, the plurality of hemispherical recesses 15 are used to place the A plurality of balls 16, the curvature of each recess 15 matches the ball 16, and makes the balls 16 arranged in each recess ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com