Feed beating and cleaning device

A technology for cleaning devices and feeds, which is used in feed, grain processing, cleaning of hollow objects, etc., can solve the problems of small distance between rotating racks and grinding inclined bars, device blockage, device damage, etc., and achieves rapid cleaning and rapid water inflow. , the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

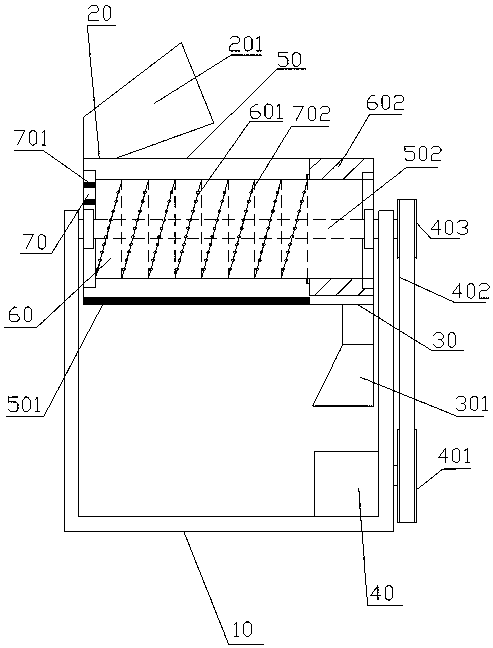

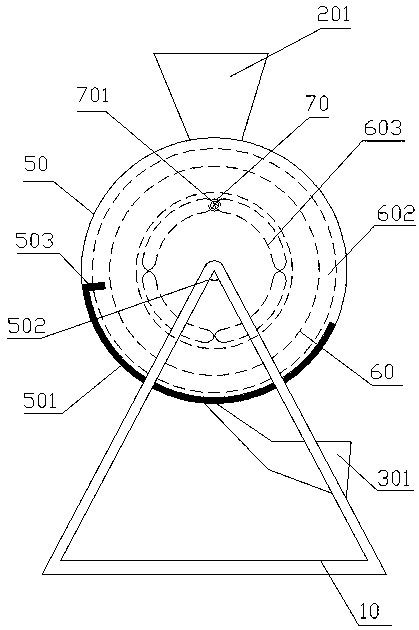

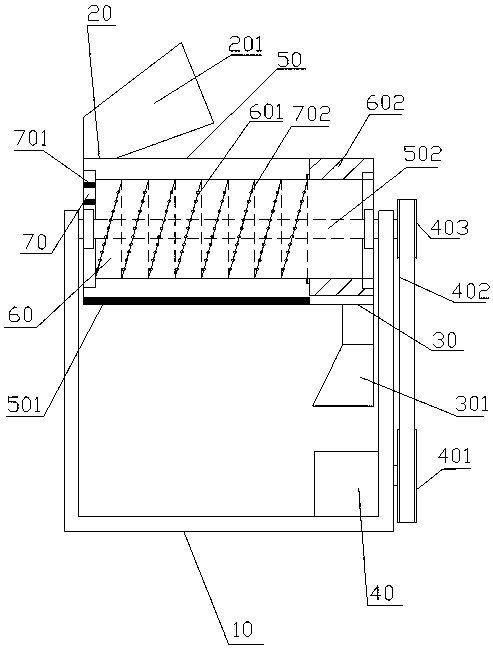

[0017] Embodiment 1 is basically as attached figure 1 And attached figure 2 Shown: a feed beating and cleaning device, including a frame 10, a motor 40, a grinding device and a transmission device, the motor 40 is fixedly installed on the lower end of the frame 10, the transmission device is connected with the grinding device and the motor 40, and the grinding devices are all fixed Installed on the rack 10. The transmission device includes a driving wheel 401, a driven wheel 403 and a transmission belt 402. The driving wheel 401 is connected to the power output end of the motor 40, and the driven wheel 403 is connected to the driving wheel 401 through the transmission belt 402. The entire transmission device is vertically arranged to realize fast power transmission. .

[0018] The grinding device comprises a barrel 50 and a grinding barrel 60. The upper left end of the barrel 50 is provided with a feed port 20, the feed port 20 is provided with an introduction pipe 201, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com