Method for efficiently transferring heat and mass by utilizing turning wheel and system

A heat and mass transfer, runner technology, applied in the field of efficient heat and mass transfer, can solve the problems of increased system complexity, increased manufacturing difficulty, and the size of the runner should not be too large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

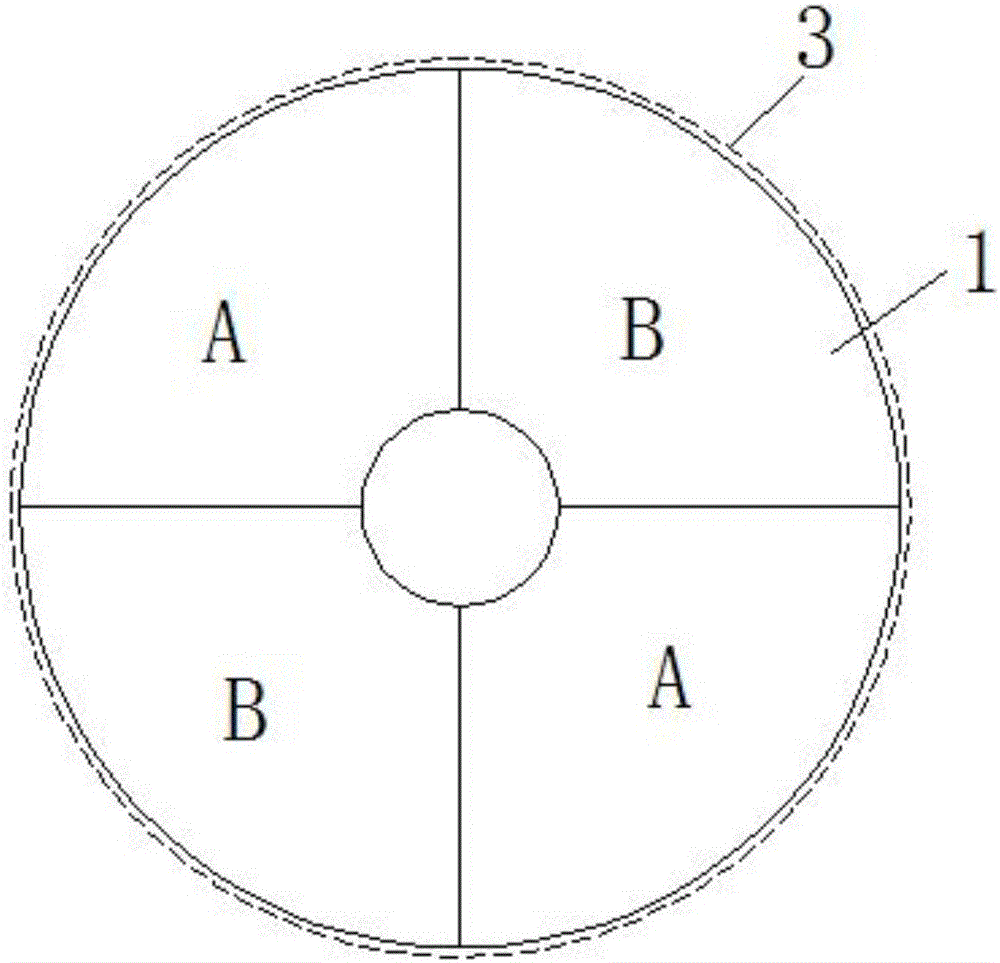

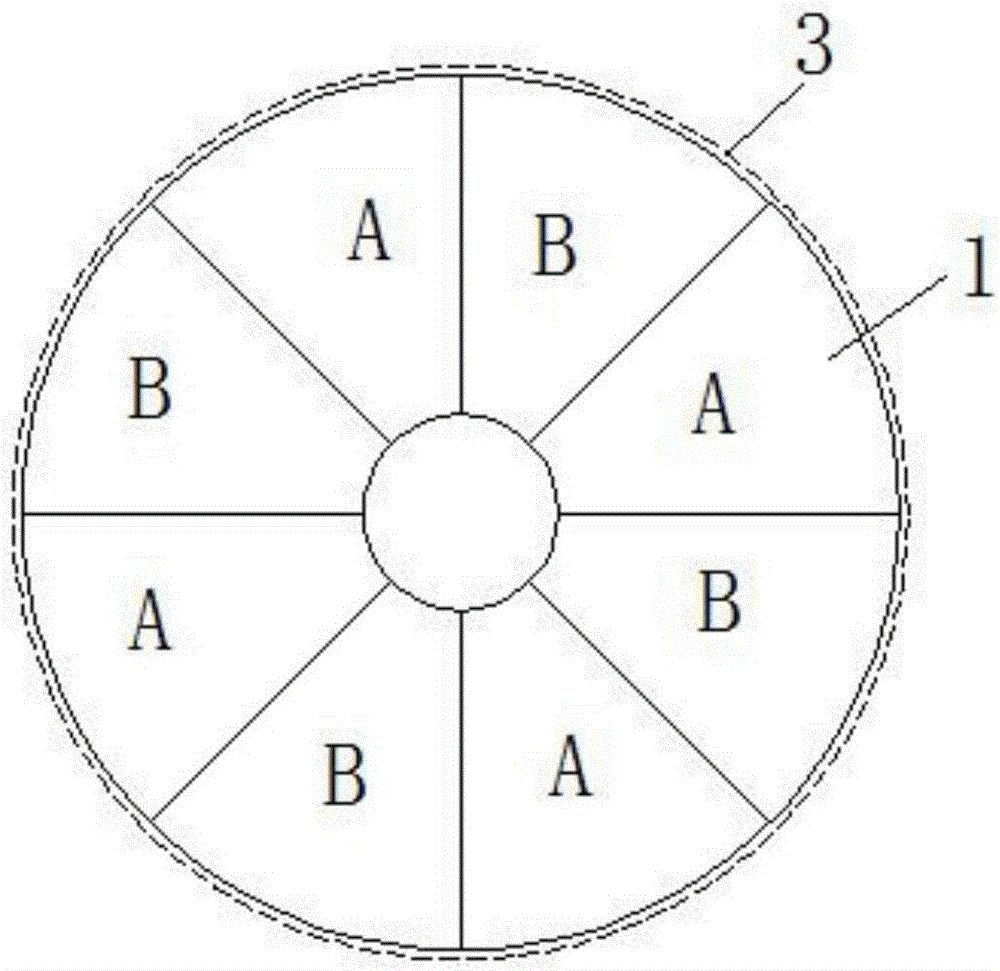

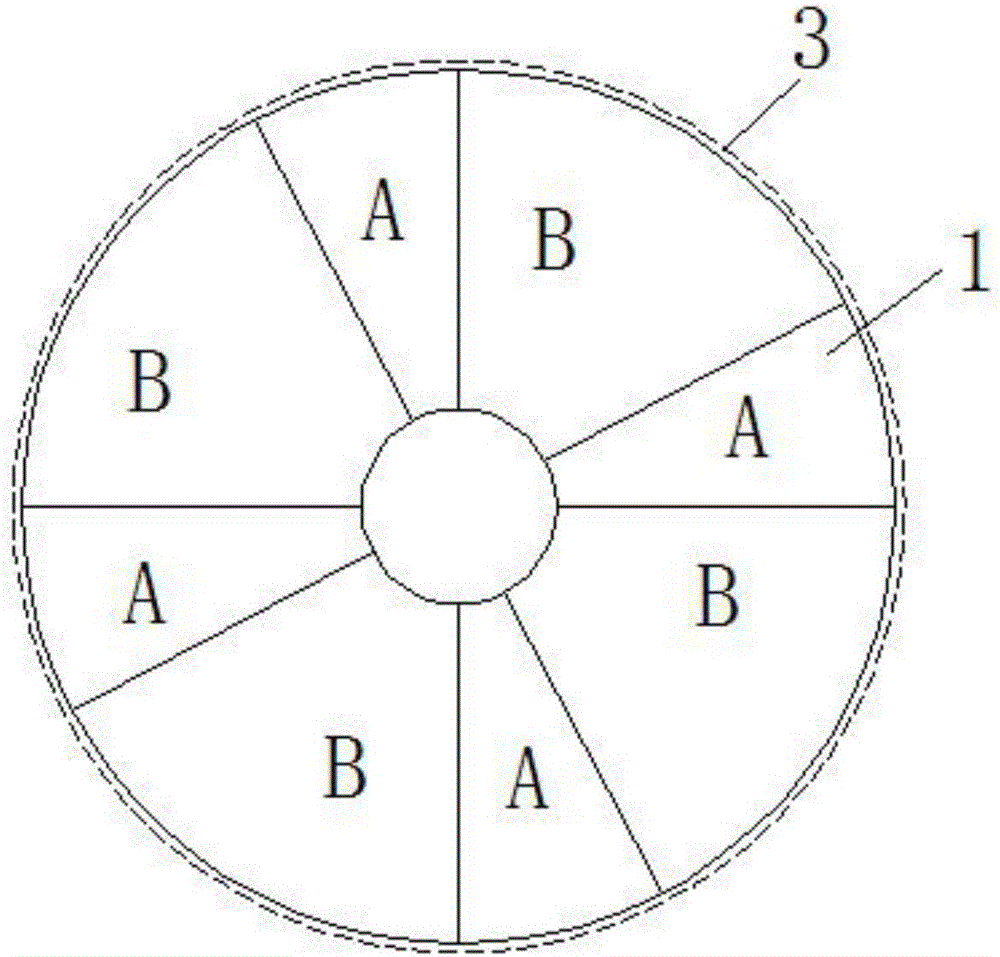

[0024] Such as Figure 5 As shown, the system includes a runner 3, and a first wind guide device 1 and a second wind guide device 2 with the same structure. The first wind guide device 1 and the second wind guide device 2 are located on both sides of the runner 3 respectively. Both the air guiding device 1 and the second air guiding device 2 comprise a plurality of first passages and a plurality of second passages, the first passages and the second passages are arranged alternately and are isolated from each other; the passage walls are closely connected to the ventilation surface of the runner 3 touch. The first air guide device 1 on the side of the runner 3 divides the two streams of A and B gases entering the runner 3 into two groups, the A air enters the first channel, and the B air enters the second channel. Figure 8 and 9 The form shown is realized, including the air guide tube 10, the channel wall 13 and the channel sealing plate 14, thereby constituting the inner ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com